Experimental equipment for measuring internal stress of solid-state battery based on neutron diffraction

A technology of solid-state batteries and experimental equipment, applied in measuring devices, material analysis using wave/particle radiation, instruments, etc., can solve problems affecting work efficiency, inconvenient practical use, inconvenience, etc., and achieve the effect of reducing rotation shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

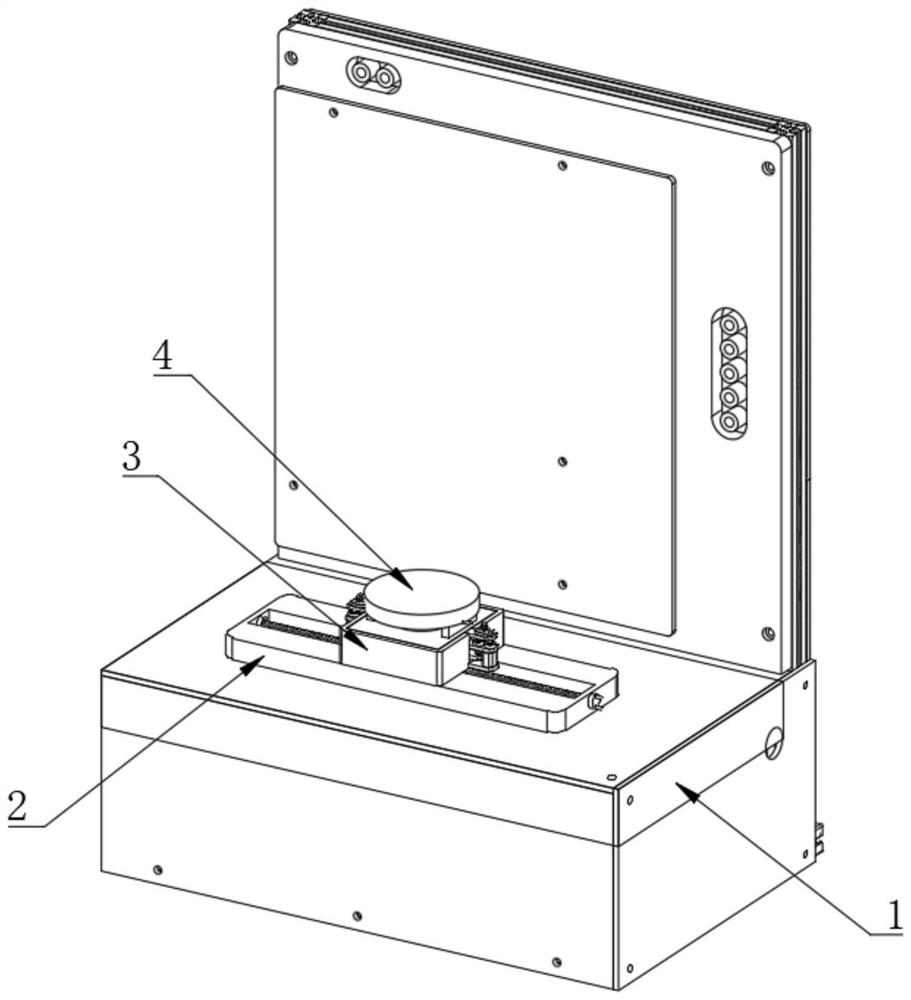

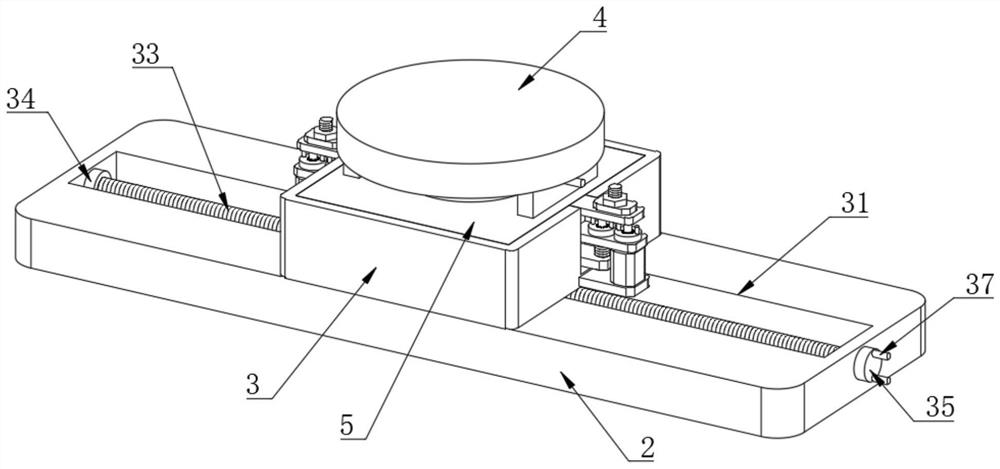

[0033] Embodiment one, by Figure 1 to Figure 8 Given, the present invention includes console body 1, the top of console body 1 is fixedly connected with fixed mounting base 2, the top of fixed mounting base 2 is provided with movable box 3, fixed mounting base 2 and movable box 3 are connected by drive assembly, The top of the movable box 3 is provided with a loading platform 4, and the movable box 3 is a cavity structure with an opening at the top. The movable box 3 is provided with a control box 5, and the control box 5 and the loading platform 4 are connected by a rotating unit. A first movable plate 6 is provided, and a second movable plate 9 is arranged below the first movable plate 6. The top of the first movable plate 6 is fixedly connected with two top plates 7, and the top inner wall of the control box 5 is provided with two through holes. 8. The first movable plate 6 and the second movable plate 9 are connected by several compression springs 10, and the second movab...

