Heading machine based on visual positioning technology

A positioning technology and technology for roadheaders, which are applied in the field of roadheaders based on visual positioning technology, can solve problems such as inability to apply small-scale coal roadheading operations, inconvenient adjustment of coal roadway driving directions, and inability to effectively remote real-time monitoring, etc. Stable and regular, the top is firm, and the effect of easy post-construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

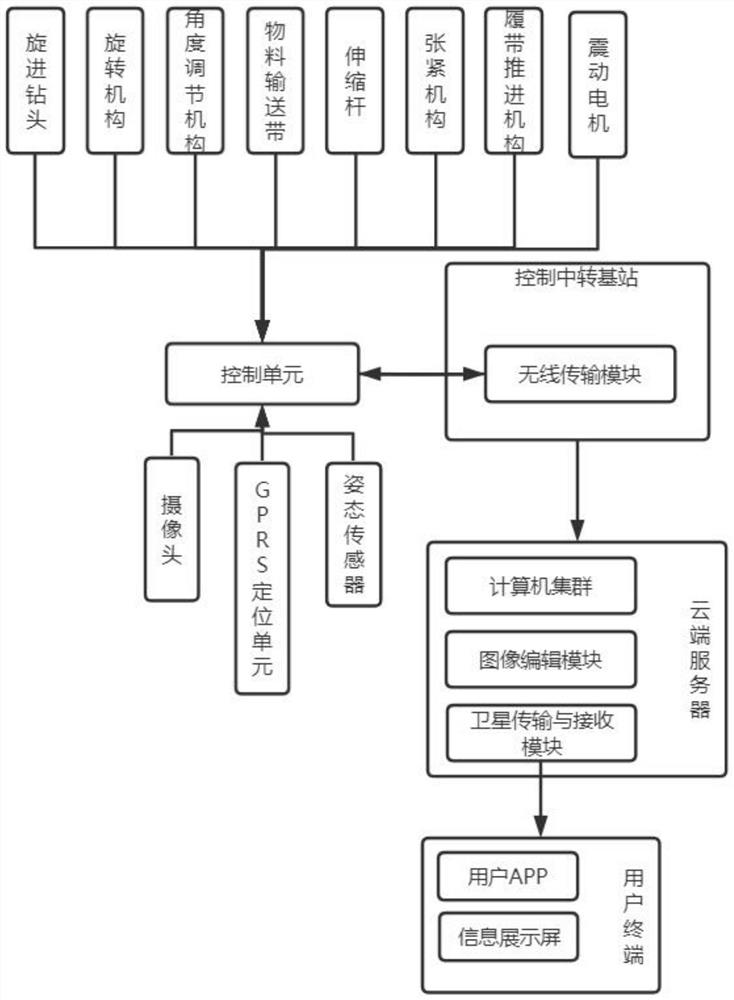

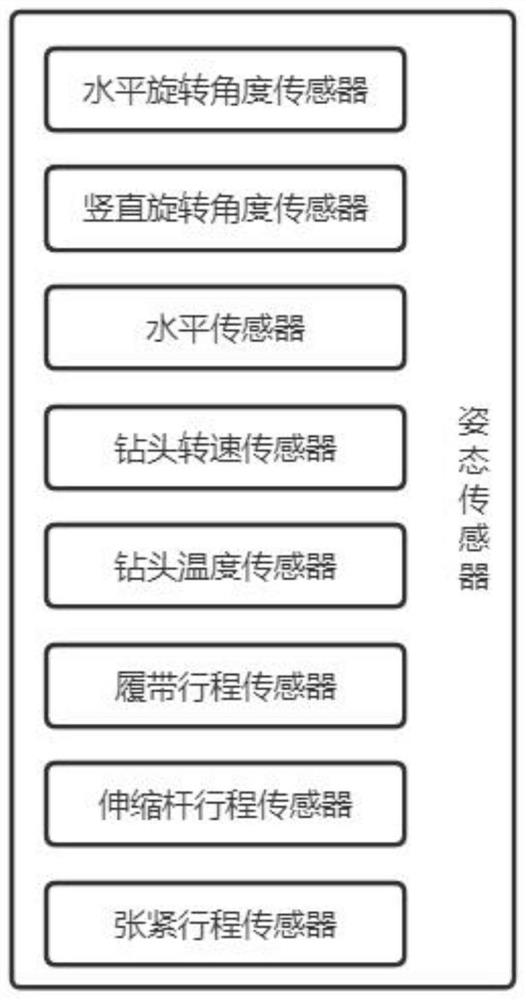

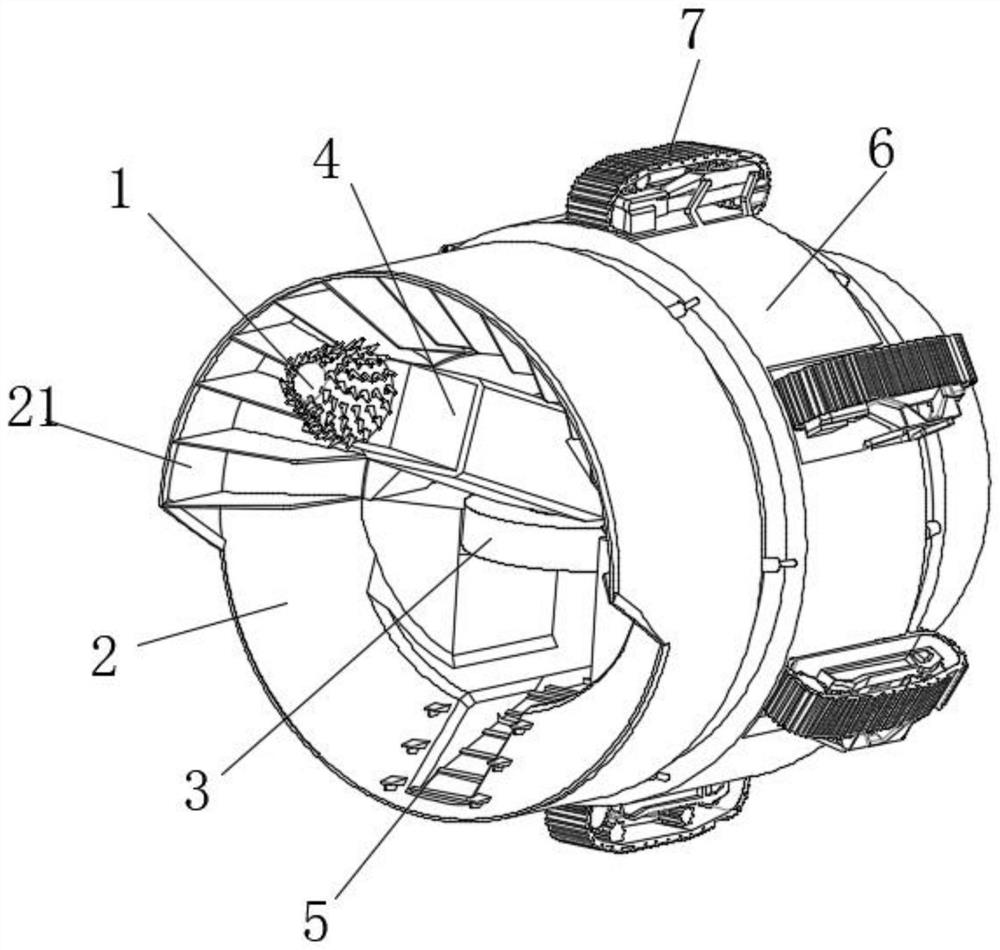

[0040] see Figure 1-10 , a roadheader based on visual positioning technology, including a cylindrical casing 2, a screw-in drill bit 1 and a control transfer base station, a rotating mechanism 3 is fixed inside the cylindrical casing 2, and an angle adjustment mechanism is fixed at the output end of the rotating mechanism 3 4. The screw-in drill bit 1 is fixed at the output end of the angle adjustment mechanism 4, the inner bottom of the cylindrical casing 2 is provided with a material conveyor belt 5, and the outer wall of the cylindrical casing 2 is provided with a spherical seat 23, which is connected to the rotating There is an annular support 6, the inner wall of the annular support 6 is provided with a ball groove 61 matching the spherical seat 23, and a plurality of telescopic rods 8 are arranged between both sides of the annular support 6 and the outer wall of the cylindrical casing 2, and a plurality of telescopic rods 8 are arranged. The rods 8 are equiangularly arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com