Novel pneumatic suction cup type tracked robot applied to cabin cargo transfer

A crawler robot and sucker-type technology, applied in the direction of conveyor objects, transportation and packaging, loading/unloading, etc., can solve the problems of low cargo transfer efficiency, personnel safety impact, and large personnel demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical solutions and advantages of the present invention more clear, the technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings in the embodiments of the present invention:

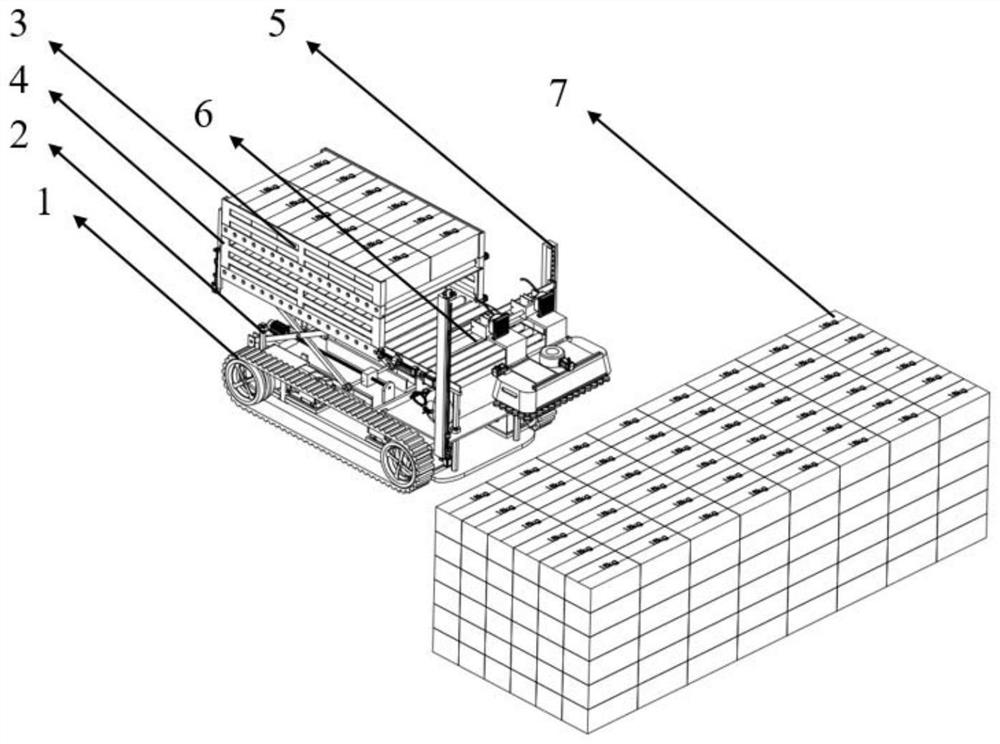

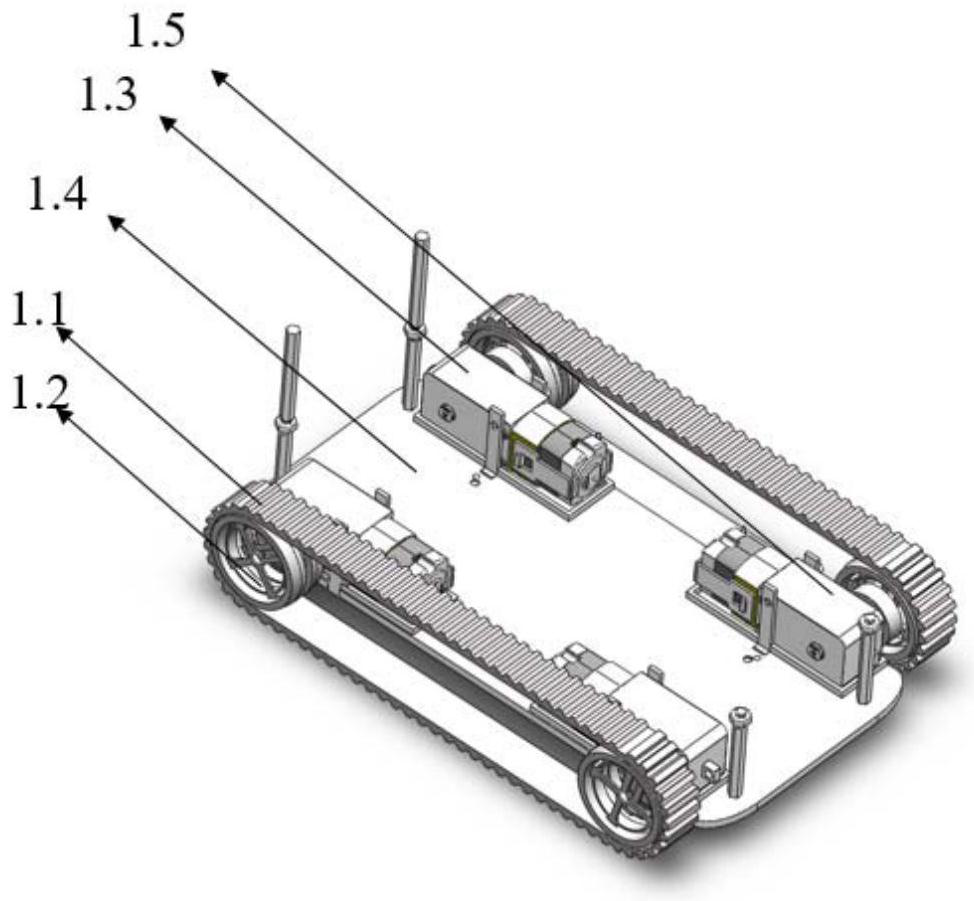

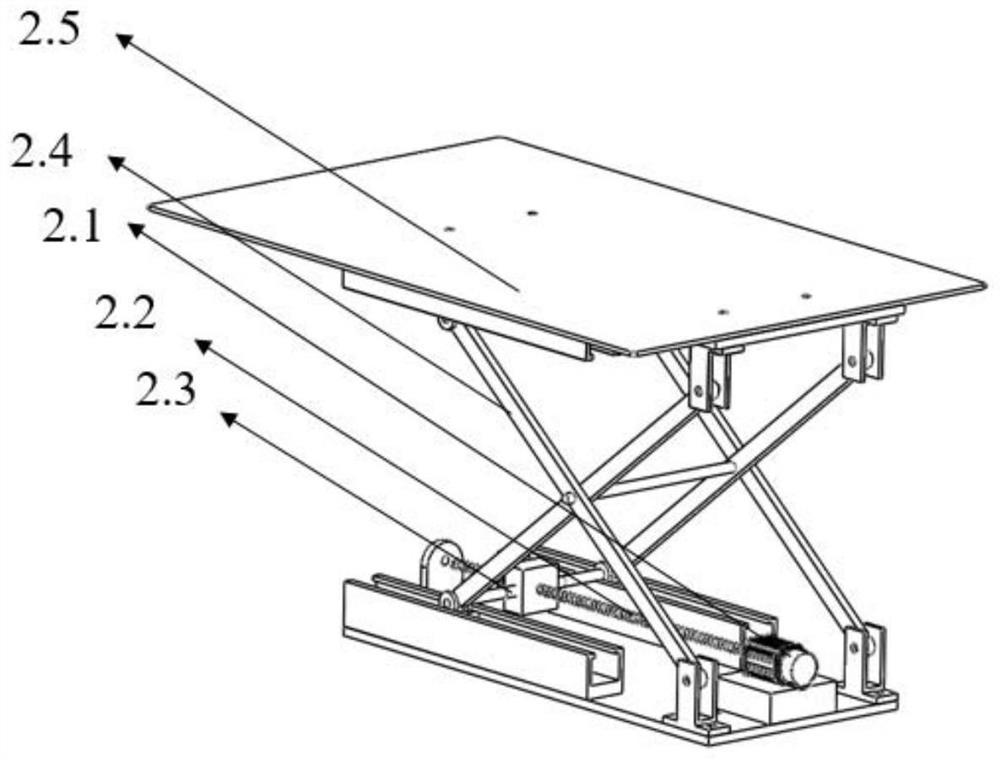

[0026] Such as figure 1 Shown is a new type of pneumatic suction cup crawler robot used in the transfer of cargo in the cabin, including a crawler chassis 1, a cargo lift platform 2, a double-layer cargo compartment 3, a liftable tailgate for the cargo compartment 4, a cargo suction and lifting device 5, and a cargo transfer The device 6 and the cargo 7 and the crawler chassis 1 are used to provide power for the pneumatic suction cup crawler robot, so that the robot is close to the cargo 7 . The cargo hold lifting platform 2 is installed above the crawler chassis 1, and is used for lifting the double-deck cargo compartment 3. The double-layer cargo receiving cabin 3 is connected to the carg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com