Low-mutual-diffusion and high-temperature-oxidation-resistant coating for copper conductor and preparation method thereof

A technology of anti-high temperature oxidation and copper conductor, which is applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of insufficient copper conductor oxidation resistance, coating interdiffusion, low interdiffusion, etc. The process is green and pollution-free, the process is simple, and the effect of efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

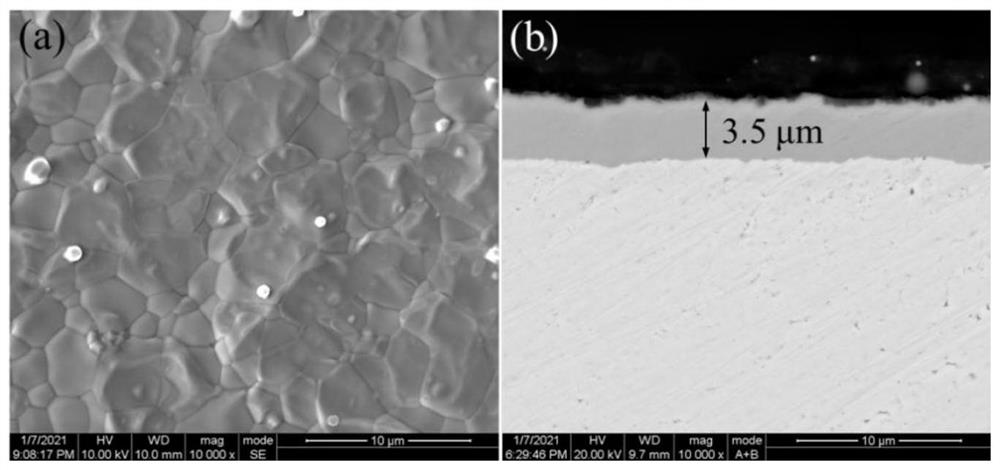

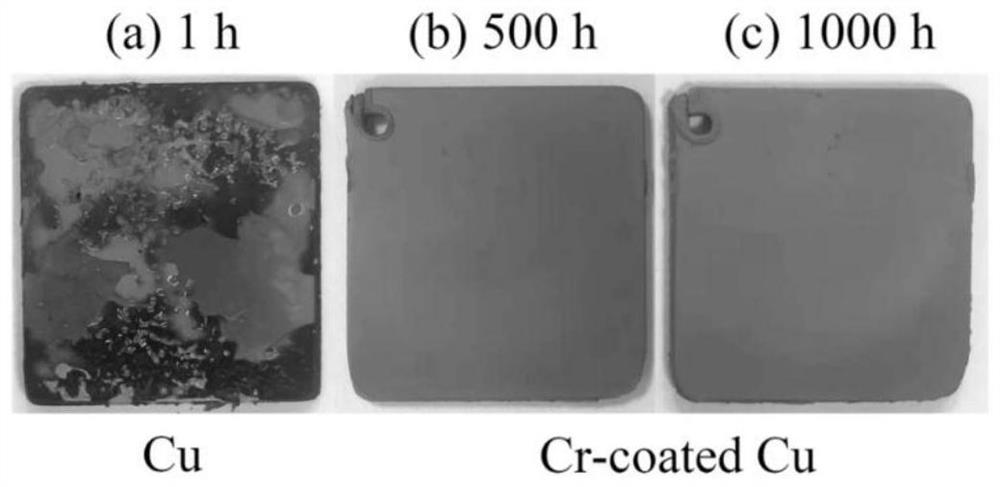

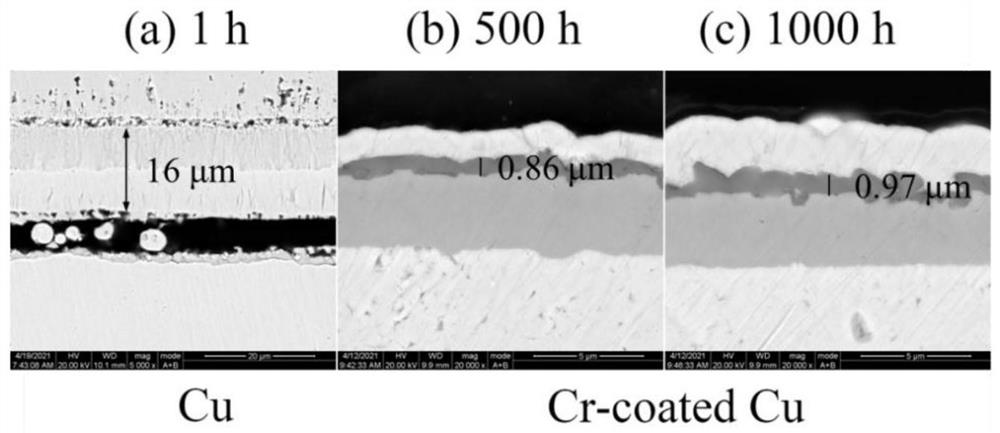

[0030] This example illustrates the preparation of low interdiffusion and high temperature oxidation resistant coatings for copper conductors by multi-arc ion plating and its preparation method. First, install the pure chromium target on the cathode water-cooled target sleeve, hang the copper sheet substrate in front of the target, close the vacuum chamber door, and carry out pumping; the vacuum degree of the back of the chamber reaches 10 -3 When Pa level or lower, open the pressure valve to feed Ar gas into the vacuum chamber to maintain the vacuum at 2-3Pa, set the bias voltage in the range of -700V--1000V, and perform glow cleaning on the substrate surface for about 10 minutes. Then close the pressure valve to maintain the vacuum at 10 -3 Pa; The cathodic arc is directly ignited by the arc pilot by the contact method. In this example, the arc current is 200A, the pulse bias voltage is -100V, the duty cycle is 20%, and the time is 20min. The surface and cross-sectional sc...

Embodiment 2

