Recycling device for 3D printing supplies

A recycling device, 3D printing technology, applied in mechanical material recycling, processing recycling, plastic recycling, etc., can solve problems such as incomplete crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in combination with specific embodiments.

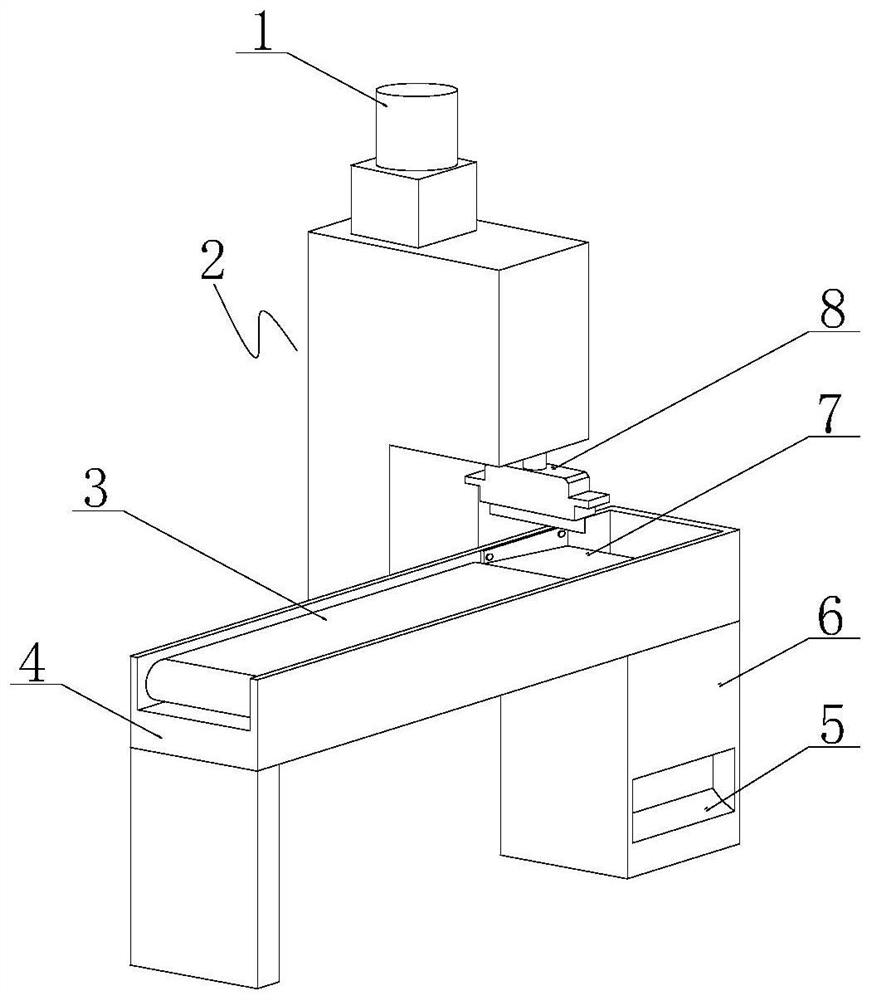

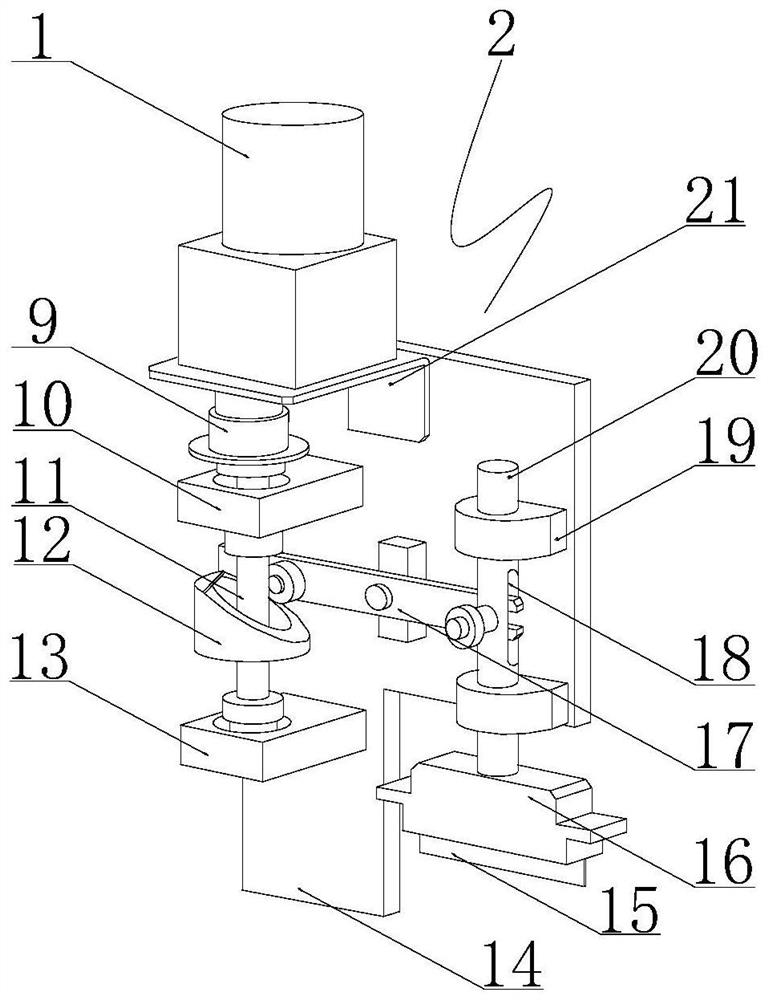

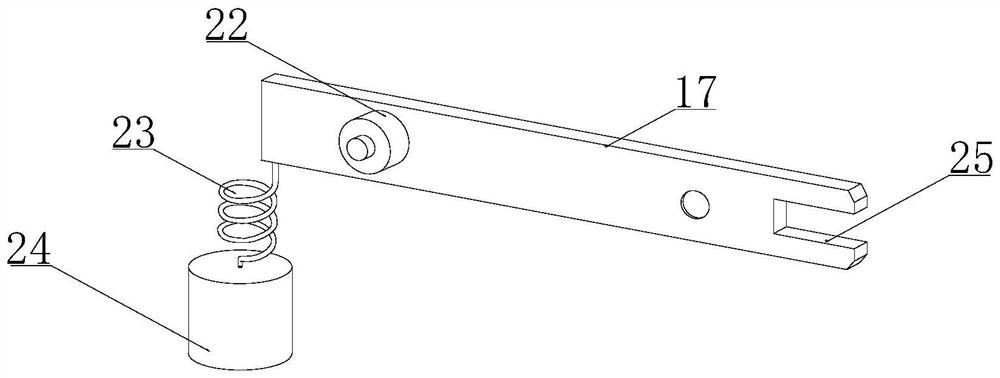

[0028] exist figure 1 , 2 A recycling device for 3D printing consumables provided in and 3 includes a bracket 4 and a cutting mechanism 2 fixedly installed on one side of the bracket 4. The cutting mechanism 2 is mainly used for shredding 3D printing consumables and initially processing waste materials. The volume of the waste is reduced, which is beneficial to the later crushing, and prevents the clogging of the later processing due to the excessive volume of the waste. The bracket 4 is used to support the cutting mechanism 2. At the same time, in order to facilitate the transportation of waste, a track is provided on the bracket 4. 3. The waste material can be conveyed by the crawler belt 3, so that the waste material can be transported to the lower part of the cutting mechanism 2 for easy cutting. The cutting mechanism 2 includes a cutting box 14 fixed on the side of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com