Ceramic building block and preparation method thereof

A technology of ceramics and blocks, which is applied in the field of ceramic blocks and its preparation, can solve the problems of environmental pollution, production cost and service performance without obvious changes, and achieve high early strength, excellent durability and high service strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

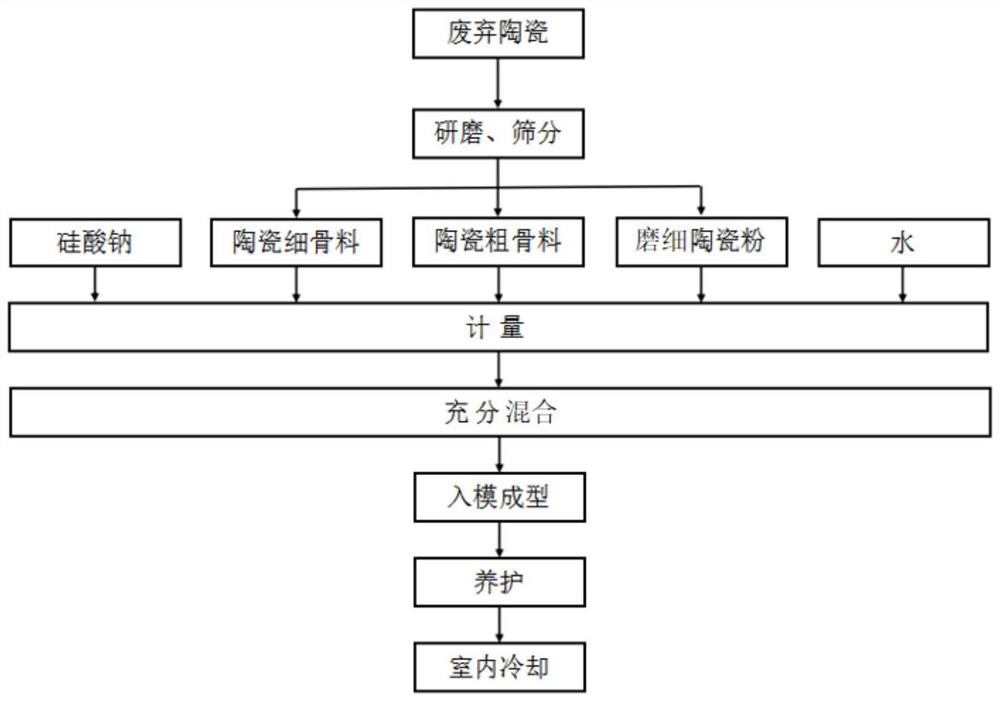

Method used

Image

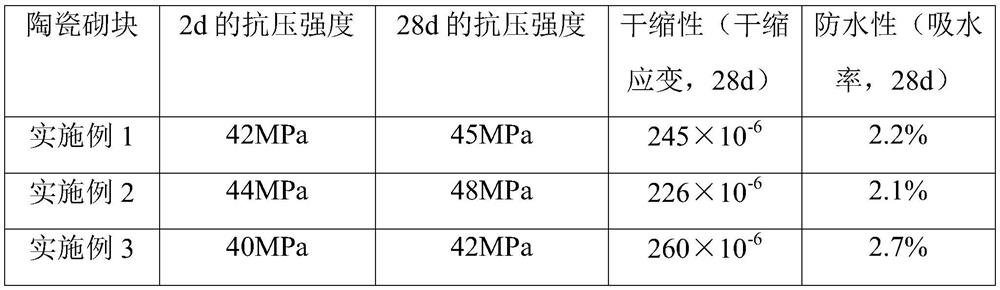

Examples

Embodiment 1

[0026] A ceramic block, comprising the following components in parts by mass:

[0027] 45 parts of ceramic coarse aggregate, 45 parts of ceramic fine aggregate, 20 parts of ground ceramic powder, 20 parts of sodium silicate and 8 parts of water;

[0028] The particle size of the ceramic coarse aggregate is 5 mm-10 mm, the particle size of the ceramic fine aggregate is 0.075 mm-5 mm, and the particle size of the ground ceramic powder is 10 μm-60 μm.

[0029] The above-mentioned ceramic coarse aggregate, ceramic fine aggregate and finely ground ceramic powder are all obtained from waste ceramics by crushing and sieving in a crusher, and their composition includes: SiO 2 63%, Al 2 o 3 22%, CaO3.6%, Na 2 O1.8%, K 2 O2.0%.

[0030] The preparation method of the above-mentioned ceramic block is as follows: after mixing the components of the ceramic block according to the above-mentioned mass fractions, pour it into a mold, maintain it at a temperature of 80°C and a pressure of...

Embodiment 2

[0033] A ceramic block, comprising the following components in parts by mass:

[0034] 64 parts of ceramic coarse aggregate, 53 parts of ceramic fine aggregate, 23 parts of ground ceramic powder, 22 parts of sodium silicate and 10 parts of water;

[0035] The particle size of the ceramic coarse aggregate is 5 mm-10 mm, the particle size of the ceramic fine aggregate is 0.075 mm-5 mm, and the particle size of the ground ceramic powder is 10 μm-60 μm.

[0036] The above-mentioned ceramic coarse aggregate, ceramic fine aggregate and finely ground ceramic powder are all obtained from waste ceramics by crushing and sieving in a crusher, and their composition includes: SiO 2 64%, Al 2 o 3 22%, CaO3.4%, Na 2 O1.9%, K 2 O1.8%.

[0037] The preparation method of the above-mentioned ceramic block is as follows: after mixing the components of the ceramic block according to the above-mentioned mass fractions, pour it into a mold, maintain it at a temperature of 85°C and a pressure of...

Embodiment 3

[0039] A ceramic block, comprising the following components in parts by mass:

[0040] 65 parts of ceramic coarse aggregate, 58 parts of ceramic fine aggregate, 25 parts of ground ceramic powder, 25 parts of sodium silicate and 12 parts of water;

[0041] The particle size of the ceramic coarse aggregate is 5 mm-10 mm, the particle size of the ceramic fine aggregate is 0.075 mm-5 mm, and the particle size of the ground ceramic powder is 10 μm-60 μm.

[0042] The above-mentioned ceramic coarse aggregate, ceramic fine aggregate and finely ground ceramic powder are all obtained from waste ceramics by crushing and sieving in a crusher, and their composition includes: SiO 2 64%, Al 2 o 3 20%, CaO1.7%, Na 2 O1.9%, K 2 O1.8%.

[0043] The preparation method of the above-mentioned ceramic block is as follows: after mixing the components of the ceramic block according to the above-mentioned mass fractions, pour it into a mold, maintain it at a temperature of 90°C and a pressure of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com