High-efficiency low-temperature phase-change cold storage agent and preparation method thereof

A technology of low-temperature phase change and cold storage agent, which is applied in the direction of chemical instruments and methods, mixers, heat exchange materials, etc., can solve the problems of supercooling, large latent heat of phase change, phase separation, etc., and achieve uniform cold source release and cold storage Good performance, not easy to leak effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

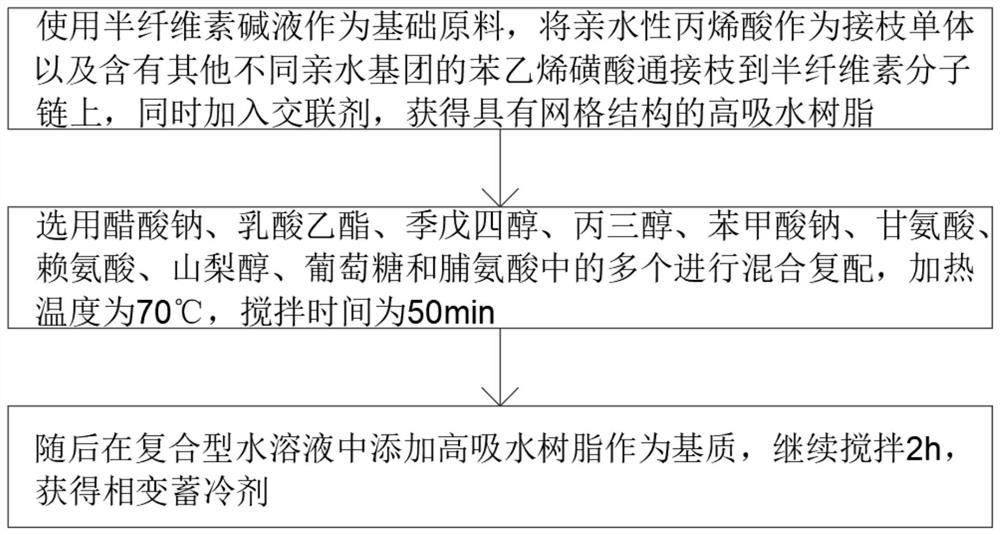

[0032] A high-efficiency low-temperature phase-change cold storage agent and its preparation method, the low-temperature phase-change cold storage agent includes a superabsorbent resin, a composite energy storage agent and pure water, and the superabsorbent resin includes hemicellulose lye, acrylic acid and styrene Sulfonic acid, the composite energy storage agent includes sodium acetate, ethyl lactate, pentaerythritol, glycerol, sodium benzoate, glycine, lysine, sorbitol, glucose and proline;

[0033] The parts by weight of the components of the superabsorbent resin are as follows: 40 parts of hemicellulose lye, 25 parts of acrylic acid and 6 parts of styrenesulfonic acid, and the mass percentages of the components of the composite energy storage agent are as follows: acetic acid Sodium 0.5%, Ethyl Lactate 1.5%, Pentaerythritol 0.5%, Glycerol 1%, Sodium Benzoate 0.5%, Glycine 1%, Lysine 0.5%, Sorbitol 0.5%, Glucose 0.5%, Proline 0.5% and The balance of pure water.

[0034] A...

Embodiment 2

[0048] A high-efficiency low-temperature phase-change cold storage agent and its preparation method. The low-temperature phase-change cold storage agent includes a superabsorbent resin, a composite energy storage agent, and purified water. The superabsorbent resin includes hemicellulose lye, acrylic acid, and styrenesulfonic acid. Type energy storage agents include ethyl lactate, pentaerythritol, glycerol and glycine;

[0049] The parts by weight of the components of the superabsorbent resin are as follows: 40 parts of hemicellulose lye, 25 parts of acrylic acid and 6 parts of styrenesulfonic acid, and the mass percentages of the components of the composite energy storage agent are as follows: 3% of ethyl lactate , pentaerythritol 1%, glycerol 1.5%, glycine 1%, and the balance of purified water.

[0050] A preparation method for a high-efficiency low-temperature phase-change cold storage agent, comprising the steps of:

[0051] Step 1. Use hemicellulose lye as the basic raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com