Battery pack impact test system

An impact test and battery pack technology, applied in the field of battery packs, can solve the problems of high acceleration energy, flammability and explosion, and pure battery packs without substantial protection, so as to improve efficiency and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

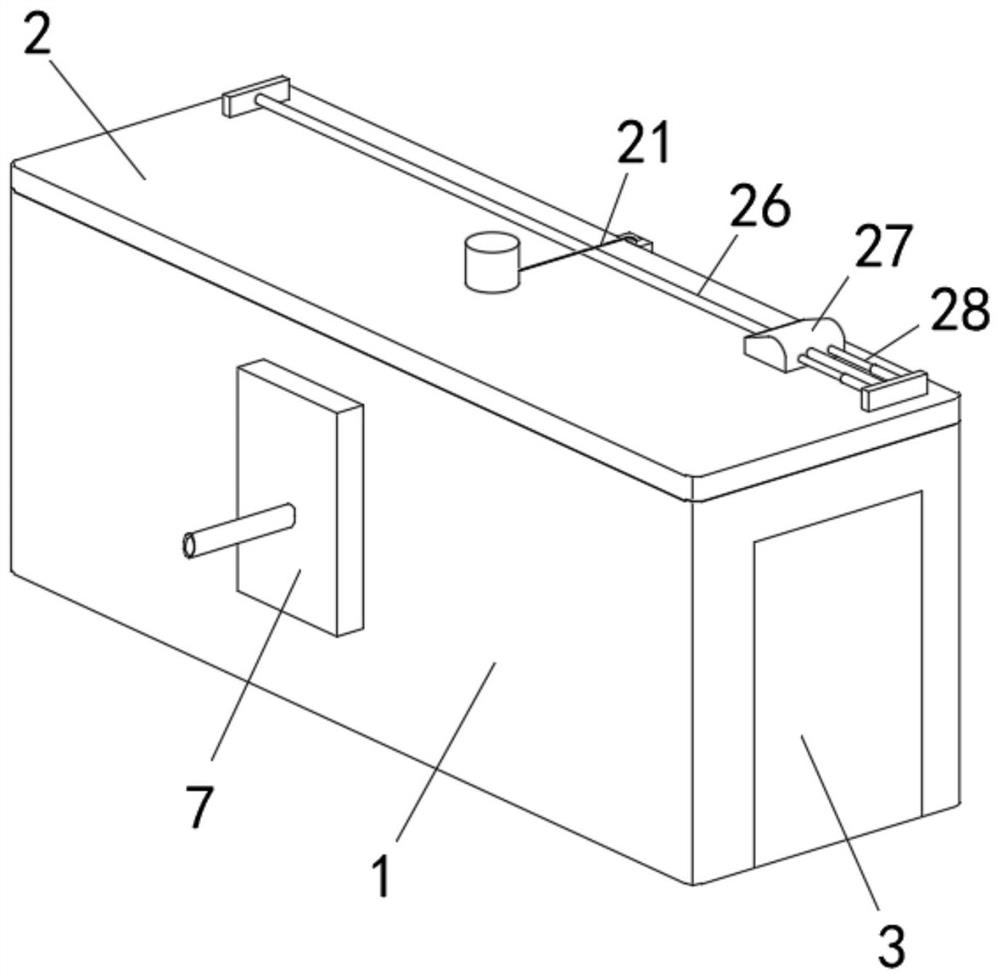

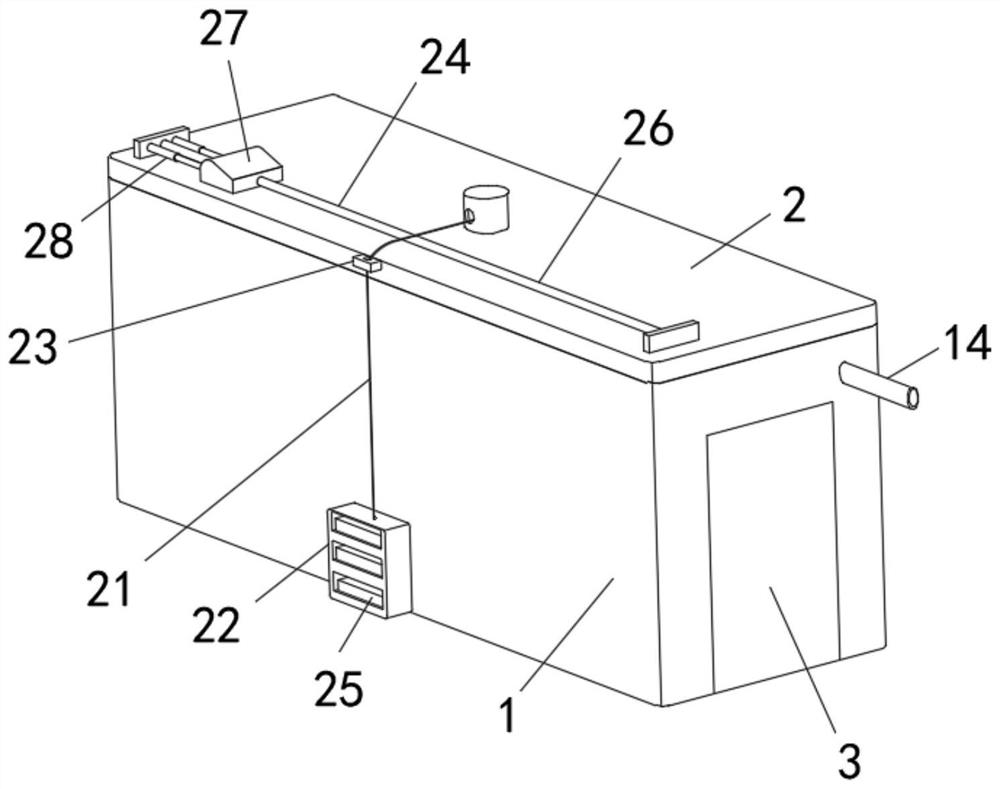

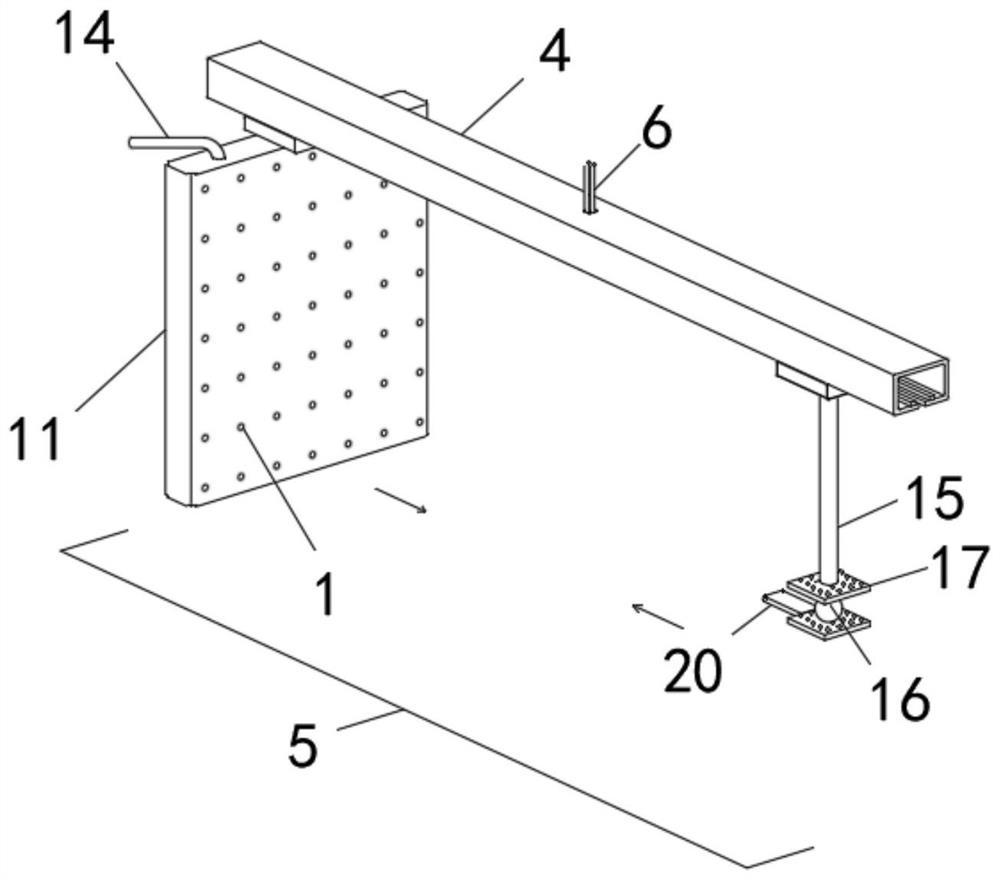

[0034] like Figure 1-3 As shown, a battery pack impact test system includes an enclosure 1 and a top cover 2. The enclosure 1 is transparent up and down, made of aluminum alloy, and the periphery is fixedly connected with a plurality of connecting corner pieces, mainly used for It is fixed on the ground and at the same time ensures a certain degree of airtightness at the bottom. The enclosure 1 is fixed on the ground but can also be moved for movement and shifting. There are movable opening and closing doors 3 on both sides for personnel The entrance and exit of the enclosure 1 is long and narrow, and the opening and closing doors 3 are set on the two ends of the long and narrow enclosure 1, respectively corresponding to the equipment installation or entry and exit of the impact unit and the test unit. The opening and closing door 3 is directly arranged on the enclosure 1 and has a sealing The top cover 2 is covered on the enclosure 1 and sealed to form a stable sealed enviro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com