Antibacterial filter material production device

A technology for production device and filter material, which is applied in filtration and separation, membrane filter, textile material processing, etc., can solve the problems of affecting the health of workers, low production efficiency of antibacterial filter materials, uneven distribution of antibacterial agent liquid, etc. Avoid quality and antibacterial properties, dry thoroughly and thoroughly, and improve the effect of drying treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

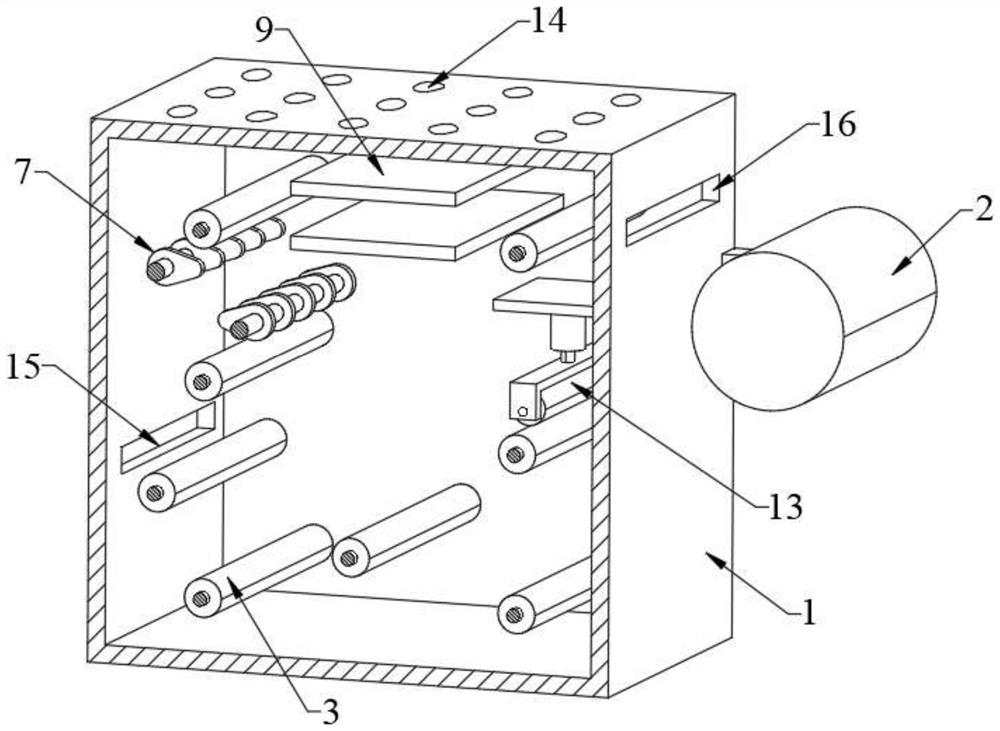

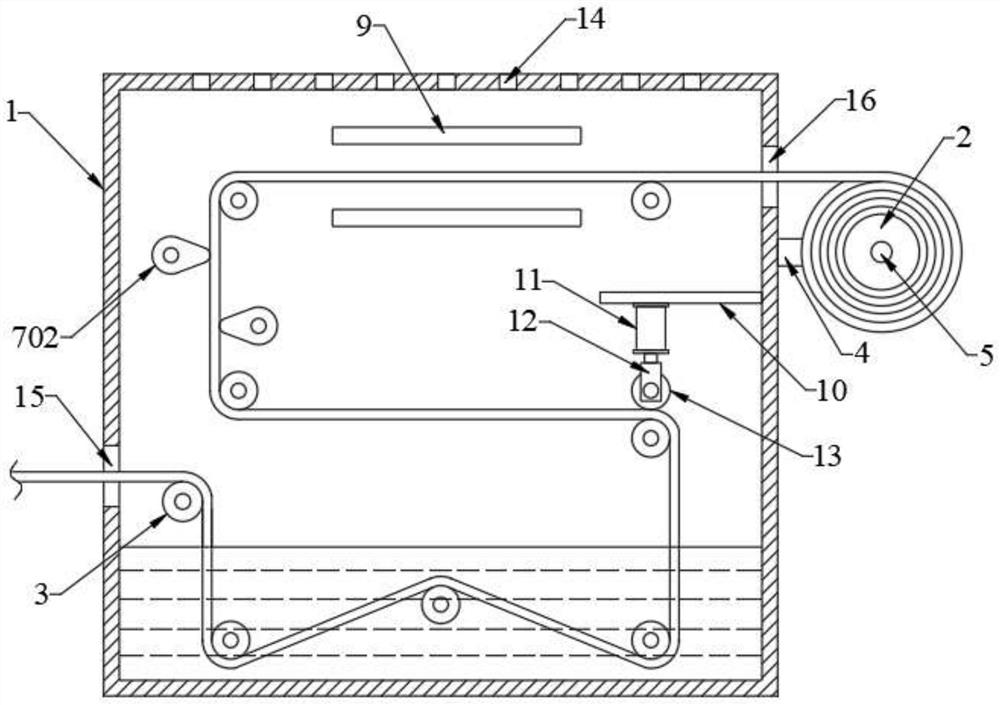

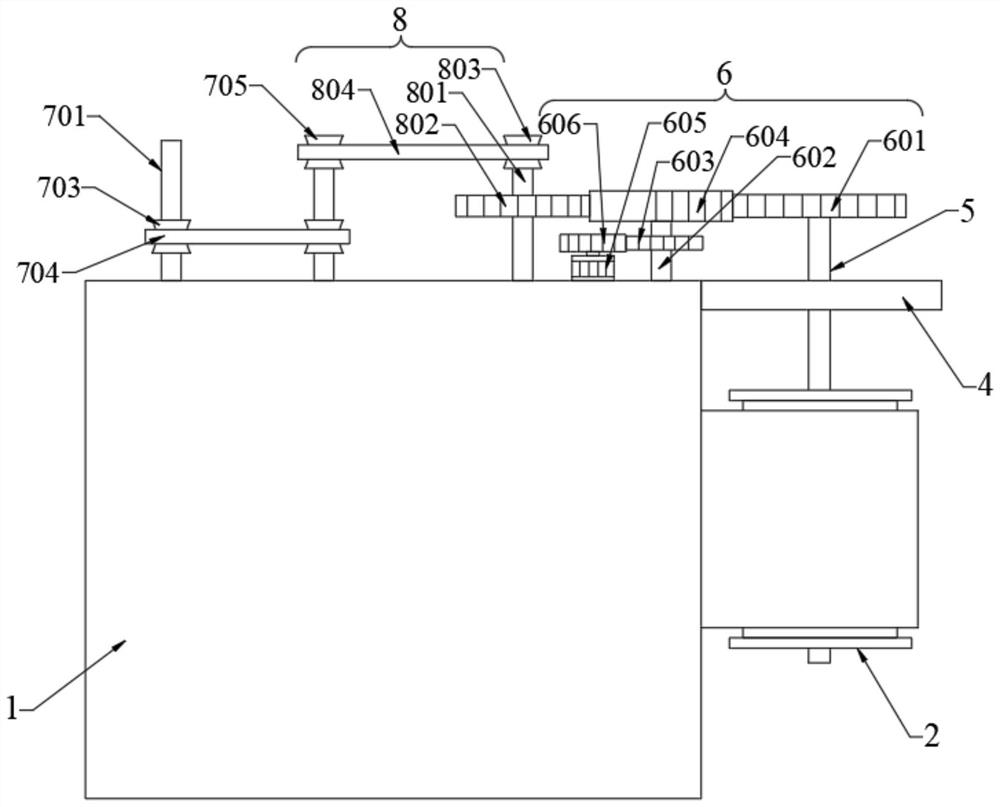

[0027] see Figure 1-3 , an antibacterial filter material production device, comprising a treatment box 1 and a rewinding roller 2 for winding the filter material, the inner front and rear walls of the treatment box 1 are rotatably connected with a plurality of guide wheels 3, and the right wall of the treatment box 1 is fixedly connected with a support rod 4, The support rod 4 is rotatably connected with a driving rod 5, the receiving roller 2 is fixedly connected to the outer wall of the driving rod 5, the front end of the supporting rod 4 is connected with a driving mechanism 6 for driving the receiving roller 2 to rotate, and a device inside the processing box 1 is installed to drive the filter material to vibrate. The vibration mechanism 7 of the processing box 1 is equipped with a linkage mechanism 8 connected to the drive mechanism 6 on the rear wall of the processing box 1. Two sets of drying devices 9 are installed inside the processing box 1. By bringing the filter ma...

Embodiment 2

[0033] see Figure 1-2 with Figure 5 , on the basis of Embodiment 1, the right wall of the inner cavity of the processing box 1 is fixedly connected with a crossbar 10, and the lower end of the crossbar 10 is fixedly connected with an electric telescopic rod 11, and the telescopic end of the electric telescopic rod 11 is fixedly connected with a connecting frame 12, connected Squeeze roller 13 is rotatably connected in frame 12. After the filter material passes through guide wheel 3, start electric telescopic rod 11 to drive connecting frame 12 and squeeze roller 13 to descend, and the filter material below is contacted by squeeze roller 13, and can Adjust the descending distance of the squeeze roller 13 according to the filter material of different thicknesses and the specific conditions. After the filter material is immersed in the antibacterial agent liquid, it passes between the guide wheel 3 and the squeeze roller 13. Most of the accumulated antibacterial agent solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com