Tool for welding steel junction box and welding method

A junction box and tooling technology, which is applied in the direction of manufacturing tools, welding equipment, welding equipment, etc., can solve the problem of inability to realize batch welding operations of junction box and grounding jumper wiring, delay in the processing and production period of junction box, and inaccurate positioning of junction box and other problems, to achieve the effect of good promotion and use value, simple structure and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

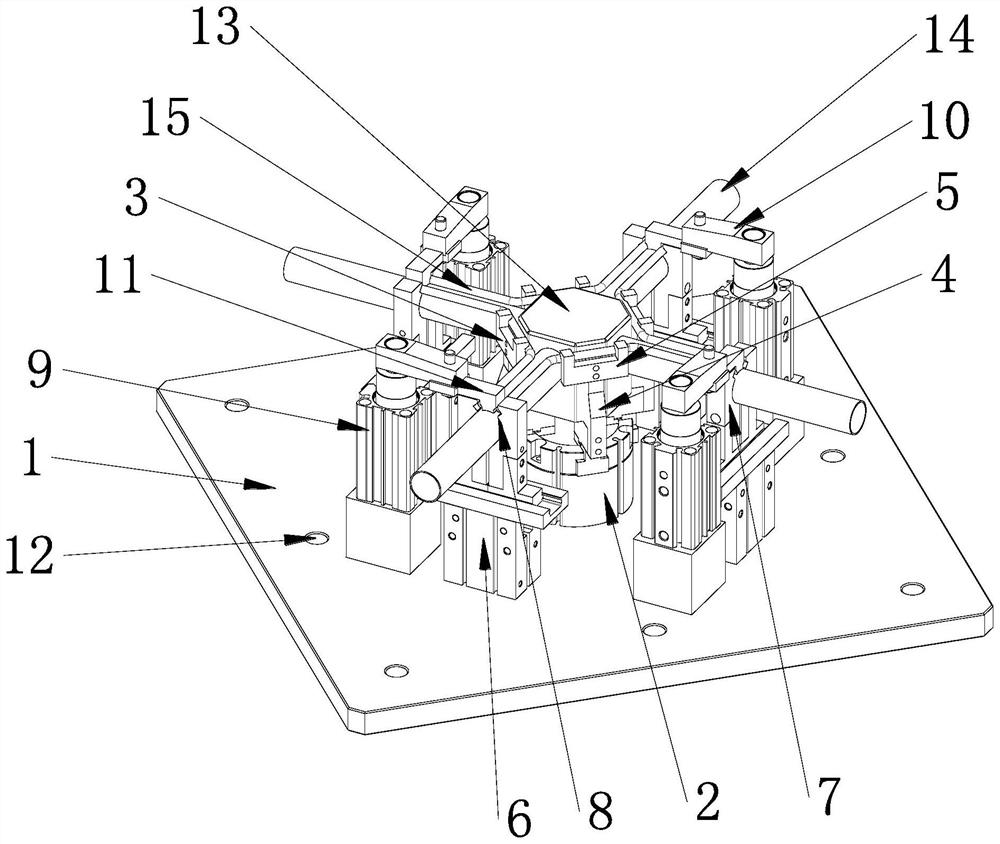

[0033] as attached figure 1 As shown, the steel junction box welding tooling of the present invention has a structure including a reference plate 1, which is square, and a number of evenly distributed installation holes 12 are opened on the outer edge of the square reference plate 1. The central position of the reference plate 1 is equipped with a clamping mechanism for the middle part of the grounding jumper wire, and four junction box wire tube clamping mechanisms are installed outside the middle part of the ground jumper wire clamping mechanism, and the four junction box wire tube clamping mechanisms are square and uniform Distributed on the reference plate 1, a grounding jumper end clamping mechanism is installed between two adjacent junction box wire tube clamping mechanisms, and the grounding jumper end clamping mechanism is spaced from the junction box wire tube clamping mechanism and grounded The clamping mechanism at the end of the jumper wire is located at the corner...

Embodiment 2

[0038] Steel junction box welding method of the present invention, this method is specifically as follows:

[0039] S1, open the jaw one 3 of the air claw cylinder one 2, open the jaw two 7 of the air claw cylinder two 6, and open the clamping cylinder 9 to the highest point;

[0040] S2. Put the junction box 13 above the jaw one 3;

[0041] S3, put the grounding jumper wire 15 on the wire tube 14 of the junction box;

[0042] S4, start the air claw cylinder one 2, and clamp the middle part of the junction box 13 and the ground jumper 15 through the clamp claw one 3;

[0043] S5, start the air claw cylinder 2 6, clamp the end of the junction box line pipe 14 by the jaw 2 7, and simultaneously position the grounding jumper wire 15;

[0044] S6, start the clamping cylinder 9, and clamp the end of the ground jumper 15 through the pressing plate 11;

[0045] S7, welding junction box 13 and ground jumper wire 15;

[0046] S8. After the welding operation is completed, open the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com