Process dynamic control scheme for bulkhead distillation column with partition plate at middle-lower part

A technology for dynamic control of the next-wall rectification tower, which is applied in the directions of distillation adjustment/control, fractionation, distillation separation, etc., and can solve problems such as difficult control of the next-wall rectification tower, product quality requirements, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A Dynamic Control Scheme of Dividing Wall Distillation Column with Partition in the Middle and Lower Part

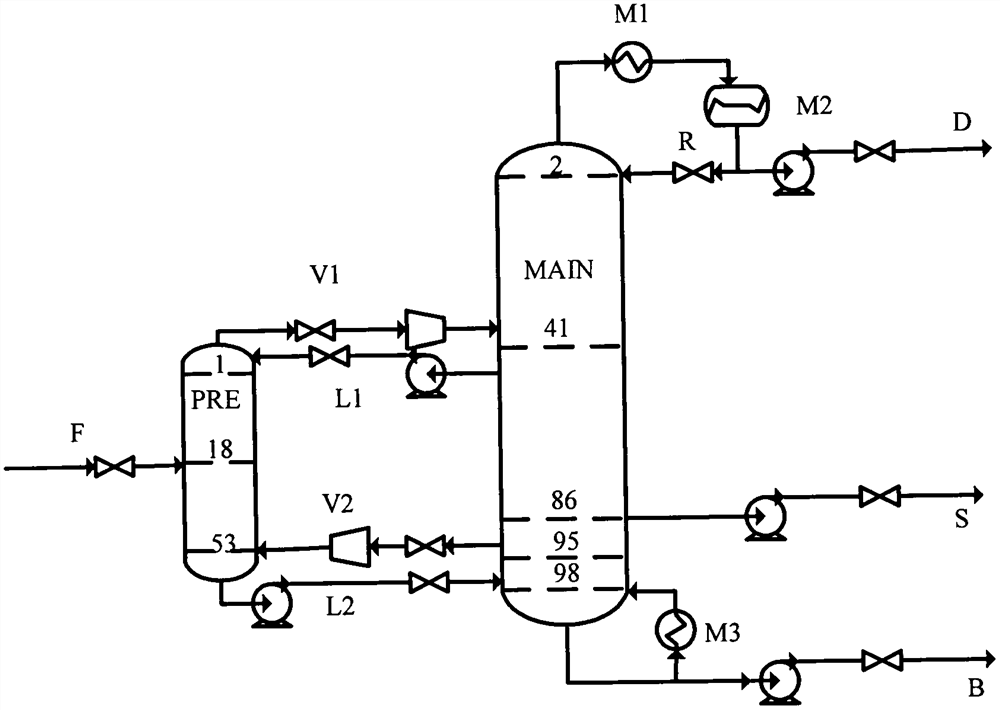

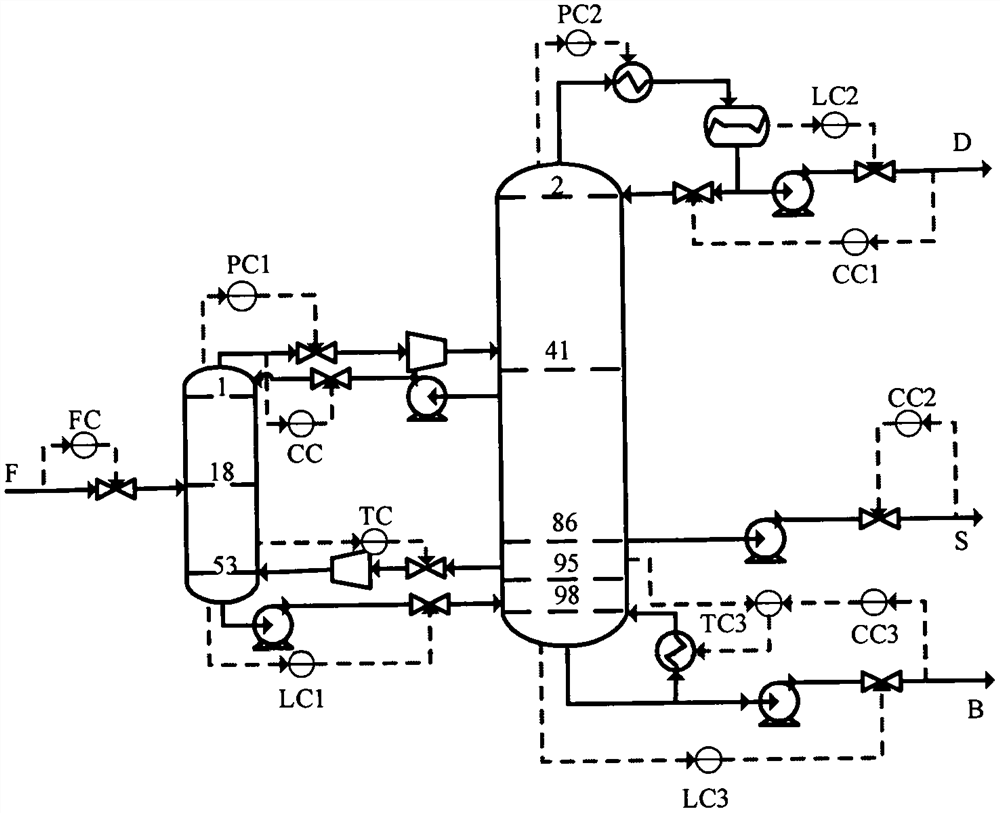

[0034] figure 2 It is a schematic diagram of a process dynamic control scheme of a dividing wall rectification column with partitions in the middle and lower parts. Taking the separation of the ternary mixture of isopentane, n-pentane and n-hexane as an example, the light component isopentane is extracted from the top of the main tower, the middle component n-pentane is extracted from the side line, and the heavy component n-hexane is extracted from the main column. Extracted from the bottom of the tower. Its process flow diagram is as follows figure 1 shown. The control loop of the present invention is as follows:

[0035] (1) Feed flow control loop, including for adopting flow controller to control the feed flow into the pre-separation tower;

[0036] (2) The pressure control circuit at the top of the tower, including using a pressure controller to control...

Embodiment 2

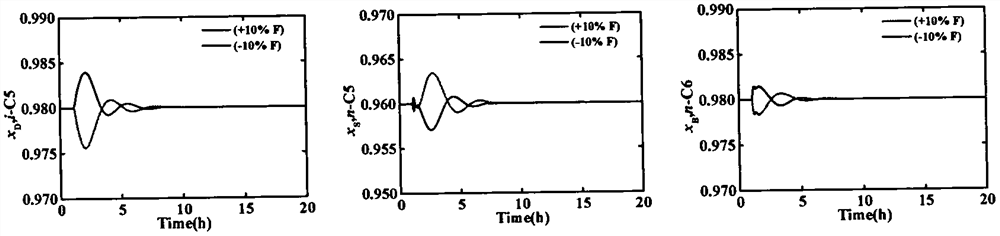

