Method for preparing briquette coal from coking wastewater and coke powder

A technology of coking waste water and coke powder, which is applied in the direction of solid fuel, petroleum industry, fuel, etc., can solve the problems of reducing the calorific value of coal briquettes, and achieve the effects of harmless treatment, increasing calorific value, and efficient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

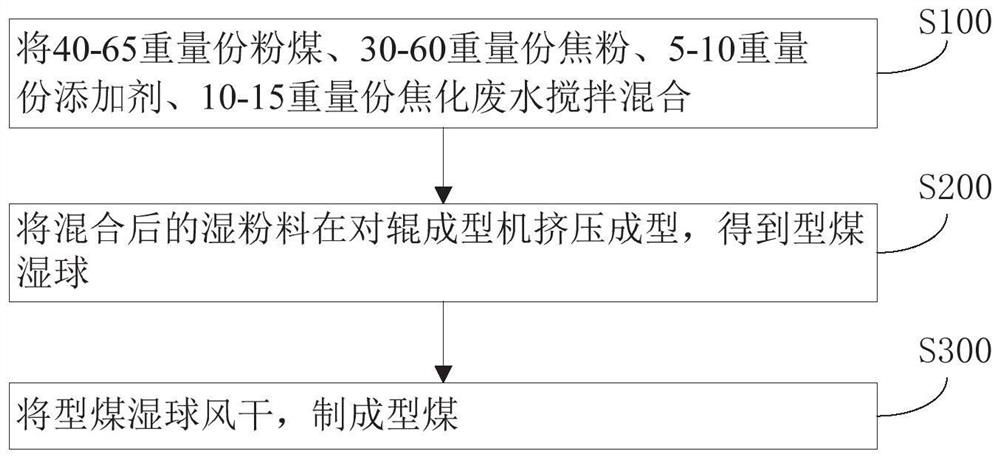

[0035] A kind of method that utilizes coking waste water and coke powder to prepare briquette disclosed in embodiment 1 of the present invention comprises the following steps:

[0036] Step S100, stirring and mixing 60 parts by weight of pulverized coal, 30 parts by weight of coke powder, 10 parts by weight of additives, and 15 parts by weight of coking wastewater;

[0037] Step S200, extruding the mixed wet powder in a double-roll molding machine to obtain a briquette wet ball;

[0038] Step S300, air-drying the wet ball of coal briquettes to make coal briquettes with water content below 5wt%.

[0039] The particle size of the above-mentioned pulverized coal is less than 2mm, the as-received total sulfur is 0.86%, and the as-received low calorific value is 22.43MJ / kg; the particle size of coke powder is less than 0.5mm, the as-received total sulfur is 0.97%, Base low fever is 28.96MJ / kg.

[0040] The additives include 25 parts by weight of carbide slag, 20 parts by weight o...

Embodiment 2

[0043] A kind of method that utilizes coking waste water and coke powder to prepare briquette disclosed in embodiment 2 of the present invention comprises the following steps:

[0044] Step S100, stirring and mixing 40 parts by weight of pulverized coal, 45 parts by weight of coke powder, 5 parts by weight of additives, and 10 parts by weight of coking wastewater;

[0045] Step S200, extruding the mixed wet powder in a double-roll molding machine to obtain a briquette wet ball;

[0046] Step S300, air-drying the wet ball of coal briquettes to make coal briquettes with water content below 5wt%.

[0047] The particle size of the above-mentioned pulverized coal is less than 2mm, the as-received total sulfur is 0.86%, and the as-received low calorific value is 22.43MJ / kg; the particle size of coke powder is less than 0.5mm, the as-received total sulfur is 0.97%, Base low fever is 28.96MJ / kg.

[0048] The additives include 20 parts by weight of carbide slag, 25 parts by weight of...

Embodiment 3

[0051] A kind of method that utilizes coking waste water and coke powder to prepare briquette disclosed in embodiment 3 of the present invention comprises the following steps:

[0052] Step S100, stirring and mixing 40 parts by weight of pulverized coal, 60 parts by weight of coke powder, 8 parts by weight of additives, and 12 parts by weight of coking wastewater;

[0053] Step S200, extruding the mixed wet powder in a double-roll molding machine to obtain a briquette wet ball;

[0054] Step S300, air-drying the wet ball of coal briquettes to make coal briquettes with water content below 5wt%.

[0055] The particle size of the above-mentioned pulverized coal is less than 2mm, the as-received total sulfur is 0.86%, and the as-received low calorific value is 22.43MJ / kg; the particle size of coke powder is less than 0.5mm, the as-received total sulfur is 0.97%, Base low fever is 28.96MJ / kg.

[0056] The additives include 30 parts by weight of carbide slag, 30 parts by weight of b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com