Water tank structure of cleaning vehicle

A technology for cleaning water and cleaning vehicles, applied in the field of sanitation cleaning vehicles, can solve the problems of uneven force on the tank body, the risk of water leakage of the tank body due to fatigue damage, and poor overall structural stability, so as to improve safety and reliability and reduce structural Fatigue damage risk, effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

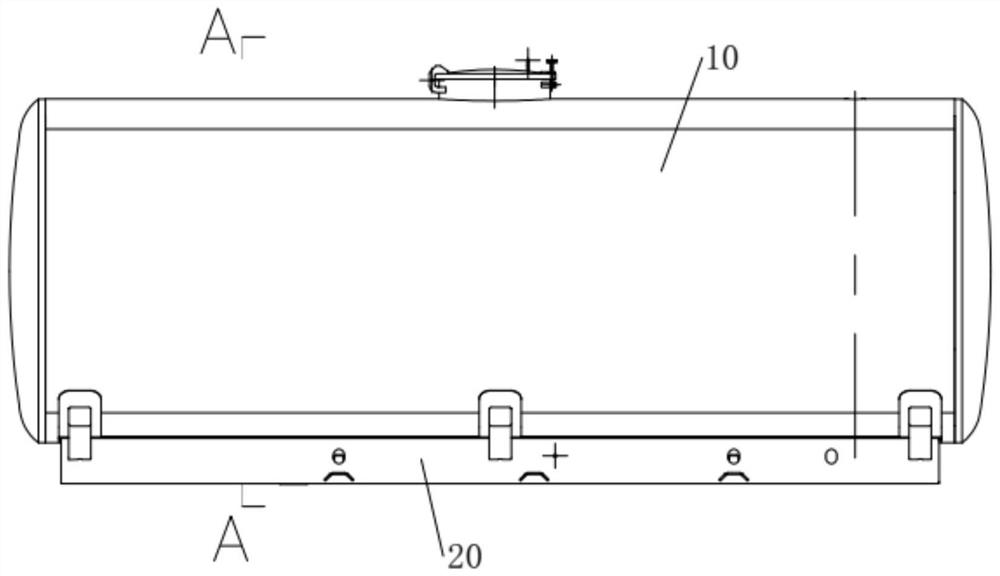

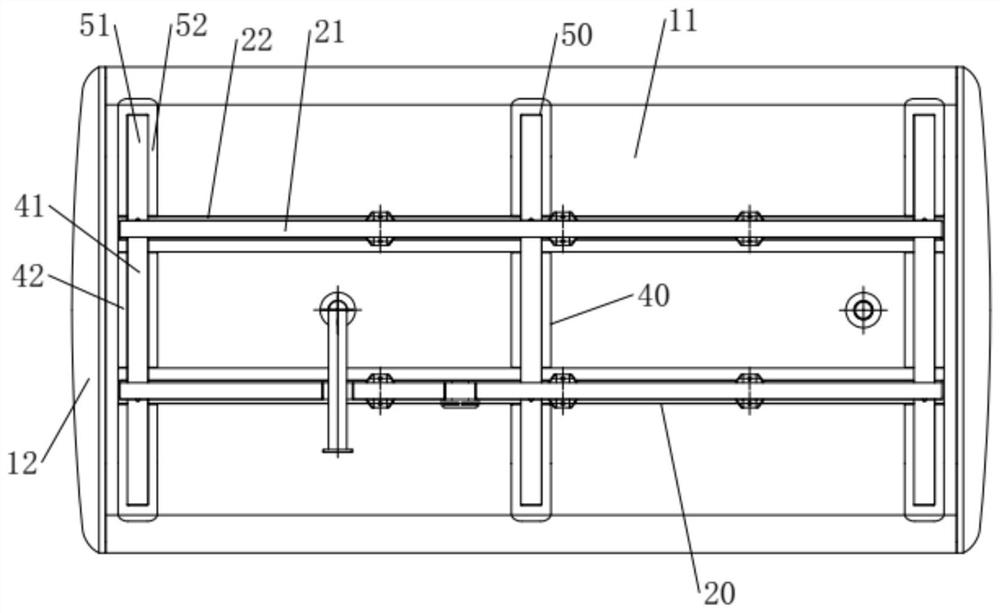

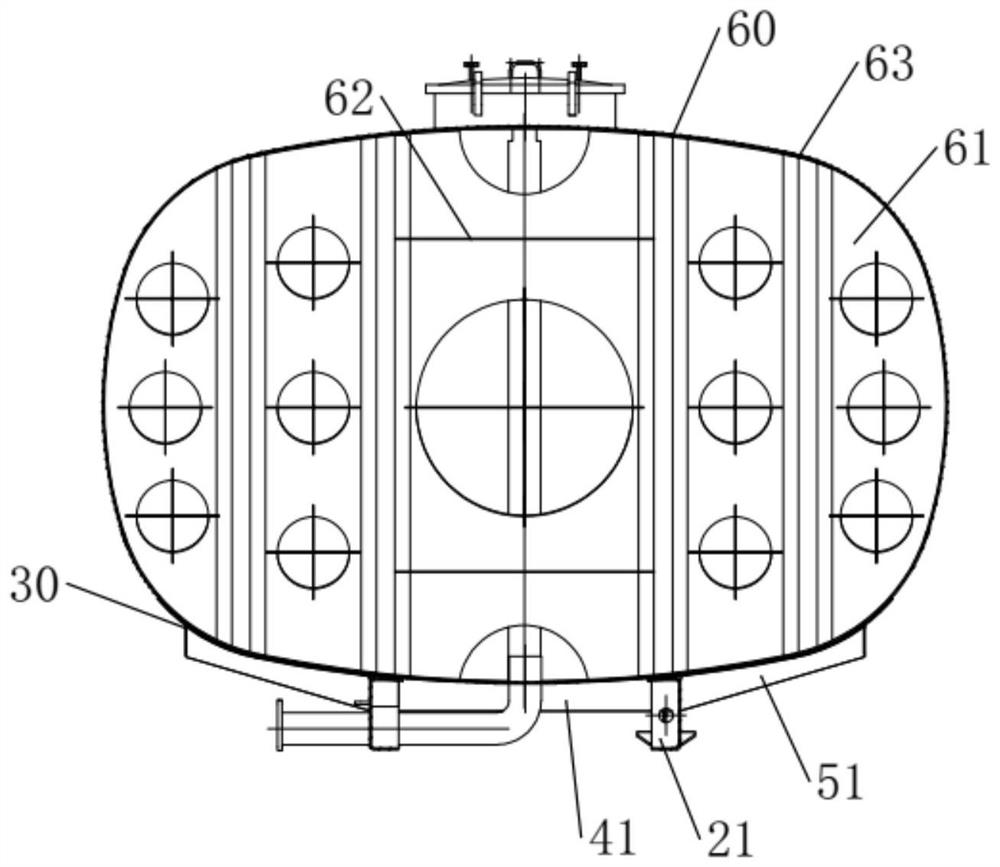

[0035] refer to figure 1 and figure 2 , The preferred embodiment of the present invention provides a water tank structure for cleaning vehicles, including: a supporting base frame for supporting and fixing, and a tank body 10 for containing cleaning water. The supporting chassis is arranged on the chassis along the length direction of the cleaning vehicle chassis, including longitudinal skeletons 20 and transverse skeletons arranged criss-cross along the length direction and width direction of the chassis, and the longitudinal skeletons 20 and the transverse skeletons are connected to form a concave and The concave containing section 30 for accommodating the position-limiting tank body 10 . The tank body 10 is welded and fixed in the concave containment area 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com