A printed circuit board wet chemical processing equipment

A board wet chemistry and printed circuit technology, which is applied in the field of printed circuit board processing, can solve the problems of inconvenient circulation operation, inconvenient contact of the processing liquid with the circuit board, inconvenient rapid treatment of bubbles and effusion, etc., to reduce labor costs The effect of reducing the cost, reducing the time spent, and reducing the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

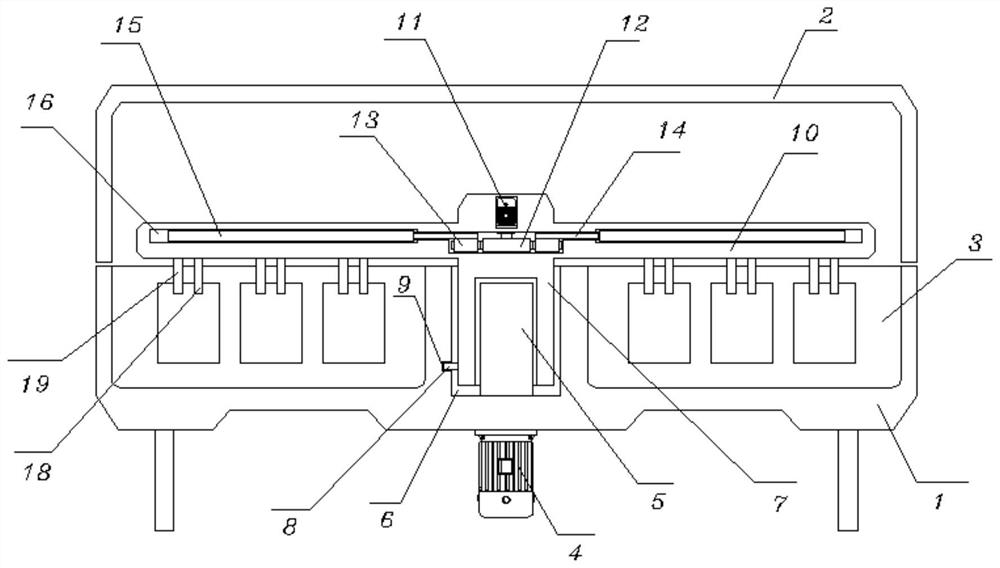

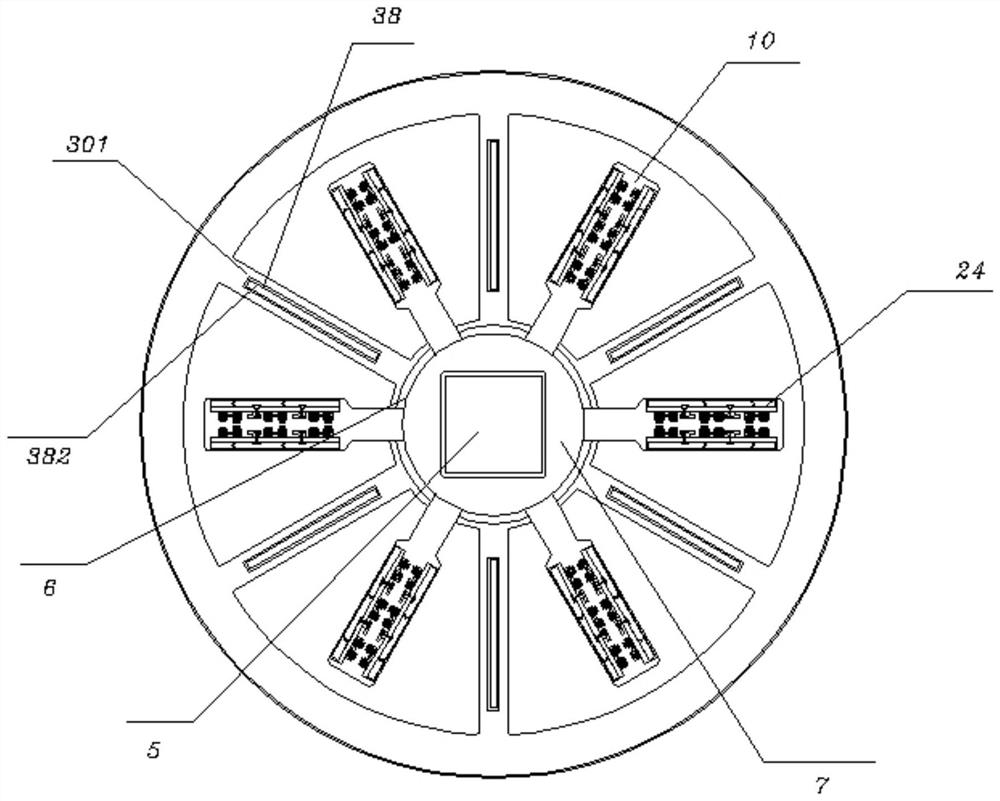

[0038] see Figure 1-3 , including a rack 1, a top cover 2 is installed on the top of the rack 1, a processing chamber 3 is opened on the upper end face of the rack 1, and a partition plate 301 is arranged between the processing chambers 3; it also includes: a first motor 4 , the first motor 4 is fixed on the bottom of the frame 1, and the output end of the first motor 4 is connected with a guide post 5, and the guide post 5 is located in the movable slot 6, and the movable slot 6 is opened in the middle of the top of the frame 1, A movable column 7 is sleeved on the guide column 5, and a guide rod 8 is fixed on the outer side of the movable column 7, and the guide rod 8 is located in the guide groove 9, and the guide groove 9 is opened on the inner wall of the movable groove 6. The top is located above the rack 1, and the side of the movable column 7 is fixed with a mounting plate 10, the inside of the top of the movable column 7 is embedded with a second motor 11, and the ou...

Embodiment 2

[0040] see Figure 1-2 , 4-6 and Figure 9 , the replacement slot 17, the replacement slot 17 is opened at the bottom of the mounting plate 10, and the replacement slot 17 is fitted with the first plywood 18 and the second plywood 19, the first plywood 18 and the second plywood 18 with a "T"-shaped structure on the front. One end of the clamping plate 19 is located below the mounting plate 10, and the inner sides of the bottoms of the first clamping plate 18 and the second clamping plate 19 are connected with a clamping piece 21 through the fixing spring 20, and the sides of the first clamping plate 18 and the second clamping plate 19 are replaced with each other. Magnetic sheets 22 are fixed at the corresponding positions of the inner wall of the groove 17, and an inner groove 23 is opened at the bottom edge of the mounting plate 10, and a mounting bar 24 with a "T"-shaped structure on the front side is fitted and placed in the inner groove 23, and the adjustment plate 15 A ...

Embodiment 3

[0042] see Figure 1-3 and Figure 7-8, the collection tank 38, the collection tank 38 is opened on the top of the partition plate 301, and the collection bucket 39 is fixed on the inner wall of the collection tank 38, and the bottom of the collection bucket 39 is connected with a gas collecting pipe 40, and one end of the gas collecting pipe 40 is connected through There is a gas collecting ring 41, the top of the gas collecting ring 41 is connected to the output end of the second air pump 42, and the second air pump 42 is fixed at the bottom position of the frame 1, and a sealing plate 382 is connected in the collecting groove 38 through a support spring 381 , and the bottom of the collection tank 38 is fixed with a pressure sensor 383, and the top of the sealing plate 382 is located above the partition plate 301, the top of the sealing plate 382 is designed in an isosceles trapezoid structure, and the side of the top of the sealing plate 382 is connected to the collection t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com