Storage box and transfer vehicle

A storage box and storage layer technology, applied in the direction of covering/external paint, internal accessories, etc., can solve the problems of limited types, inability to store, and low versatility of storage boxes, and achieve high versatility and increase the storage quantity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

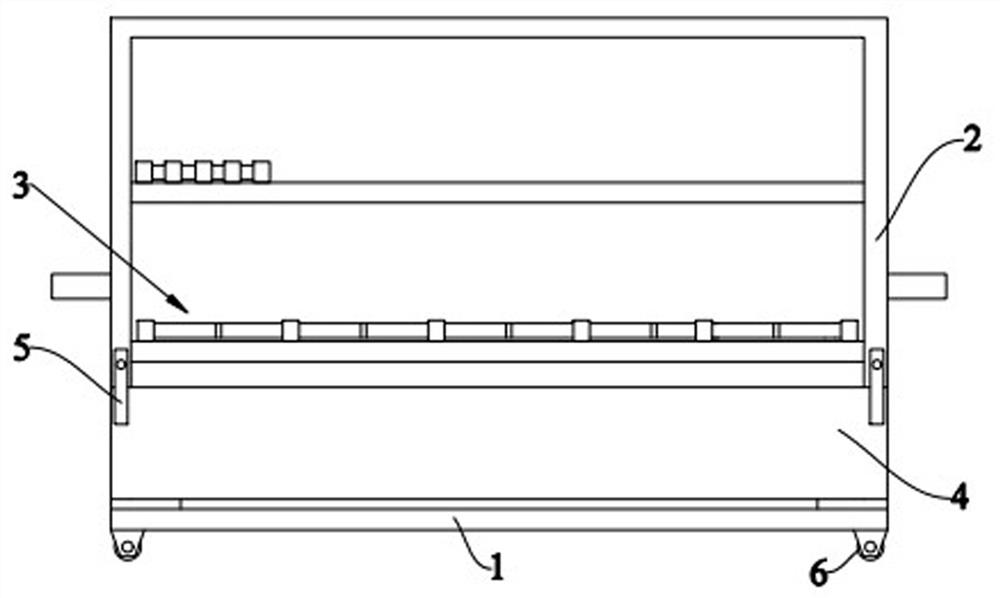

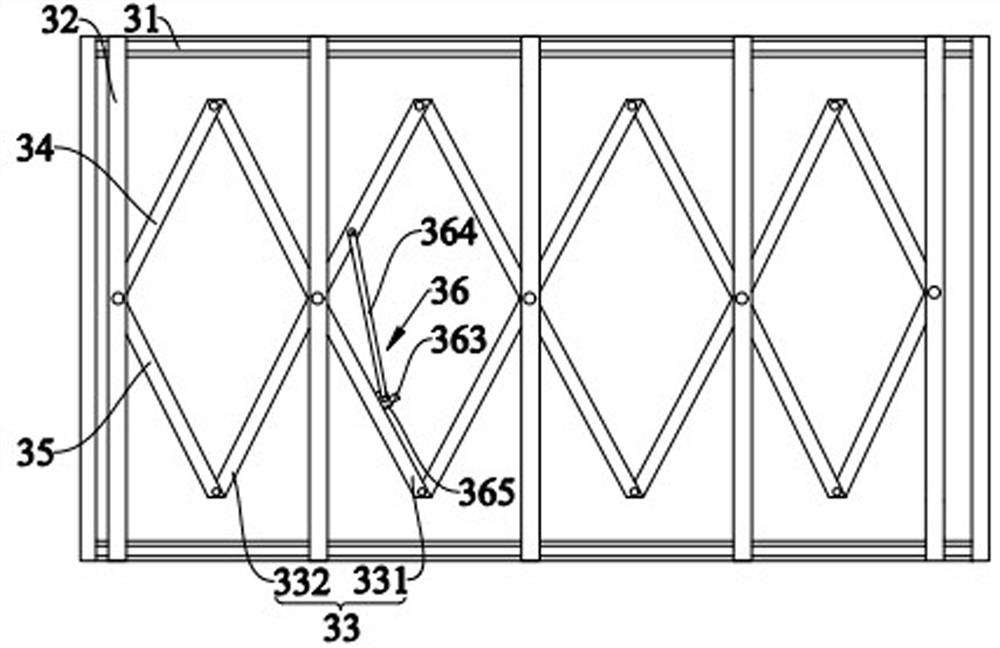

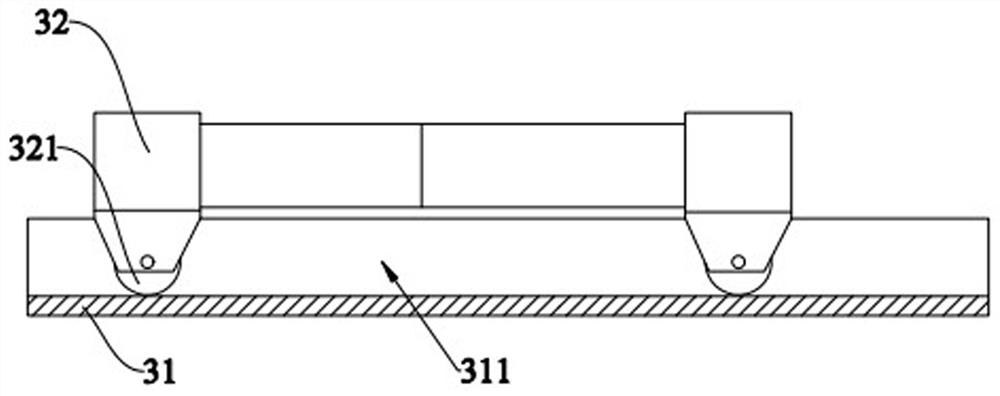

[0048] This embodiment provides a storage box, please refer to figure 1 and figure 2, the storage box includes a bottom plate 1 and a frame body 2 fixedly connected to the bottom plate 1, the bottom plate 1 can carry materials, the storage box also includes at least one storage layer 3, and each storage layer 3 includes two support rods 31, a plurality of support rods 32. Telescopic frame 33, two third connecting rods 34, two fourth connecting rods 35 and locking structure 36, two supporting rods 31 are arranged in parallel along the width direction of the bottom plate 1, and the two supporting rods 31 are fixedly connected to the frame body 2, a plurality of struts 32 are arranged in parallel along the length direction of the struts 31, the struts 32 on both sides of the head and tail are selectively fixedly connected to the ends of the struts 31, and the rest of the struts 32 are slidably connected to the struts 31, except The struts 32 outside the head and tail both sides...

Embodiment 2

[0062] Compared with Embodiment 1, the difference of this embodiment is that the locking structure 36 also includes a second connecting rod (not shown in the figure), and one end of the second connecting rod is rotatably connected to the second connecting rod 332 and the first connecting rod 332 . One of the first rack 361 is not provided in the rod 331, the driver 363 is connected to the other end of the second connecting rod, the second rack 362 is fixedly connected to the movable end of the driving member 363, the second connecting rod can make the second The rack 362 is facing the first rack 361 . Wherein, when the four poles 32 except the first or the last pole 32 move in the horizontal direction, the positions of the first rack 361 and the second rack 362 change, and the second connecting rod can drive the second The rack 362 rotates together, so that the second rack 362 and the first rack 361 face each other, and the driving member 363 drives the second rack 362 to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com