Novel conductive rubber band and production method thereof

A manufacturing method and technology of conductive rubber bands, applied in the field of textile rubber bands, can solve the problems of insufficient tension, easy corrosion, and poor durability of conductive threads, and achieve the effects of simple production methods, good electrical conductivity, and good elastic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

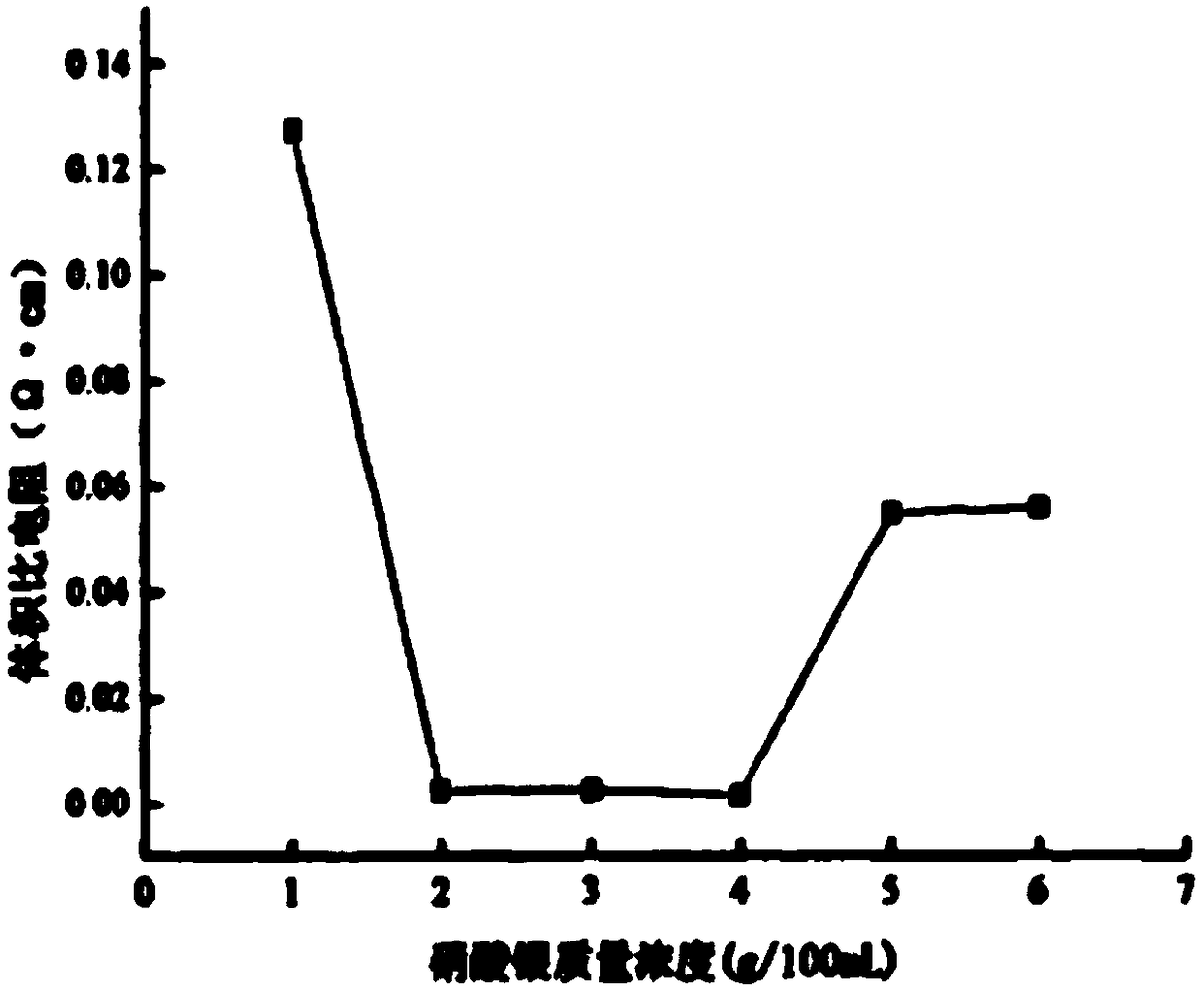

[0034] Such as figure 1 As shown, in Example 1, it is set that each 1L of silver plating solution includes: 20mL of ammonia water, 10g of glucose, the temperature of the silver plating solution is controlled at 30°C, the bath ratio is controlled at 1:100, and the soaking time is controlled at 30min. The relationship between the mass concentration of silver nitrate and the volume specific resistance of fiber filaments.

[0035] from figure 1 It can be seen that the volume specific resistance after silver nitrate treatment drops sharply, but when it reaches 40g / L, the volume specific resistance of the fiber reaches the minimum value, and when the silver nitrate is 10g / L, the volume specific resistance of the fiber reaches the maximum, indicating that The fiber has not been fully absorbed in the silver plating solution, and as the concentration of silver nitrate continues to increase, the silver adsorbed on the surface of the fiber increases sharply, and the fiber does not have ...

