Intelligent green tea fixation method

A green tea green tea technology, applied in tea treatment before extraction, etc., can solve the problems of unfavorable high-quality green tea production, energy waste, uneven green tea removal, etc., and achieve the effects of improving heat exchange efficiency, improving green removal efficiency, and improving heat utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

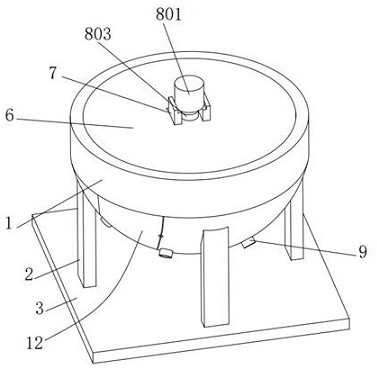

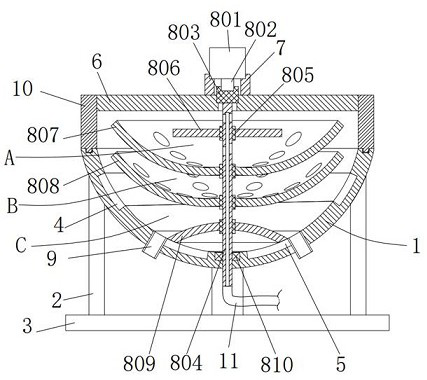

[0042] Example 1, see Figure 1-Figure 4 ,

[0043] A kind of green tea intelligent deenzyming method, comprises the following steps,

[0044] Step 1. Put the tea leaves to be finished into green tea finishing processing equipment;

[0045] Step 2. Connect the steam into the green tea fixation processing equipment, and make the steam entering the green tea fixation processing equipment pass through the tea leaves from top to bottom, and the temperature of the steam is 90-200°C;

[0046] Step 3: After the green tea leaves are finished in step 2, the tea leaves are discharged from the green tea green tea processing equipment.

[0047] The tea leaves are placed in the green-fixing tank body 1 of the green-fixing device, and the steam generated by the steam generating device enters the green-killing tank body 1 through the steam inlet pipe 11. Due to the existence of the stirring mechanism 8, the tea leaves are first stirred by the stirring device to improve On the other hand, ...

Embodiment 2

[0069] A green tea fixing method, using the green tea fixing processing equipment of the above-mentioned embodiment 1 to finish green tea, comprising the following steps: first place the tea leaves inside the second stirring plate 807 and the third stirring plate 808, and then heat the first The plate 4 and the second heating plate 5 are energized, and then the motor 801 is started, and the motor shaft 802 of the motor 801 makes a circular motion, and the transmission shaft 804 is driven by a coupling 803 to make a circular motion, so that the first stirring plate 806 and the second stirring plate 807 , the third stirring plate 808 and the bottom stirring plate 809 do circular motion, and start the steam generating device, and the first heating plate 4 and the second heating plate 5 are energized with the external power supply, and the first heating plate 4 and the second heating plate 5 are energized. Heating the inner space of the fixing tank body 1, conveying high-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com