High durability concrete and preparation method thereof

A technology of durable concrete and machine-made sand, applied in the field of concrete, can solve the problems of affecting durability and poor durability, and achieve the effect of accelerating heat conduction, improving carbonization resistance, and enhancing toughening effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

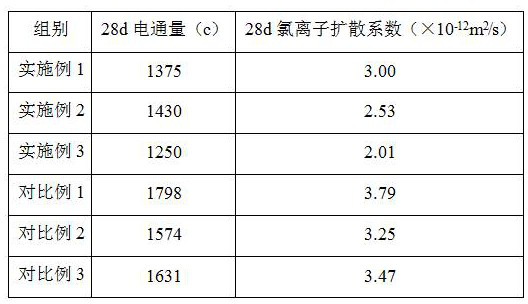

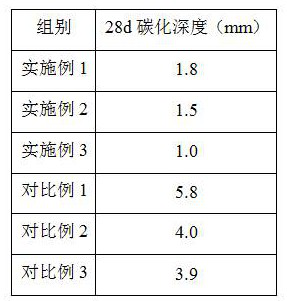

Embodiment 1

[0021] A high-durability concrete, the high-durability concrete comprises the following raw materials in parts by weight: 220 parts of cement, 50 parts of mineral powder, 50 parts of limestone grindstone powder, 940 parts of machine-made sand, 970 parts of limestone crushed stone, 9.5 parts of polycarboxylate Acid water reducing agent, 165 parts of water, 1 part of magnesium borate-carbon nanotube composite material, 0.3 part of diamond micropowder, 0.4 part of fiber material.

[0022] Wherein, the preparation method of the magnesium borate-carbon nanotube composite material includes: dissolving borax in water to prepare a borax solution with a mass fraction of 12%, dissolving carbon nanotubes and a dispersant in water to prepare a carbon nanotube with a mass fraction of 7% Nanotube solution, dissolve magnesium nitrate in water to prepare a magnesium nitrate solution with a mass fraction of 12%, add the carbon nanotube solution dropwise to the borax solution in a volume ratio o...

Embodiment 2

[0030] A high-durability concrete, the high-durability concrete comprises the following raw materials in parts by weight: 210 parts of cement, 60 parts of mineral powder, 50 parts of limestone grindstone powder, 950 parts of machine-made sand, 950 parts of limestone crushed stone, 10 parts of polycarboxylate Acid water reducing agent, 165 parts of water, 2 parts of magnesium borate-carbon nanotube composite material, 0.5 part of diamond micropowder, 0.7 part of fiber material.

[0031] Wherein, the preparation method of the magnesium borate-carbon nanotube composite material includes: dissolving borax in water to prepare a borax solution with a mass fraction of 14%, dissolving carbon nanotubes and a dispersant in water to prepare a carbon nanotube with a mass fraction of 11% Nanotube solution, dissolve magnesium nitrate in water to prepare a magnesium nitrate solution with a mass fraction of 14%, add the carbon nanotube solution dropwise to the borax solution in a volume ratio ...

Embodiment 3

[0039] A high-durability concrete, the high-durability concrete comprises the following raw materials in parts by weight: 200 parts of cement, 70 parts of mineral powder, 50 parts of limestone grindstone powder, 960 parts of machine-made sand, 950 parts of limestone crushed stone, 8.5 parts of polycarboxylate Acid water reducer, 165 parts of water, 1.5 parts of magnesium borate-carbon nanotube composite material, 0.4 part of diamond micropowder, 0.6 part of fiber material.

[0040] Wherein, the preparation method of the magnesium borate-carbon nanotube composite material includes: dissolving borax in water to prepare a borax solution with a mass fraction of 13%, dissolving carbon nanotubes and a dispersant in water to prepare a carbon nanotube with a mass fraction of 9% Nanotube solution, dissolve magnesium nitrate in water to prepare a magnesium nitrate solution with a mass fraction of 13%, add the carbon nanotube solution dropwise to the borax solution in a volume ratio of 1:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com