Multiple anti-blocking type raw material crushing device for ointment production

A raw material crushing and multiplexing technology, applied in grain processing and other directions, can solve problems such as easy hole blocking and affecting processing efficiency, and achieve the effect of ensuring vibration effect, avoiding hole blocking phenomenon, and improving practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

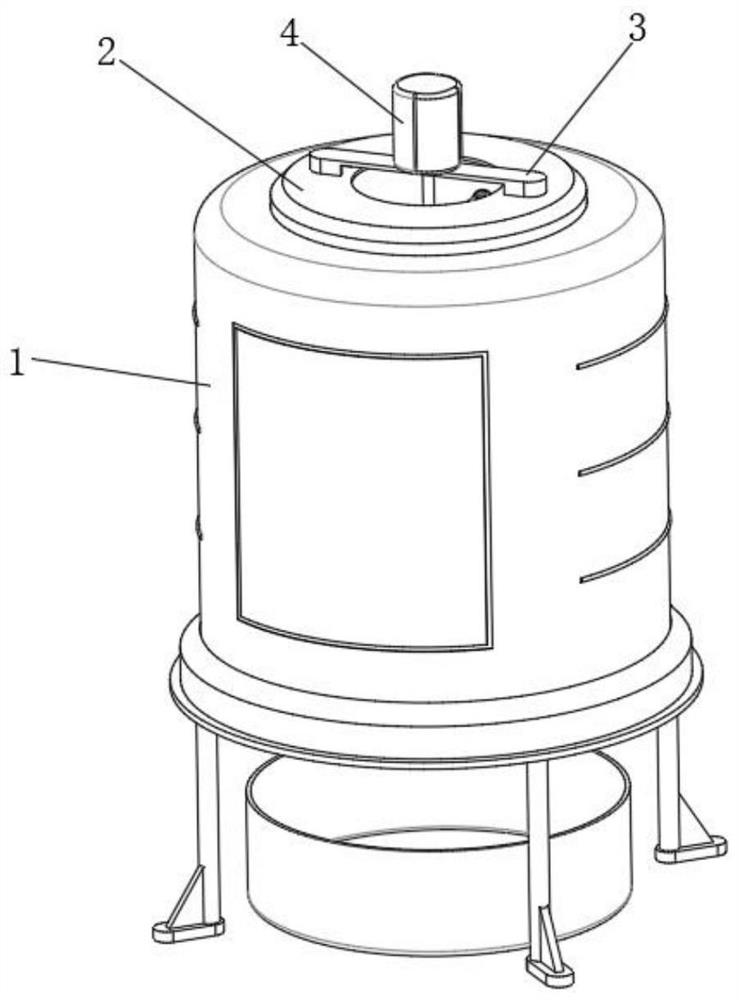

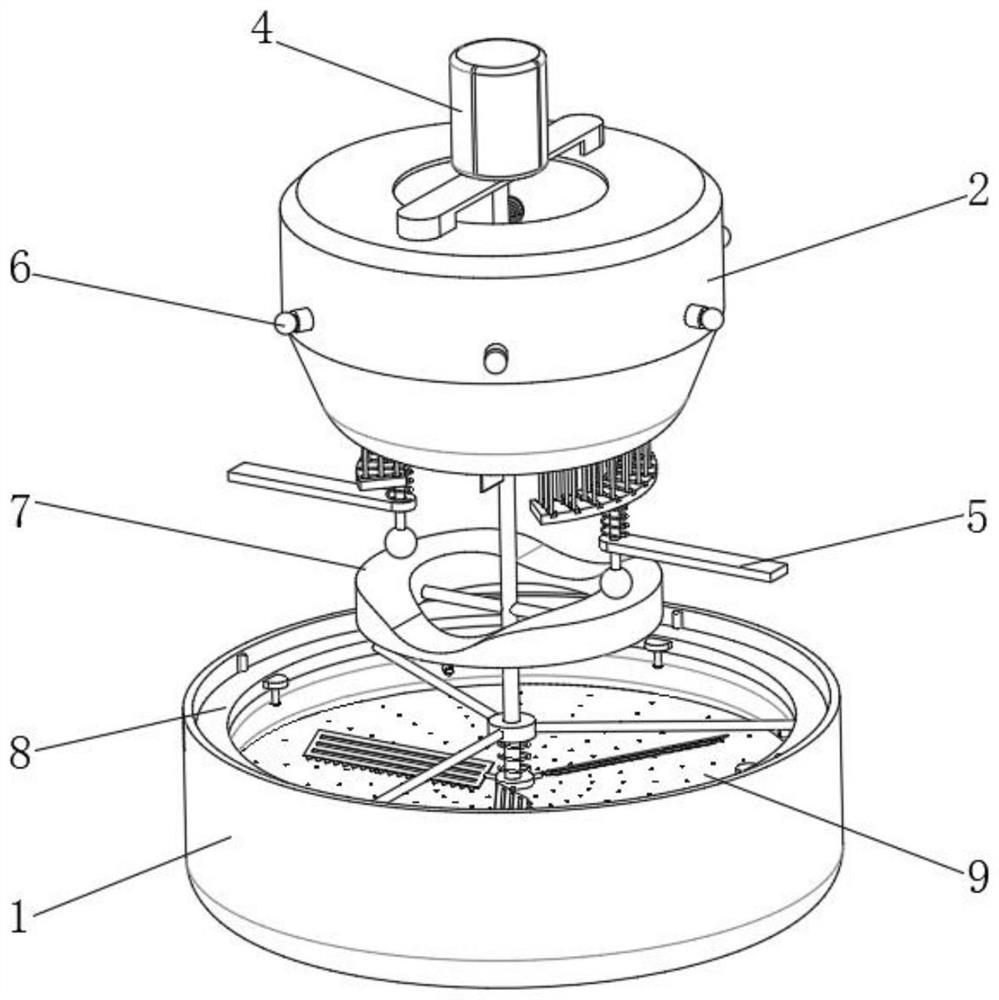

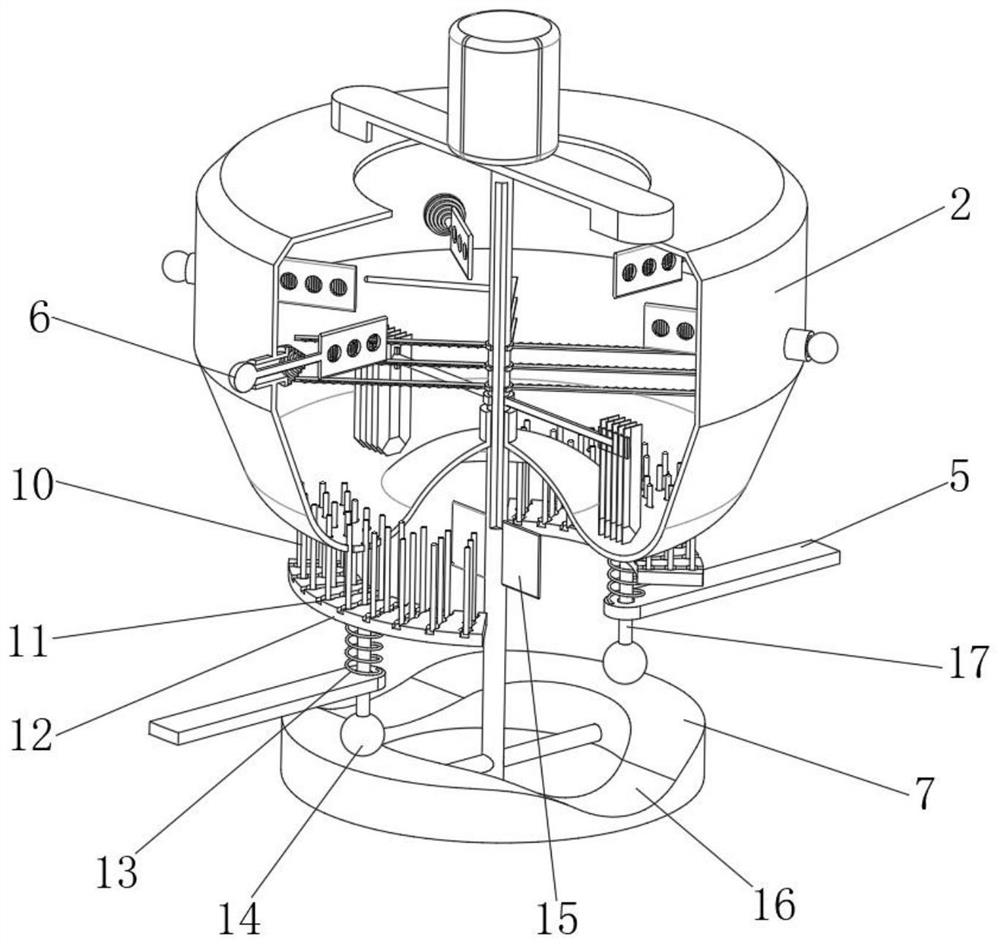

[0041] A multiple anti-blocking type raw material crushing device for ointment production, such as Figure 1-8 As shown, the crushing tank 1 is included, the crushing tank 1 is provided with a primary crushing chamber 2, the crushing tank 1 is provided with a primary crushing mechanism, and the primary crushing mechanism includes a second crushing knife 22 and a first crushing knife 21, The top of the primary pulverizing chamber 2 is equipped with a motor 4 through a fixed frame 3, and the output end of the motor 4 is connected to a rotating main shaft 27, and the second pulverizing knife 22 and the first pulverizing knife 21 are fixed on the circumference of the rotating main shaft 27. On the outer wall, the bottom of the primary crushing chamber 2 is integrally provided with an annular recess 20, and the bottom of the annular recess 20 is provided with a first sieve hole 19, and the movement track of the first crushing knife 21 is adapted to the shape of the annular recess 20...

Embodiment 2

[0051] A multiple anti-blocking type raw material crushing device for ointment production, such as Figure 1-8 As shown, in order to facilitate secondary crushing; this embodiment makes the following improvements on the basis of Embodiment 1: the secondary crushing mechanism includes a third crushing knife 28 and a sieve plate 9, and the sieve plate 9 is fixed to the crushing plate 9 by screws. The circumferential inner wall of the tank 1 and the top of the sieve plate 9 are provided with evenly distributed second sieve holes 34, and the third pulverizing knife 28 is installed on the outer wall of the bottom of the rotating main shaft 27; multiple pulverization is realized by setting the third pulverizing knife 28 and other structures function to improve the crushing effect.

[0052] In order to prevent the second sieve hole 34 from blocking; as Figure 6-8 As shown, an annular elastic bag 32 is fixed on the outer side of the top of the sieve plate 9, and the side of the annu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com