Impurity-removed mud resource utilization method

A technology of resource utilization and phosphorus removal agent, applied in the field of hydrometallurgy, can solve the problems of high cost and low yield of removing impurity sludge, and achieve the effects of low consumption cost, low vanadium content and high vanadium leaching yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

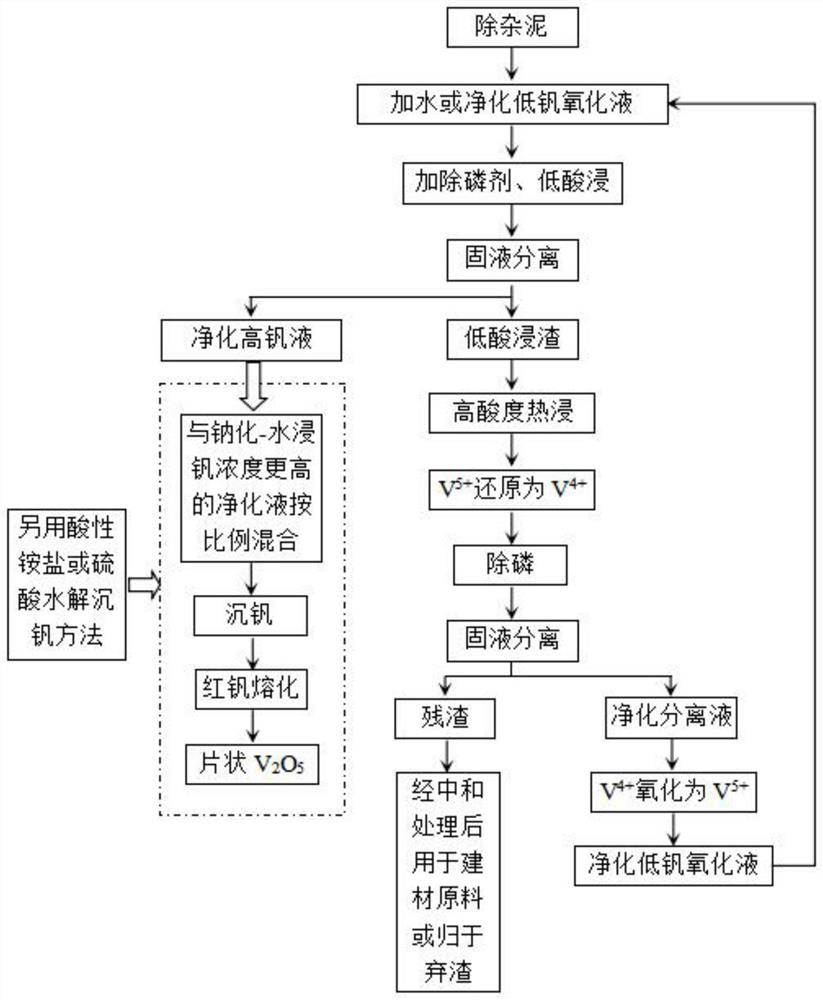

Image

Examples

Embodiment 1

[0050] The method for resource utilization of mud removal is characterized in that it comprises the following steps:

[0051] a. Mix 100g of impurity removal mud (V%=3.61%, P%=0.818%) and 300mL of water in a 500mL beaker, add 4.5g of iron sulfate under stirring, and then adjust its pH to 2.8-3.0, Stir again for 1.5h (stirring speed is 350r / min), solid-liquid separation obtains purified high-vanadium liquid and low-acid leaching residue;

[0052] b. Put the low-acid leaching residue obtained in step a into a 500ml beaker, add 80ml of water and 6ml of sulfuric acid and mix well, then heat to a slight boil for 12min to obtain a slurry;

[0053] c. Dilute to 150ml according to the slurry, add ferrous sulfate (FeSO 4 ·7H 2 (0) 5.0g stirred and dipped for 0.5h, then adjusted its pH with sodium carbonate solution (150g / L) to be 2.8-3.0, and then separated the solid and liquid after stirring for 1h to obtain the separated vanadium liquid and residue, and use pH=2.9±0.1 sulfuric acid...

Embodiment 2

[0057] The method for resource utilization of mud removal is characterized in that it comprises the following steps:

[0058] a. Mix 100 g of impurity-removing mud (V%=3.61%, P%=0.818%) and 323 mL of the purified low-vanadium oxidation solution obtained in Example 1 in a 500 mL beaker, and adjust its pH to 2.8-3.0 with concentrated sulfuric acid , then stirred for 2h (stirring speed is 350r / min), solid-liquid separation to obtain purified high vanadium liquid and low acid leaching residue;

[0059] b. Put the low-acid leaching residue obtained in step a into a 500ml beaker, add 80ml of water and 6ml of sulfuric acid and mix well, then place it in a water bath at 90°C and soak for 30min to obtain a slurry;

[0060] c. Dilute to 150ml according to the slurry, add 1.2g of sodium metabisulfite and stir for 40min, then adjust the pH to 2.8-3.0 with sodium carbonate solution (150g / L), and then stir for 1.5h to separate the solid and liquid to obtain the separated vanadium liquid and...

Embodiment 3

[0064] The method for resource utilization of mud removal is characterized in that it comprises the following steps:

[0065] a. After mixing 100 g of impurity removal mud (V%=3.89%, P%=1.67%) and the purified low-vanadium oxidation solution 333 mL obtained in Example 2 in a 500 mL beaker, add 8.5 g of iron sulfate under stirring, Then adjust its pH to be 2.8-3.0, then stir for 2h (stirring speed is 350r / min), solid-liquid separation obtains purified high vanadium liquid and low acid leaching residue;

[0066] b. Put the low-acid leaching residue obtained in step a into a 500ml beaker, add 90ml of water and 7ml of concentrated sulfuric acid and mix well, then heat to a slight boil for 12min to obtain a slurry;

[0067] c. Dilute to 150ml according to the slurry, add 1.4g of sodium sulfite and stir for 0.5h, then use sodium carbonate solution (150g / L) to adjust its pH to 2.8-3.0, and then stir for 1.5h to separate the solid and liquid to obtain the separated vanadium liquid and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com