Washing-resistant alginate fiber and preparation method thereof

A seaweed fiber, washing-resistant technology, applied in the chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., can solve the problems of affecting the spinning effect and difficult to control the spinning process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Preparation of spinning solution:

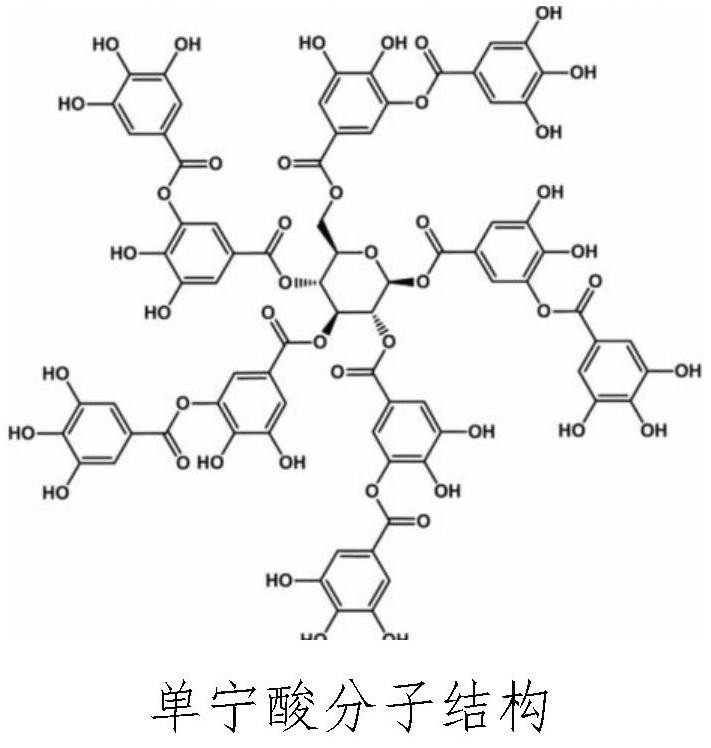

[0050] At room temperature, 30g of sodium alginate, 5g of tannic acid, and 1000g of water were used to prepare the spinning solution, and the concentration was 0.1035mol / L of NaHCO 3 The solution is used as a regulator to adjust the pH value of the spinning solution to 10;

[0051] (2) Preparation of washing-resistant seaweed fiber:

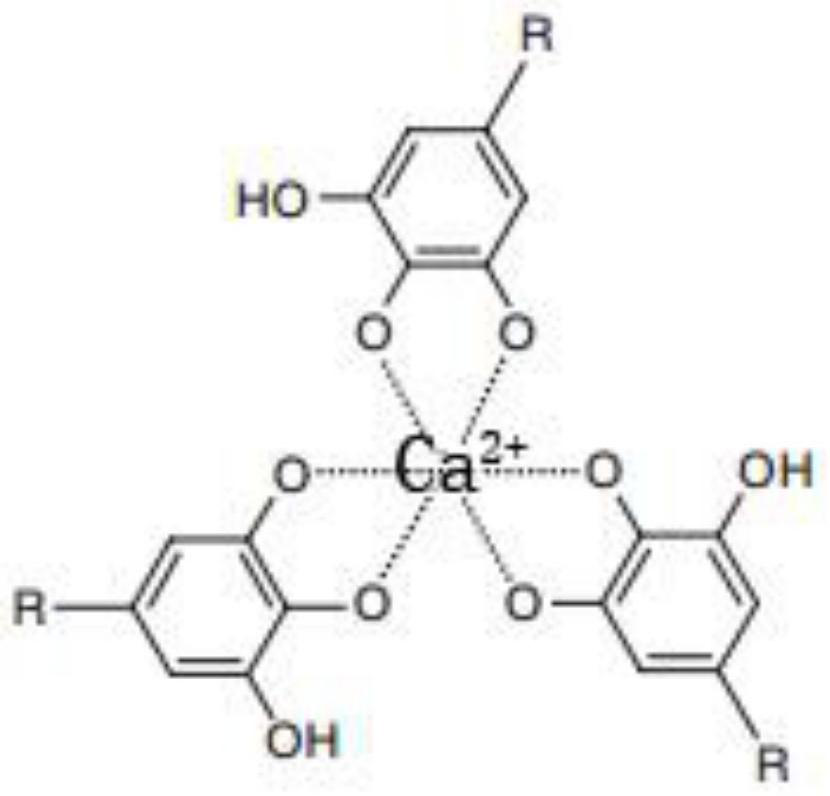

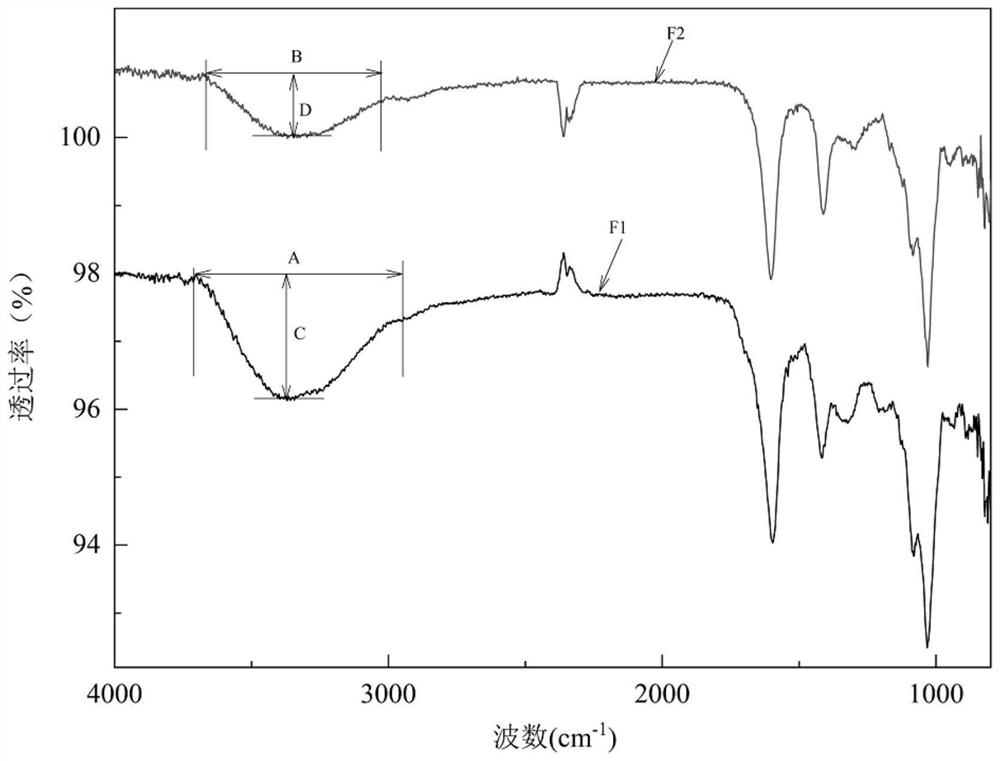

[0052] The spinning solution prepared in step (1) is mechanically stirred at a temperature of 45°C, defoamed and left to stand under vacuum conditions, and then the spinning solution is spun and extruded to a temperature of 50°C by a wet method or a dry spray wet method. , the concentration is that cross-linking reaction is carried out in 4.5wt% calcium chloride coagulation bath, coagulates through coagulation bath, makes the five-membered ring chelate that contains cross-linking network and the primary fiber of hydrogen bond cross-linking network structure, then through washing, Drawing and drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com