Plastic formula and draw-bar box shell mold

A trolley box and box shell technology, applied in the direction of coating, etc., can solve the problems of low impact resistance, high heat loss, uneven heating of plastic raw materials, etc., achieve good toughness and use strength, reduce heat loss, and good impact resistance characteristic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

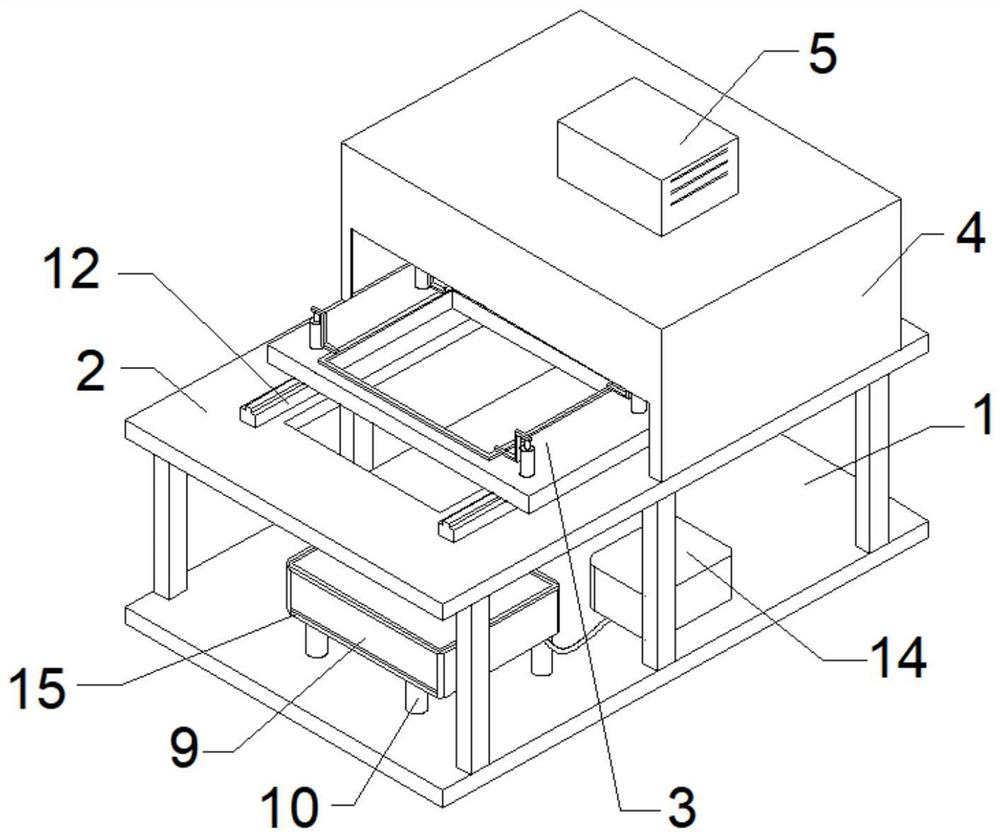

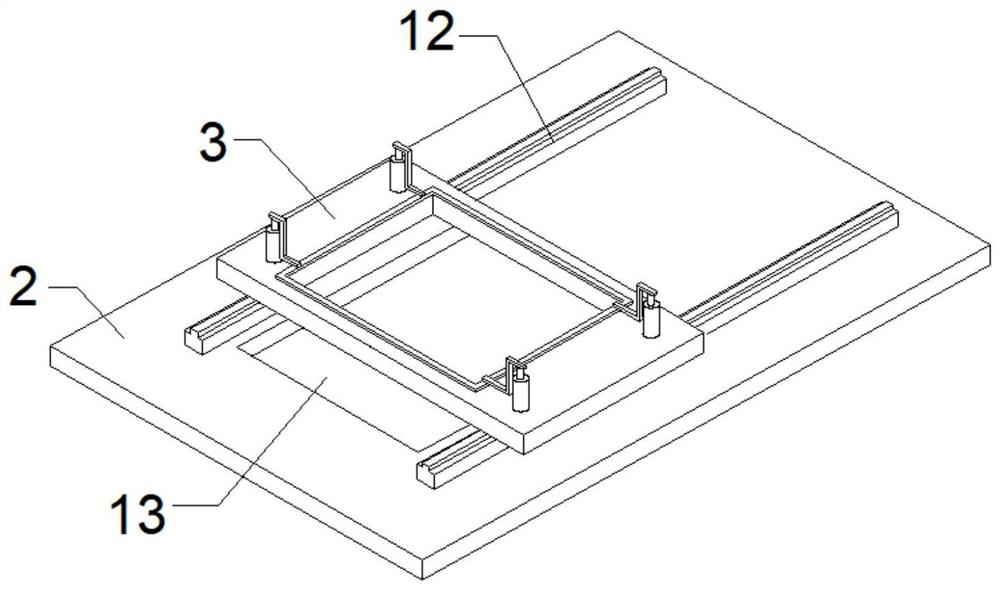

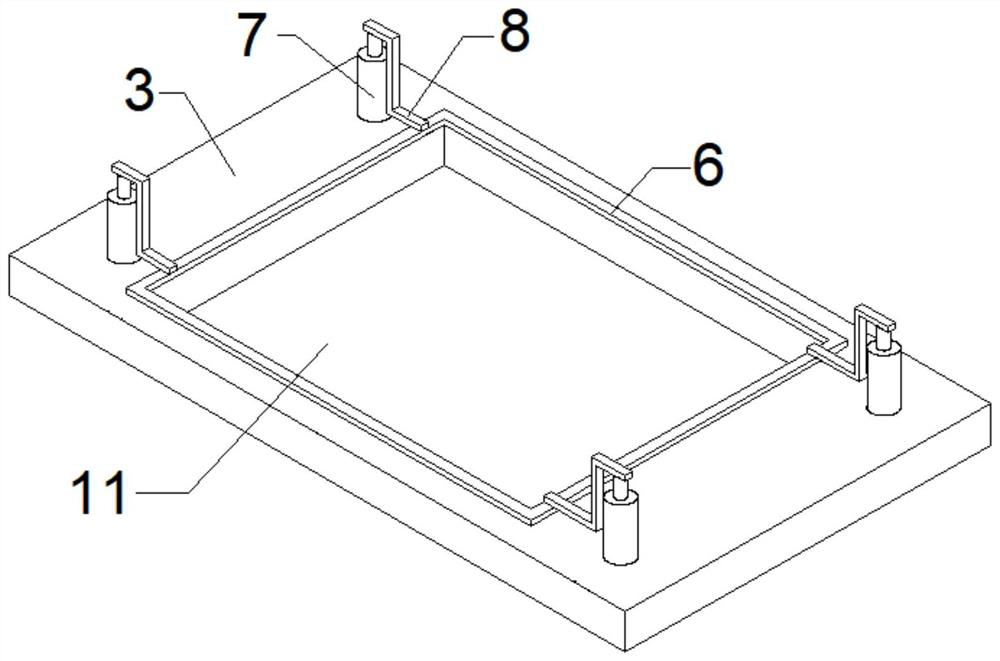

[0027] Such as Figure 1-3 As shown, a trolley box shell mold includes a base 1, a support platform 2 and a material platform 3, and also includes a pressure frame 6, a protective cover 4 and a hot air blower 5, and the top of the base 1 is equipped with a support platform 2 through bolts. One end of the top of the support platform 2 is equipped with a protective cover 4 by bolts, one end of the top of the base 1 is provided with a module 9, and the other end of the top of the support platform 2 is provided with a push-up groove 13 corresponding to the module 9, and the support platform 2 On the top and on both sides of the push-up groove 13, electric slide rails 12 are respectively installed through bolts. The top of the sliding block of the electric slide rail 12 is equipped with a material platform 3 through bolts, and a material push groove 11 is provided on the material platform 3. A pressing frame 6 corresponding to the pushing groove 11 is opened on the material table 3...

Embodiment 2

[0040] Such as Figure 1-3 As shown, a trolley box shell mold includes a base 1, a support platform 2 and a material platform 3, and also includes a pressure frame 6, a protective cover 4 and a hot air blower 5, and the top of the base 1 is equipped with a support platform 2 through bolts. One end of the top of the support platform 2 is equipped with a protective cover 4 by bolts, one end of the top of the base 1 is provided with a module 9, and the other end of the top of the support platform 2 is provided with a push-up groove 13 corresponding to the module 9, and the support platform 2 On the top and on both sides of the push-up groove 13, electric slide rails 12 are respectively installed through bolts. The top of the sliding block of the electric slide rail 12 is equipped with a material platform 3 through bolts, and a material push groove 11 is provided on the material platform 3. A pressing frame 6 corresponding to the pushing groove 11 is opened on the material table 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com