Embodiment 2

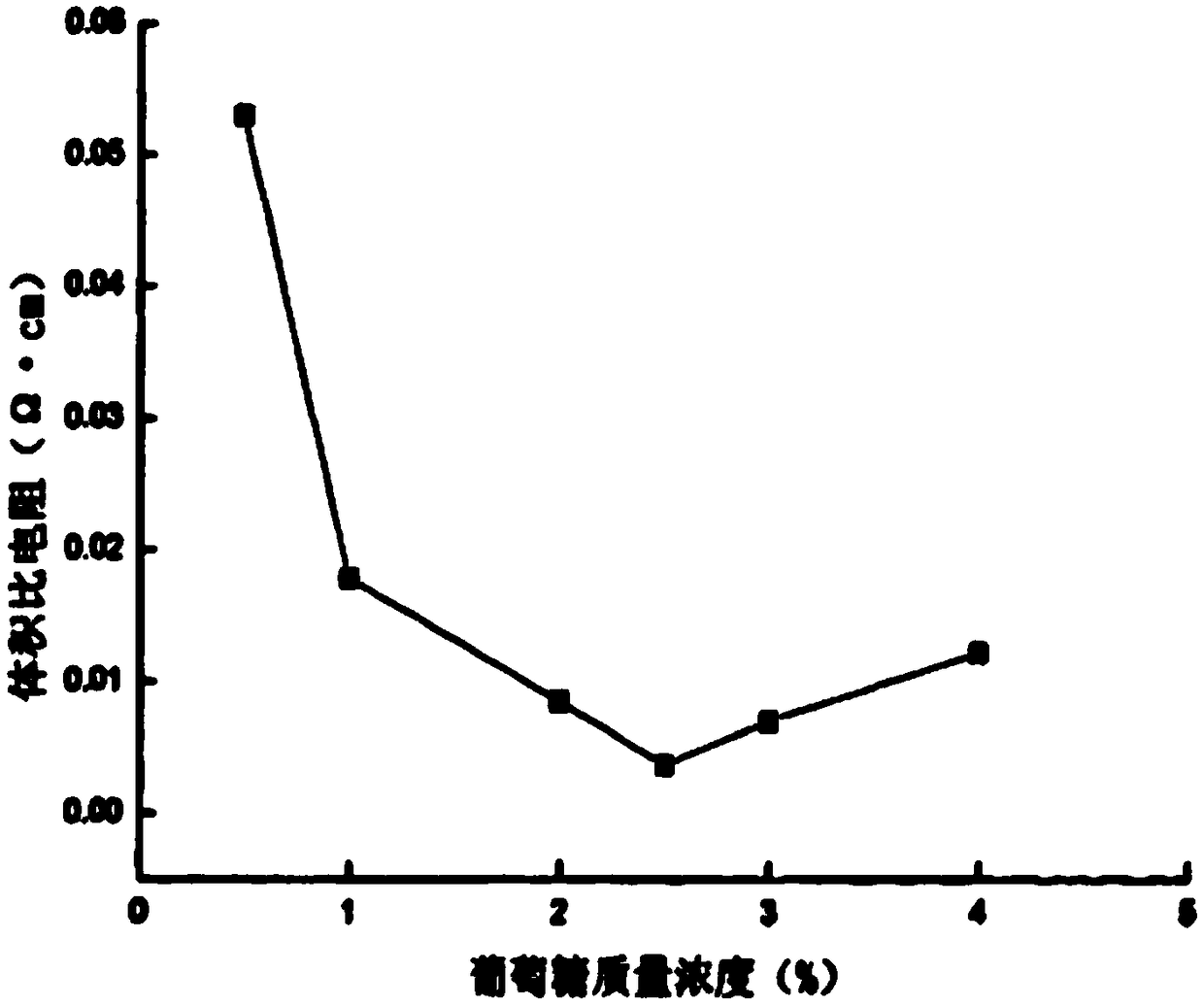

[0037] Such as figure 2 As shown, in Example 2, it is set that every 1L of the silver plating solution includes: the acid silver concentration is 20g, ammonia water 20mL, the temperature of the silver plating solution is controlled at 30°C, the bath ratio is controlled at 1:100, and the soaking time is controlled at 30min , the relationship between the mass concentration of glucose and the volume specific resistance of the filament at this time.

[0038] from figure 2 It can be seen from the figure that with the increase of glucose dosage, the volume specific resistance of the tissue decreases continuously. When the glucose concentration reaches 25g / L, the volume specific resistance reaches the minimum value. As the glucose dosage continues to increase, the volume specific resistance of the fiber increases instead. Large, this is because there is too much glucose, so that the silver-plated meter is quickly reduced to metallic silver, and the surface of the fiber filament ha...