[0042] The process dynamic control scheme of the dividing wall rectification column with the partition plate in the middle and lower part of the control structure described in Example 1 is adopted, and the separation of isopentane, n-pentane and n-hexane is taken as an example. After the process runs smoothly for 1 hour, the feed flow rate changes by ±10%, from the original 300kmol / h to 330kmol / h or 270kmol / h, from image 3 It can be seen from the figure that through the function of the control loop, the product purity returns to the original set value in a short time and with a small overshoot under the disturbance of the flow rate ±10%. The maximum overshoot does not exceed 0.005, the longest time does not exceed 7h, and the final product purity returns to the set value, indicating that the control loop can well deal with disturbances within ±10%, and has good robustness and stability.

Embodiment 3

[0044] The process dynamic control scheme of the dividing wall rectification column with the partition plate in the middle and lower part of the control structure described in Example 1 is adopted, and the separation of isopentane, n-pentane and n-hexane is taken as an example. After the process runs smoothly for 1 h, the feed composition isopentane changes ± 10%, and the mole fraction changes from the original 0.33 to 0.363 or 0.297, from Figure 4 It can be seen from the figure that through the function of the control loop, the product purity returns to the original set value in a short time and with a small overshoot under the disturbance of the composition ±10%. The maximum overshoot does not exceed 0.002, the longest stabilization time is 7 hours, and the final product purity returns to the set value, indicating that the control loop can well deal with disturbances within ±10%, and has good robustness sex and stability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com