Embodiment 2

[0035] Embodiment two, on the basis of embodiment one, by Figure 7 and Figure 8 Given, the positioning assembly includes a third fixed plate 17 arranged above the first fixed plate 13, two gears 19 are arranged below the third fixed plate 17, and the top of the gear 19 is fixedly connected with a connecting column 18, and the two connecting columns 18 is connected with the third fixed plate 17 through a fixed unit, the tops of the first turntable 14 and the second turntable 15 are provided with gear grooves 20, the fixed unit includes a connecting plate 21 arranged on the top of the third fixed plate 17, and the connecting column 18 The top end runs through the third fixing plate 17, and the top of the connecting column 18 is fixedly connected with the bottom of the connecting plate 21, the top of the third fixing plate 17 is fixedly connected with the first threaded column 22, and the first threaded column 22 runs through the connecting plate 21, and The outside of the fir...

Embodiment 3

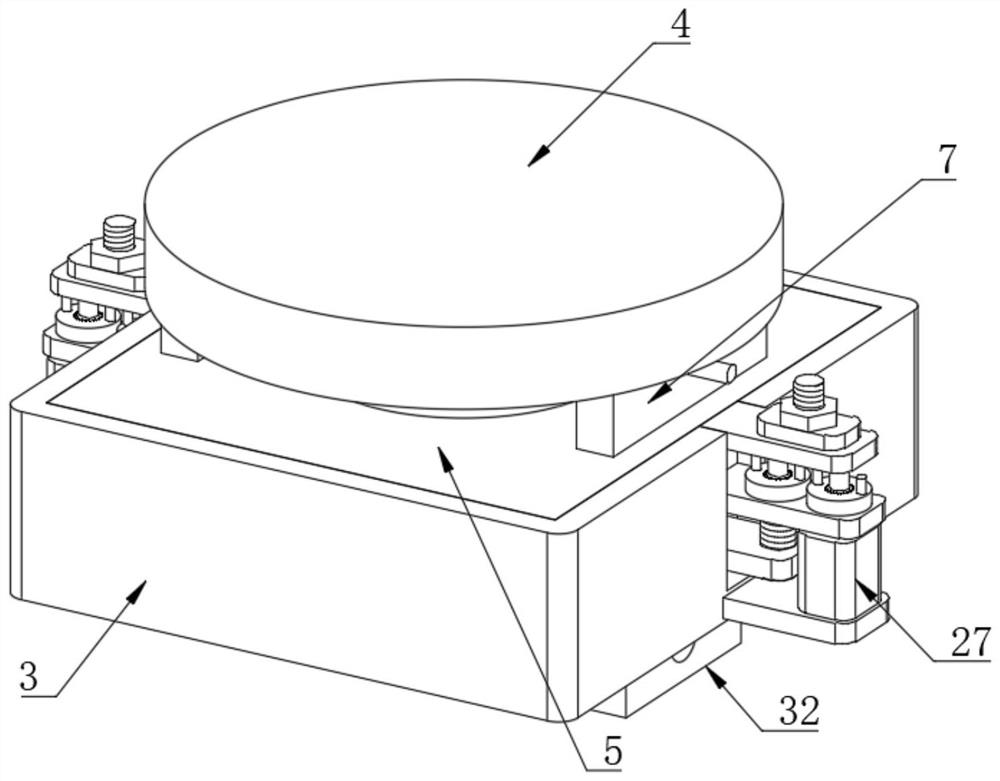

[0037] Embodiment three, on the basis of embodiment one, by Figure 4 , Figure 5 , Figure 6 and Figure 7 Given, the adjustment unit includes a second threaded post 24 arranged at the bottom of the first turntable 14, the top of the second threaded post 24 is fixedly connected with the first turntable 14, the second threaded post 24 runs through the first fixing plate 13, and the second threaded post 24 A first bearing 25 is provided at the passage between the column 24 and the first fixing plate 13, and the bottom end of the second threaded column 24 runs through the adjustment plate 12, and the connection mode between the adjustment plate 12 and the second threaded column 24 is threaded connection, and the lifting assembly Including the third threaded column 26 arranged at the bottom of the second turntable 15, the top of the third threaded column 26 is fixedly connected with the second turntable 15, the top of the second fixed plate 16 is fixedly connected with the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com