Control system and control method of reluctance motor for rapier loom spindle

A technology of rapier loom and control system, applied in the direction of control system, AC motor control, loom, etc., can solve the problems of short development cycle, low work efficiency, low integration, etc., to reduce control cost and high work efficiency , the effect of improving the integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

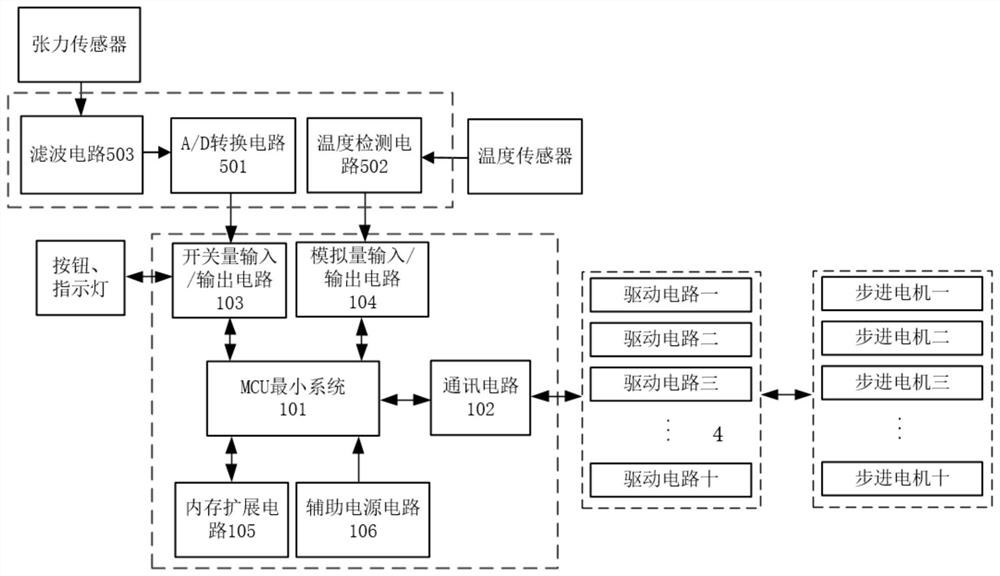

[0047] The present invention provides a control system of a reluctance motor for the main shaft of a rapier loom (abbreviated as a control system), which is characterized in that the control system includes a main control module 1, an electric power transmission volume control module 2, a main shaft driving module 3, Weft selection and stranding control module 4 and tension / temperature detection module 5;

[0048] The main control module 1 includes an MCU minimum system 101, a communication circuit 102, a digital input / output circuit 103 and an analog input / output circuit 104;

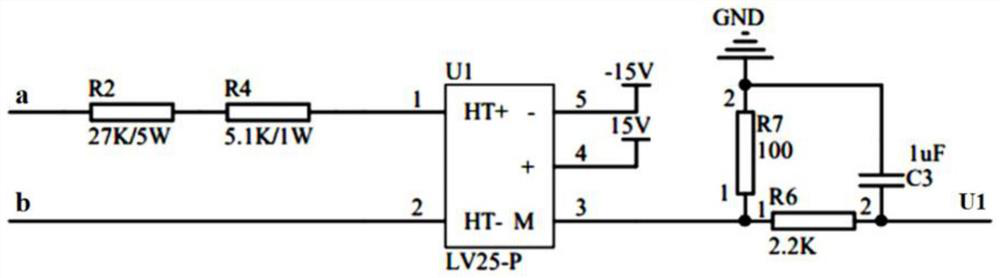

[0049] The power transmission volume control module 2 is used to regulate the warp tension, and then provide a suitable tension environment for the operation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com