Antistatic halogen-free environment-friendly flame-retardant sheet moulding compound and preparation method thereof

A sheet molding compound and flame retardant technology, applied in the field of sheet molding compound, can solve the problems of comprehensive mechanical properties and surface quality decline of sheet molding compound, improve comprehensive mechanical properties, improve flame retardant properties, and ensure compactness. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

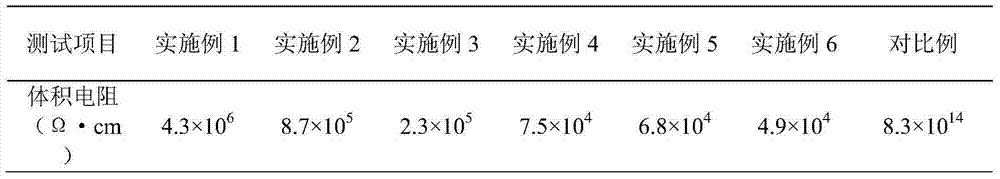

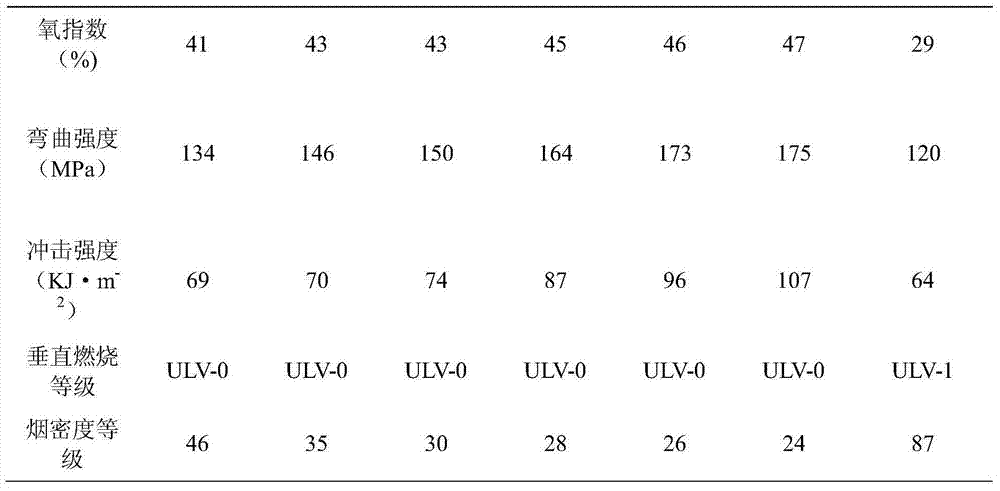

Embodiment 1

[0030] In the sheet molding compound of the present invention, its components are selected in parts by mass, 70 parts of unsaturated polyester resin, 30 parts of polystyrene slurry, 1 part of initiator, 2 parts of thickener, 0.04 part of polymerization inhibitor, 4 parts of molding agent, 60 parts of filler, 3 parts of antistatic agent, 60 parts of aluminum hydroxide, 10 parts of intumescent flame retardant, 2 parts of smoke suppressant, 5 parts of anti-shedding agent, 50 parts of glass fiber, 10 parts of stainless steel fiber Firstly, graphene and coupling agent are added into the ball milling tank, and a certain amount of absolute ethanol is added as the ball milling medium, the ball milling tank is closed and ball milled at a speed of 500 rpm for 3 hours, and then dried in an oven; Add the processed graphene, smoke suppressant, anti-shedding agent, initiator, polymerization inhibitor and mold release agent into the batching kettle and stir for 8 minutes at 500 rpm; filler ca...

Embodiment 2

[0032] The sheet molding compound of the present invention, its component by mass parts, selects 80 parts of unsaturated polyester resins, 40 parts of polystyrene slurry, 1.5 parts of initiators, 3 parts of thickeners, 0.1 parts of polymerization inhibitors, 6 parts of molding agent, 80 parts of filler, 5 parts of antistatic agent, 50 parts of aluminum hydroxide, 15 parts of intumescent flame retardant, 4 parts of smoke suppressant, 5 parts of anti-shedding agent, 50 parts of glass fiber, 30 parts of stainless steel fiber Firstly, graphene and coupling agent are added into the ball milling jar, and a certain amount of absolute ethanol is added as the ball milling medium, the ball milling jar is closed and ball milled at a speed of 600 rpm for 3.5 hours, and then dried in an oven; Add the processed graphene, smoke suppressant, anti-shedding agent, initiator, polymerization inhibitor and mold release agent into the batching kettle and stir for 10 minutes at 700 rpm; filler calciu...

Embodiment 3

[0034] The sheet molding compound of the present invention, its component by mass parts, selects 80 parts of unsaturated polyester resins, 50 parts of polystyrene slurry, 2 parts of initiators, 3 parts of thickeners, 0.1 parts of polymerization inhibitors, 7 parts of molding agent, 80 parts of filler, 7 parts of antistatic agent, 60 parts of aluminum hydroxide, 20 parts of intumescent flame retardant, 4 parts of smoke suppressant, 6 parts of anti-shedding agent, 40 parts of glass fiber, 40 parts of stainless steel fiber Firstly, graphene and coupling agent are added into the ball milling jar, and a certain amount of absolute ethanol is added as the ball milling medium, the ball milling jar is closed and ball milled at a speed of 600 rpm for 4 hours, and then dried in an oven; Add the treated graphene, smoke suppressant, anti-shedding agent, initiator, polymerization inhibitor and mold release agent into the batching kettle and stir for 15 minutes at 1200 rpm; Add the flame ret...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com