Washable antibacterial super-hydrophobic coating as well as preparation method and application thereof

A super-hydrophobic coating, hydrophobic nanotechnology, applied in coatings, antifouling/underwater coatings, devices for coating liquids on surfaces, etc. Impact performance and other issues, to achieve the effect of washable and flexible, good application prospects, and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention proposes a kind of preparation method of washable antibacterial superhydrophobic coating, comprises the following steps:

[0034] S1: Select the double-sided adhesive layer, weigh the hydrophobic nanoparticles according to the mass ratio of the adhesive layer to the hydrophobic nanoparticles (20-30): 1, place the hydrophobic nanoparticles in water, stir, let stand, and place them on the water surface A particle film is formed on it.

[0035] If the mass of hydrophobic nanoparticles is too small, a dense hydrophobic particle film cannot be formed on the water surface; if the mass is too large, they will accumulate on the water surface, resulting in waste of raw materials.

[0036] Preferably, the preparation process of the hydrophobic nanoparticles comprises:

[0037] S11: Weigh stearic acid, nanoparticles and organic solvent according to the mass ratio (0.08-0.16): 1:30, add stearic acid and nanoparticles to the organic solvent, and heat to underg...

Embodiment 1

[0058] The present embodiment provides a kind of preparation method of washable antibacterial superhydrophobic coating, such as figure 1 shown, including the following steps:

[0059] S1: Put filter paper in the Buchner funnel, then install the funnel in a conical flask with a vent; close the vent, pour 40°C water into the funnel, with a height of about 4cm; weigh 0.8g of hydrophobic oxidation Zinc particles, and the hydrophobic zinc oxide particles are placed on the water surface, stirred for a while with a glass rod, the hydrophobic zinc oxide particles will spread evenly on the water surface to form a tight particle film;

[0060] S2: Cut the "3M" VHB acrylic foam tape into sections, paste it on the glass substrate, and then put it into the water slightly vertically from the side of the funnel, and the side with the tape layer is slightly facing the water surface;

[0061] S3: Turn the substrate to a horizontal state and lift it up slowly, and the particle film is attached...

Embodiment 2

[0071] This example provides a method for preparing a washable antibacterial superhydrophobic coating. Compared with Example 1, in this example, the substrate is not used in step S2, and the "3M" VHB acrylic foam tape is directly used. After the preparation is completed Attach the superhydrophobic coating on the syringe barrel, and the other steps are the same as in Example 1.

[0072] The superhydrophobic coating that present embodiment prepares is characterized:

[0073] The average static contact angle of the superhydrophobic coating prepared in this example is 155.3°, the measured rolling angle is 1°, and the antibacterial rate can reach 99%.

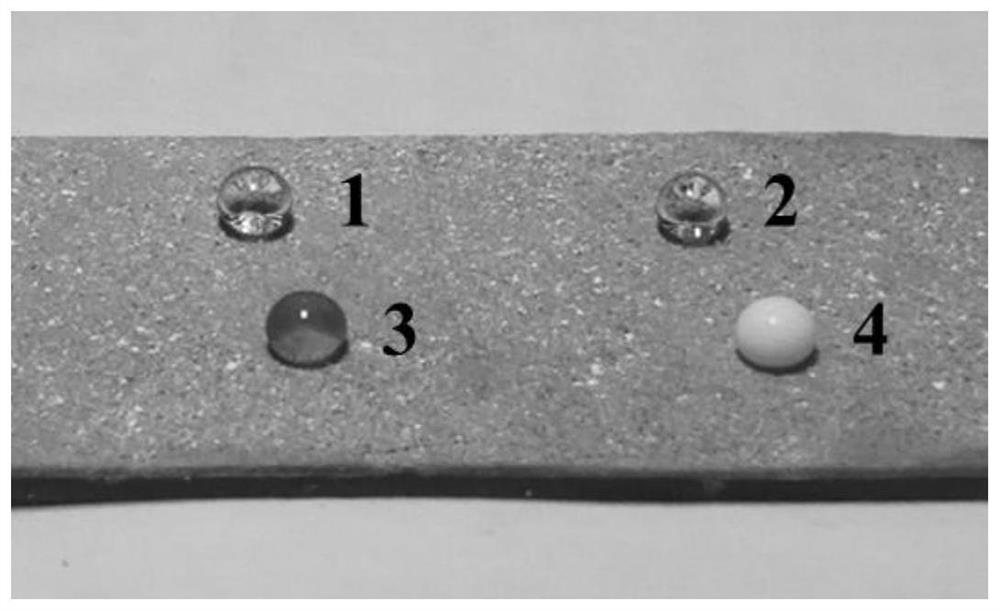

[0074] Image 6 It is an optical photograph of the superhydrophobic coating made in this embodiment. It can be seen from the figure that the preparation method of the present invention can be used on adhesive tapes to make super-hydrophobic functional adhesive tapes and realize technological transformation.

[0075] Figure 7 It...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com