Embodiment 3

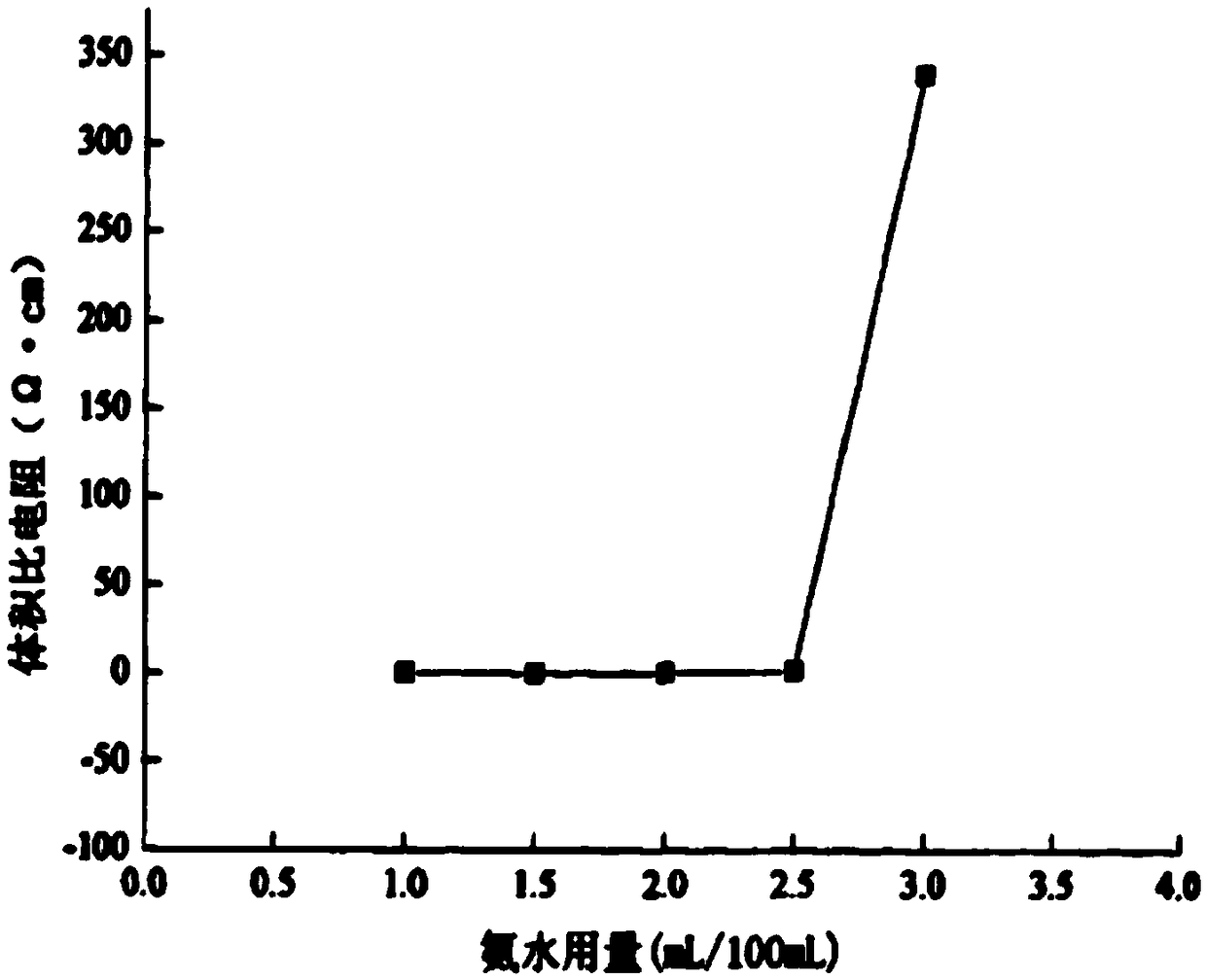

[0040] Such as image 3 As shown, in Example three, it is set to include in every 1L of silver plating solution: the acid silver concentration is 20g, the glucose quality is 10g / L, the silver plating solution temperature is controlled at 30°C, the bath ratio is controlled at 1:100, soaking The time is controlled at 30 minutes, and the relationship between the amount of ammonia water and the volume specific resistance of the fiber filament at this time.

[0041] from image 3 It can be seen that when the amount of ammonia water is small, the silver ions in the silver-plating solution do not completely react, and the fiber filaments do not have conductivity. When the amount of ammonia water reaches 10mL / L, the silver ions in the silver-plating solution can completely react. The solubility of ammonia water is 20mL / L, and the volume specific resistance of the fiber silk reaches the minimum value. If you continue to increase the ammonia water, the resistance will increase sharply....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com