Wing-shaped structure, heat exchange plate, heat exchanger and heat exchange method

A heat exchange plate and airfoil technology, applied in airfoil structure, heat exchange plate, heat exchanger and heat exchange field, can solve the problems of limited space for heat transfer capacity improvement, easy scaling, blockage of flow channels, etc. Effects of nucleation and growth, number reduction, flow strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In view of this, the present invention provides a airfoil structure, a heat exchange plate, a heat exchanger, and a heat transfer method, which has a high heat transfer efficiency, and can reduce the deposition of scale-based substances, which is more suitable for practical purposes. .

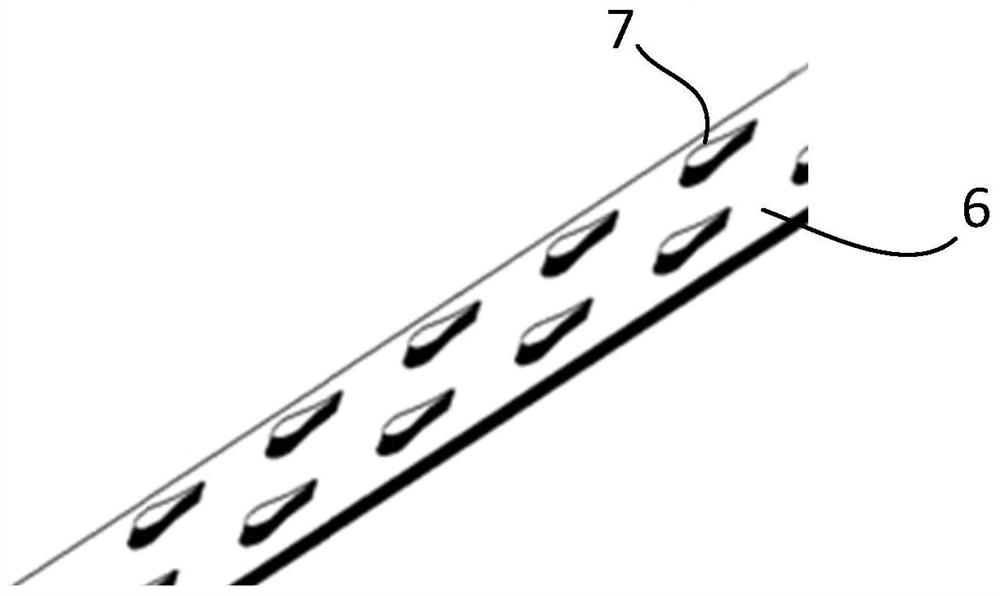

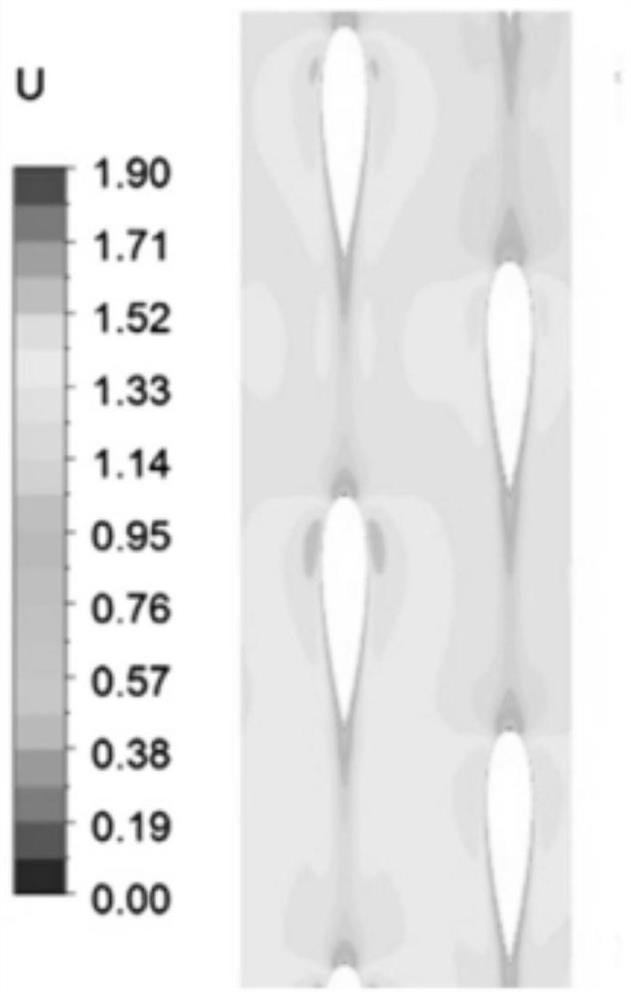

[0045] The inventors have been hard work, found that in the prior art, see figure 1 Attachment figure 2 Attach image 3 During the operation of the heat exchanger with the airfoil structure 7, although the inlet is provided with a filter, the fluid is inevitably containing some impurities. After a long run, it will scale in the airfoil channel, resulting in clogging or change The heat effect decreases. In addition, from the distribution of the flow rate of the airfoil channel, such as image 3 As shown, the width of the airfoil structure is faster, that is, the high speed region 4 is formed here, and the heat exchange effect is best. The fluid shocks to the leading edge of the airfoil structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com