Novel rubber processing equipment

A processing equipment and rubber technology, applied in the field of new rubber processing equipment, can solve the problems of increased workload, low efficiency of grinding process, poor precision, etc., and achieve the effects of strong applicability, avoiding workload and cutting errors, and improving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

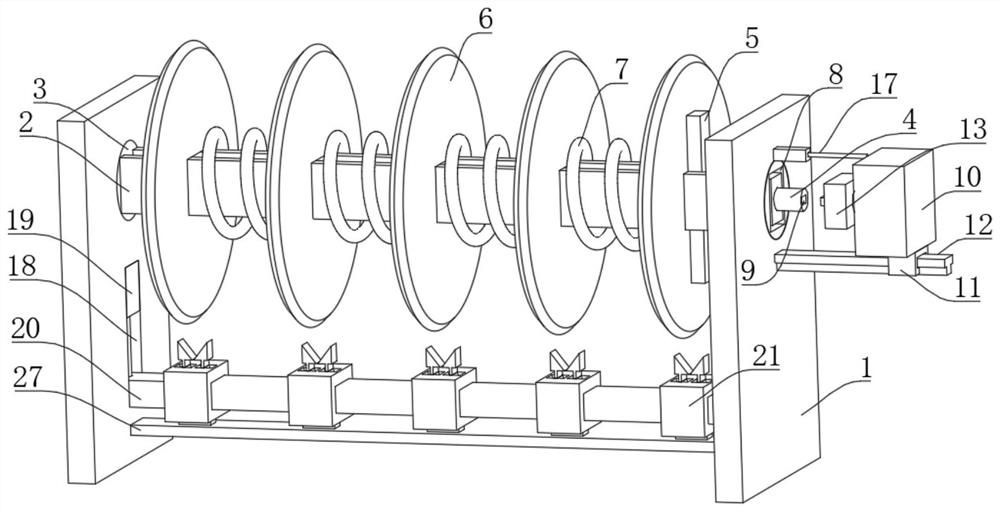

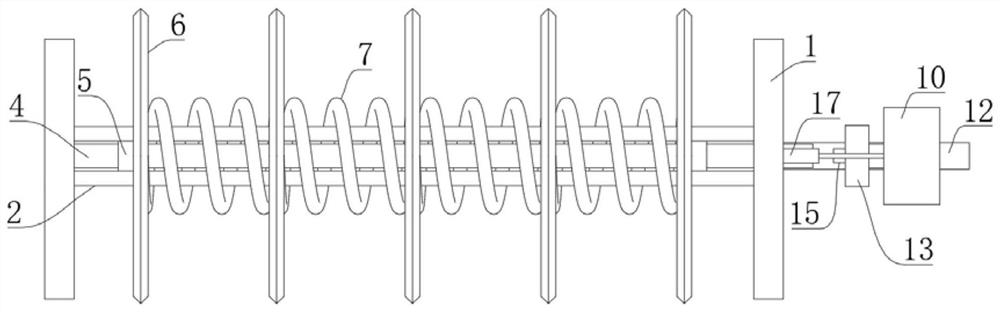

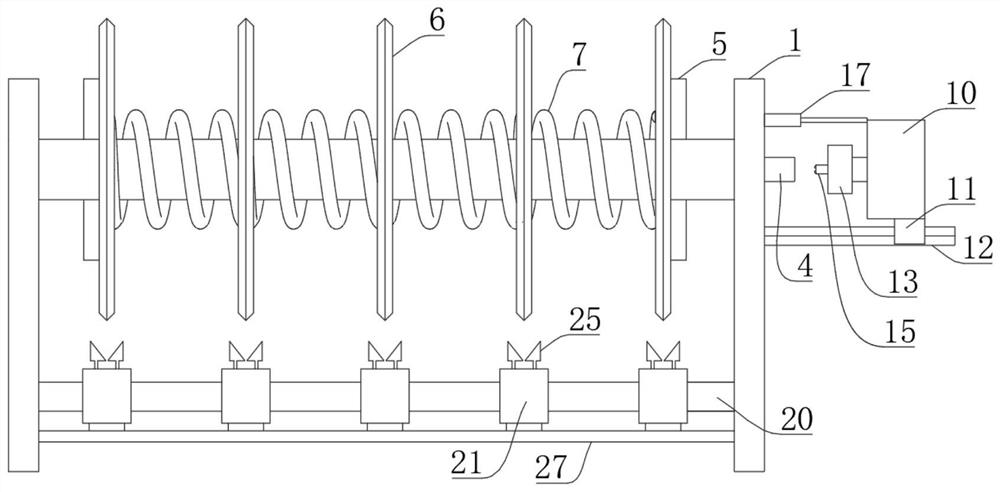

[0038] refer to Figure 1-8, a new type of rubber processing equipment, including two vertical boards 1, a long square frame 2 is arranged between the two vertical boards 1, indicating that the sides of the long square frame 2 are square, which is convenient for torque transmission, and the long square Both ends of the frame 2 are integrally formed with rotating disks 3, and the two rotating disks 3 are respectively connected in rotation with the vertical plate 1 located close to each other using bearings. The rotating disks 3 are set to facilitate rotation. Two-way threaded rod 4, the cross-sectional diameter of two-way threaded rod 4 is smaller than the distance between the inner walls on both sides of the elongated box 2, the two-way threaded rod 4 is in clearance fit with the elongated box 2, and the right end of the two-way threaded rod 4 runs through the elongated box 2 and is set , the vertical plate 1 on the right side is connected with the rotating disk 3 and the two-...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 lies in that the elastic constants of the plurality of first springs 7 are different.

[0052] The above-mentioned embodiment 1 is suitable for cutting equal-width rubber strips, but in a special scenario, when it is necessary to cut rubber strips of different widths at one time, embodiment 1 cannot be applied.

[0053] In order to apply to special scenarios, the first spring 7 with different elastic coefficients can be selected according to the needs. The yield strength of each first spring 7 is different, and the degree of compression under the influence of external force is also different. Under this principle, the cutting blade can be adjusted without equal width. .

Embodiment 3

[0055] The difference between this embodiment and Embodiment 1 is that the elastic device includes a shielding plate 28 coaxially embedded on the two cutting blades 6, and the opposite sides of the two shielding plates 28 are sealed and fixedly connected with a shielding cover 29. The plate 28 and the shielding cover 29 can prevent the magnetic field of the electromagnetic device 30 from affecting other structures, the influence of the electromagnetic device 30 on the cutting blade 6, and the influence between the electromagnetic device 30 and the electromagnetic device 30. The opposite sides of each shielding plate 28 are symmetrically fixed. There are electromagnetic means 30, two electromagnetic means 30 are arranged opposite to each other.

[0056] In this embodiment, the electromagnetic device 30 is used to replace the first spring 7. The advantage is that the loss of the spring will not occur. In addition, the electromagnetic intensity can be set according to the specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com