Method for improving storage stability of konjaku flour

A technology of storage stability and konjac flour, applied in the field of konjac processing, can solve the problems of limited effect and the like, and achieve the effects of being beneficial to processing or storage, improving state stability, and reducing storage conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

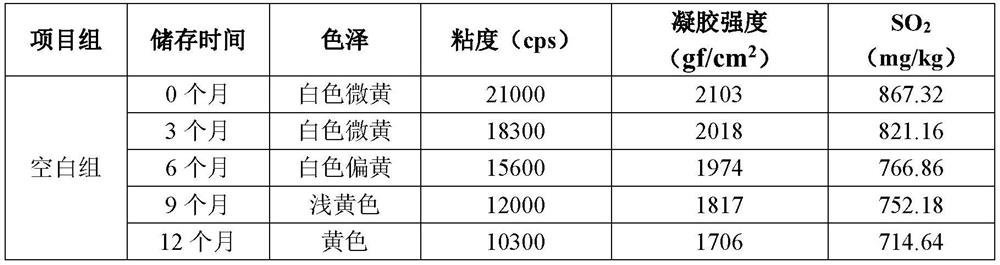

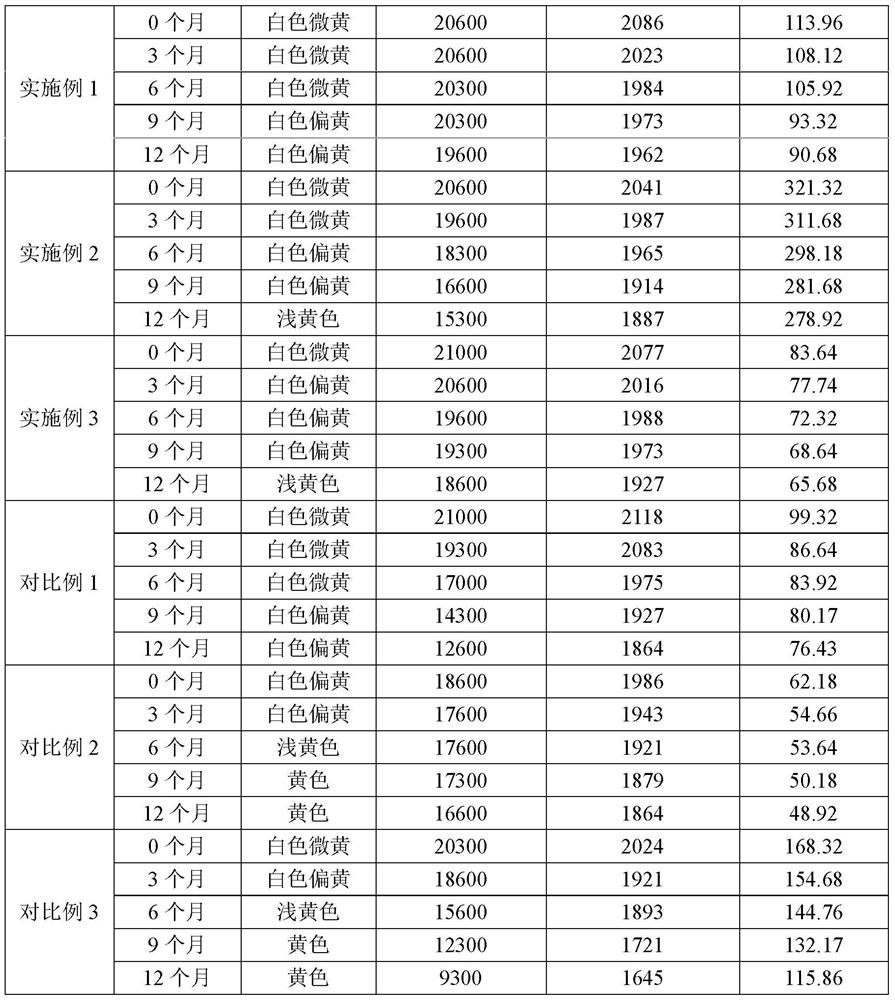

Examples

Embodiment 1

[0028] 1. Add 25% of its own mass of sodium sulfite aqueous solution to ordinary konjac powder, and mix quickly; wherein the mass concentration of sodium sulfite aqueous solution is 0.4%;

[0029] 2. Mix the materials prepared in step 1 at 8°C for 20 minutes;

[0030] 3. Add its quality as 25% citric acid aqueous solution to the material treated in step 2, mix quickly and uniformly, and the concentration of citric acid aqueous solution is 0.1%;

[0031] 4. The konjac flour watered material prepared in step 3 was heat-treated at 100° C. (steam heating) at normal pressure for 8 minutes;

[0032] 5. Freeze-dry the konjac flour in step 4 until the water content is less than 10%;

[0033] 6. Add citric acid-phosphate buffer solution to the dried konjac powder again, and the addition is 35% of the dry state konjac powder quality, and it is placed at room temperature for 3.5 hours; sampling and adding water to make konjac powder content is a mixed solution of 1% (with dry base), it...

Embodiment 2

[0036] 1. Add 20% of its own mass of sodium sulfite aqueous solution to ordinary konjac powder, mix quickly and uniformly, and the mass concentration of sodium sulfite aqueous solution is 0.1%;

[0037] 2. Mix the materials prepared in step 1 at 5°C for 30 minutes;

[0038] 3. Add 20% citric acid aqueous solution to the material treated in step 2, mix quickly and uniformly, and the concentration of citric acid aqueous solution is 0.05%;

[0039] 4. The konjac flour watered material prepared in step 3 was heat-treated at 102° C. for 5 minutes under normal pressure;

[0040] 5. Freeze-dry the konjac flour in step 4 until the water content is less than 10%;

[0041] 6. Add citric acid-sodium citrate buffer solution to the konjac flour after drying, the addition is 25% of the dry state konjac flour quality, and place it at room temperature for 2 hours; sampling and adding water to make a mixed solution of 1% konjac flour content, Measure its pH value to be 4.2;

[0042] 7. Free...

Embodiment 3

[0044] 1. Add 30% of its own mass of sodium pyrosulfite aqueous solution to ordinary konjac powder, and mix quickly; the mass concentration of sodium pyrosulfite aqueous solution is 1%;

[0045] 2. Mix the materials prepared in step 1 at 10°C for 10 minutes;

[0046] 3. Add its quality as 30% citric acid aqueous solution to the processed material in step 2, mix quickly and uniformly, and the concentration of citric acid aqueous solution is 0.18%;

[0047] 4. The konjac flour watered material prepared in step 3 was heat-treated at a saturated 105°C and normal pressure for 8 minutes;

[0048] 5. Freeze-dry the konjac flour in step 4 until the water content is less than 10%;

[0049] 6. Add phosphoric acid-potassium dihydrogen phosphate buffer solution to the konjac flour after drying, the addition is 45% of the dry state konjac flour quality, and place it at room temperature for 4.5 hours; adding water to make a mixed solution of 1% konjac flour content, Measure its pH value t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com