Light path debugging method and system for motor vehicle pollution detection equipment

A pollution detection and debugging method technology, applied in optics, measuring devices, optical components, etc., can solve problems such as danger, difficulty in dimming, and long time consumption, and achieve the effect of saving labor costs and time costs, and solving difficulties in optical path calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

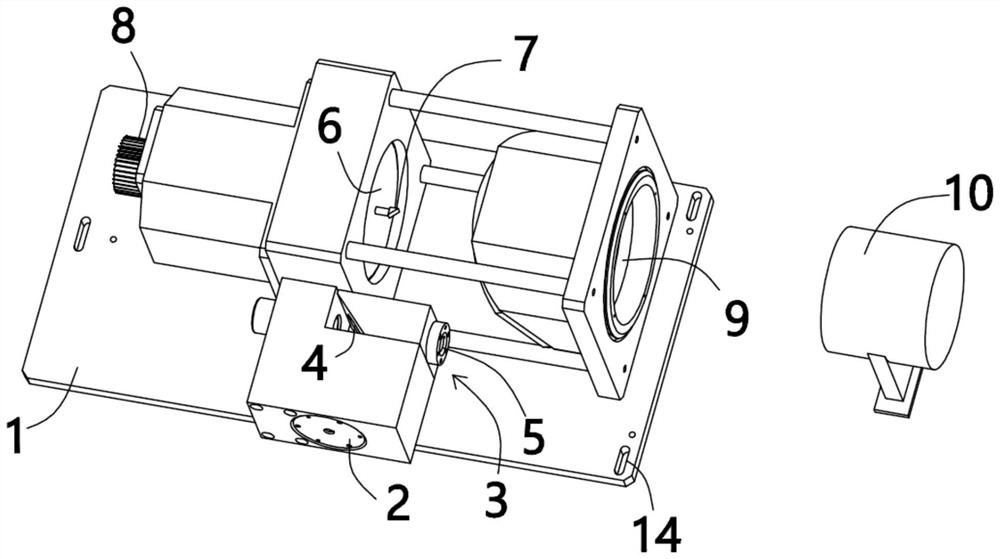

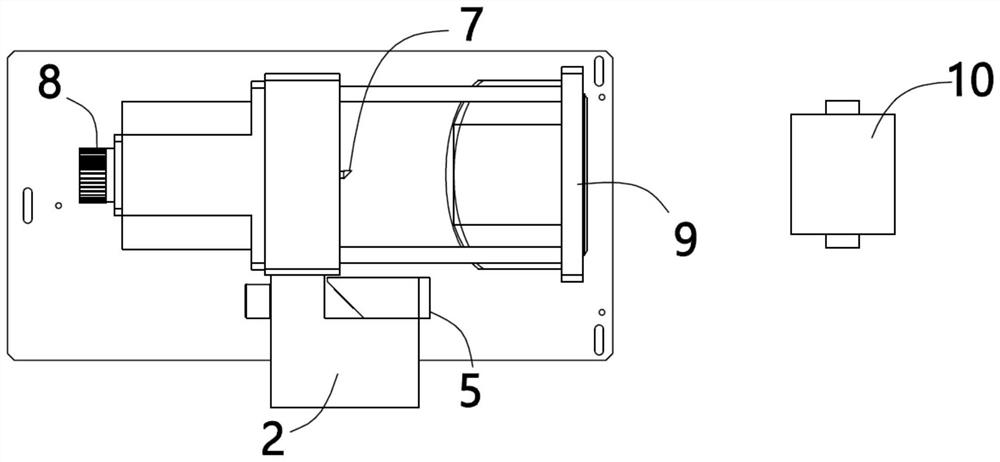

[0042] see Figure 1 to Figure 3 , the present invention provides a technical solution:

[0043] A method for debugging an optical path of a vehicle pollution detection device, comprising:

[0044] A beam of infrared laser is emitted from one side to the other side after being reflected, forming the first optical path;

[0045] emitting a beam of visible light into the first light path;

[0046] Adjust the incident angle of visible light so that the visible light remains coaxial with the first optical path, and then reflect the spectrum of the infrared laser back to the original path;

[0047] The light signal of the reflected infrared laser is converted into an electrical signal, and after processing, the concentration of pollutants is calculated.

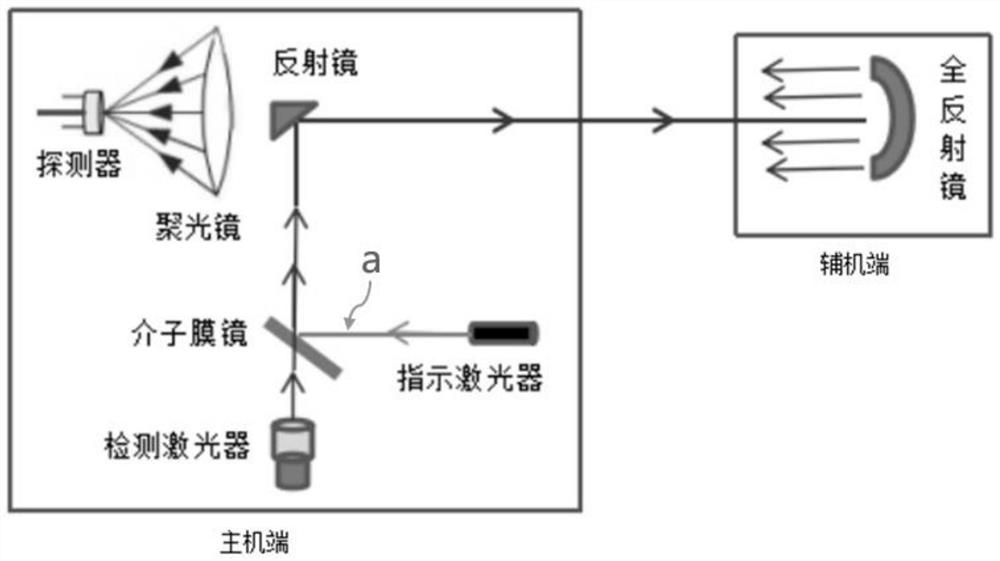

[0048] The system of this embodiment includes two major parts, the main machine end and the auxiliary machine end, which are respectively located on both sides of the road; the components contained in the main machine end are i...

Embodiment 2

[0052] see figure 1 or Figure 4 , which is basically the same as Example 1, with a slight difference:

[0053] A beam of visible light is emitted into the first optical path, and the visible light is also green light, which is emitted from the auxiliary machine end, that is, the indicator laser 5 is used to emit green light, and the indicator laser 5 is located at the auxiliary machine end side, specifically at the total reflection on the axis in the mirror 10, and then only need to refer to the light emitted by the indicator laser 5 to adjust the height and direction of the bottom plate 1: make the green light reflected by the meson film mirror 4 coincide with the marking line a, which means that the indicator laser The light remains coaxial with the light of the detection laser.

Embodiment 3

[0055] see Figure 5 to Figure 7 , which is basically the same as Example 1, with a slight difference:

[0056] The deuterium lamp 11 is used for the instruction laser emitting device 3, and the spectrometer 13 is used for the detection device. After the spectrum reaches the spectrometer, the optical signal is converted into an electrical signal, and then processed by a circuit to calculate the concentration of pollutants. The light emitted by the deuterium lamp 11 is first collimated by the collimating mirror 12 located between the meson film mirror 4 and the deuterium lamp 11 and then incident on the meson film mirror 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com