UHT milk and preparation method thereof

A technology of algae oil and microbial oil, which is applied in the direction of milk preparations, dairy products, milk preservation, etc., can solve the problems of difficult control of liquid milk addition process, easy oxidation of unsaturated fatty acid oil, complex composition of DHA powder, etc. Achieve important application value, reduce fishy smell, and excellent oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

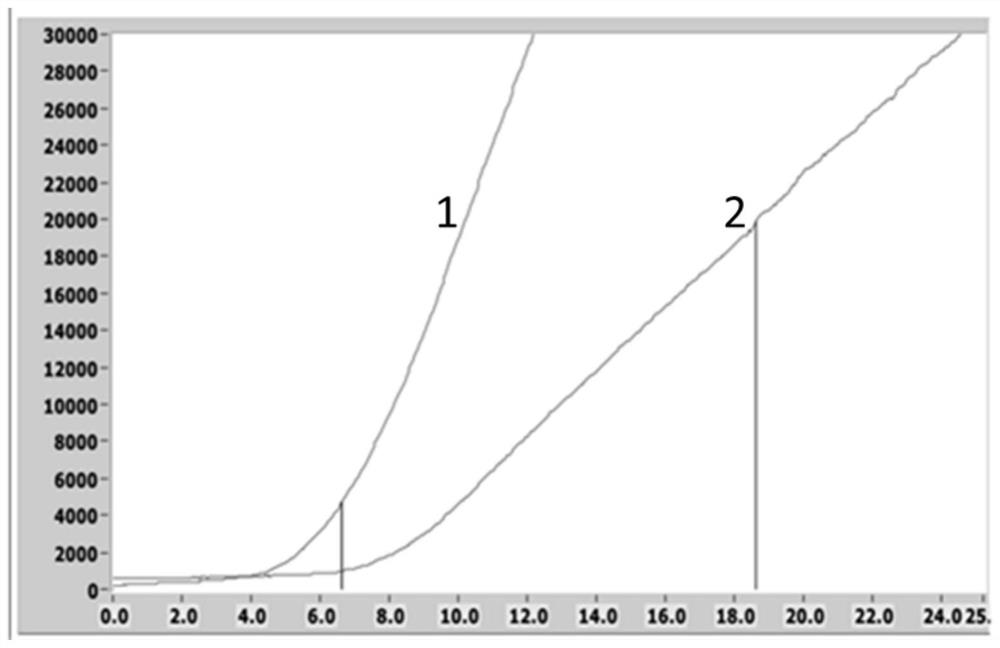

Image

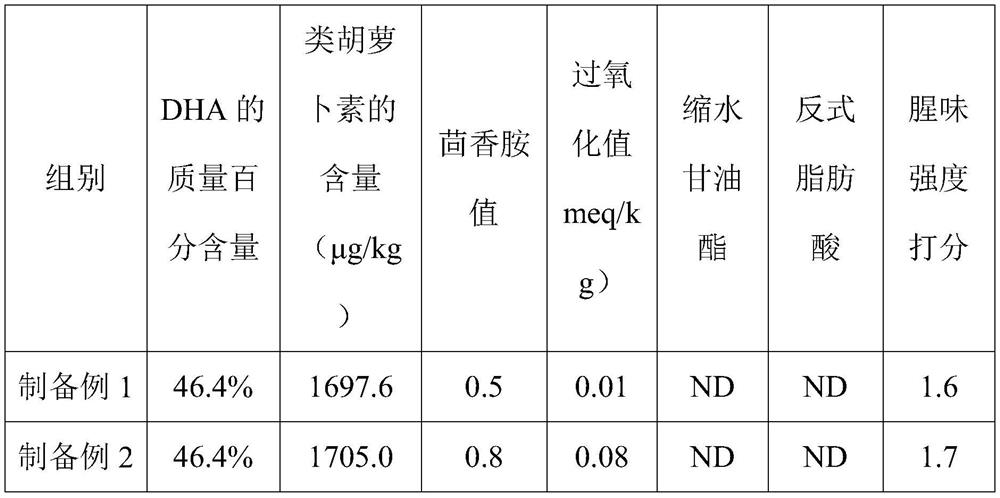

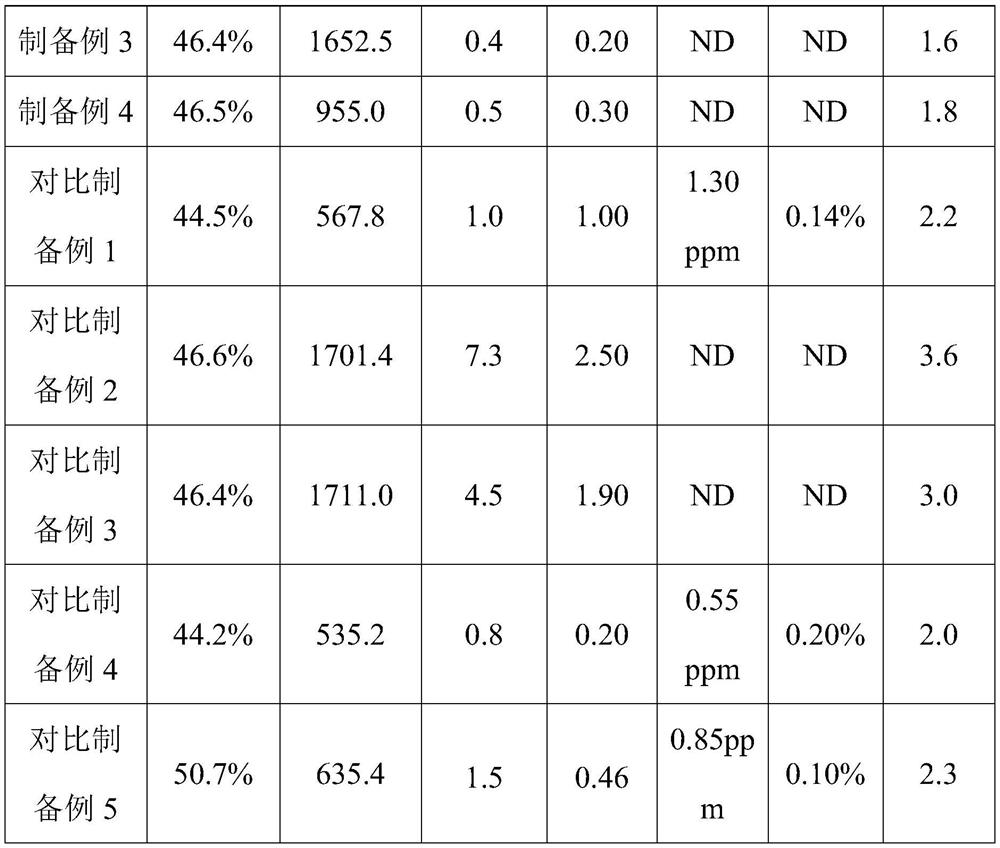

Examples

preparation example 1

[0064] This preparation example provides a kind of DHA algae oil, and its preparation method is as follows:

[0065] (1) Get microbial oil 2000kg, add citric acid solution (concentration is 50wt%) wherein, the amount of acid that adds is 4wt% of microbial oil amount, 80 ℃ of reaction 60min, grease sedimentation 4h, after separating precipitation, continue to grease Add citric acid solution (concentration is 50wt%), the amount of acid added is 2wt% of the amount of microbial oil, react at 80 ° C for 60min, the grease settles for 3h, separate the grease, add 30wt% sodium hydroxide solution, the amount of alkali added is microbial 3 wt% of the oil content, react at 80°C for 60 minutes, settle the oil for 4 hours, filter and separate the oil, and obtain the microbial oil after alkali refining.

[0066] (2) Add activated clay to the microbial oil after alkali refining obtained in step (1), the addition of activated clay is 2wt% of the microbial oil amount, at 50°C and 800pa, stir f...

preparation example 2

[0069] This preparation example provides a kind of DHA algae oil, and its preparation method is as follows:

[0070] (1) Get the mixture of microbial oil and cell debris (the mass percentage of microbial oil in the mixture is 50%), keep it at 80°C for 60min, obtain 2000kg of grease after centrifugation and precipitation, mix it with 200kg of water, and settle the grease for 4h, After filtering and separating the precipitate, repeat the above degumming operation once again to obtain the degummed microbial oil.

[0071] (2) add gac to the degummed microbial oil that step (1) obtains, the add-on of gac is 3wt% of the microbial oil amount, at 50 ℃, 800pa, stir 30min, filter after stirring, remove adsorbent, Obtain the decolorized microbial oil.

[0072] (3) Put the decolorized microbial oil obtained in step (2) into a deodorizing tower with a vacuum degree of 800 pa, feed in steam at 90° C., keep at 150° C. for 120 minutes and then drop to normal temperature to obtain the DHA alg...

preparation example 3

[0074] This preparation example provides a kind of DHA algae oil, and its preparation method is as follows:

[0075] (1) Get microbial oil 2000kg, add citric acid solution (concentration is 50wt%) wherein, the amount of acid that adds is 4wt% of microbial oil amount, 80 ℃ of reaction 60min, grease sedimentation 4h, after separating precipitation, continue to add grease again Add citric acid solution (concentration is 50wt%), the amount of acid added is 2wt% of microbial oil amount, 70 ℃ of reaction 80min, grease sedimentation 3h, separate grease, add 30wt% sodium hydroxide solution again, the amount of alkali that adds is 3wt% of the amount of microbial oil, after reacting at 80°C for 60 minutes, the grease settled for more than 4 hours, and the grease was separated by filtration to obtain the microbial oil after alkali refining.

[0076] (2) Add clay to the microbial oil after alkali refining obtained in step (1), the addition of clay is 2.0wt% of the microbial oil, at 50°C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com