[0034] This example illustrates the preparation of low interdiffusion and high temperature oxidation resistant coatings for copper conductors by multi-arc ion plating and its preparation method. First, install the pure chromium target on the cathode water-cooled target sleeve, hang the copper parts in front of the target, close the vacuum chamber door, and pump air; the vacuum degree of the back of the chamber reaches 10 -3 At Pa level or lower, open the pressure valve and inject Ar gas into the vacuum chamber to maintain the vacuum at 2 to 5 Pa, set the bias voltage in the range of -700V to -1000V, and perform glow ion etching on the surface of the substrate for 10 minutes Then turn off the Ar gas, feed nitrogen to maintain the vacuum at 0.1-0.5 Pa; use the contact method to directly ignite the cathode arc from the arc needle. In this example, the arc current is 150A, the pulse bias voltage is -80V, the duty cycle is 40%, and the time is 30min. Thus a Cr-N coating is obtaine...

Embodiment 3

[0037] This example illustrates the low interdiffusion and anti-high temperature oxidation multi-component coating for copper conductors prepared by multi-arc ion plating and its preparation method. First, install the chromium alloy target on the cathode water-cooled target sleeve. The chromium alloy target contains one or a combination of Al, Ni, Ag, Si, Fe, Ti, Zr, and its total content is 0-50% of the atomic ratio. Hang the copper piece in front of the target, close the door of the vacuum chamber, and pump air; the vacuum degree of the back of the chamber reaches 10 -3 At Pa level or lower, open the pressure valve and inject Ar gas into the vacuum chamber to maintain the vacuum at 2-5Pa, set the bias voltage in the range of -500V--700V, and perform glow ion etching on the surface of the substrate for 2 minutes Then close the Ar gas and use the contact method to ignite the cathode arc directly from the arc needle. In this example, the arc current is 200A, the pulse bias vol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com