Softening and smoothing agent for acrylic yarns and preparation method of softening and smoothing agent

A technology of smoothing agent and yarn, which is applied in the field of softening and smoothing agent for acrylic yarn and its preparation, which can solve the problems that it is difficult to reach the inside of acrylic yarn, difficult to handle, and difficult to evenly absorb

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A hydrocarbon yarn with a soft slide agent, a mass of 30 parts, including 30 parts of the compound, 10 parts of the alcoholic carboxylate, 5 parts of isomeric alcohol ether, 10 parts. Part of the antine-surfactant and 50 parts of water.

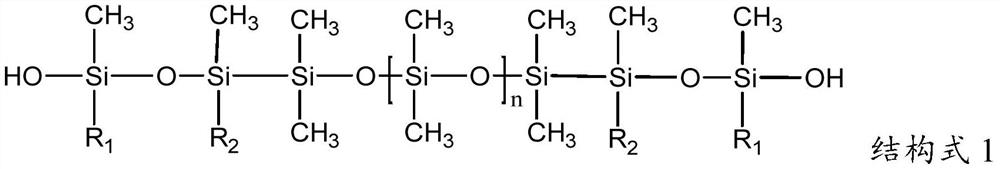

[0044] Among them, the preparation method of the compound shown in Formula 1, including steps:

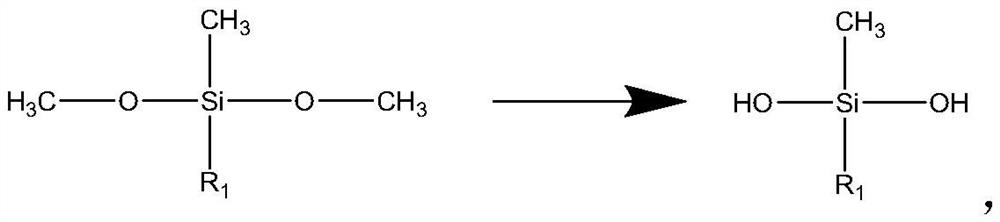

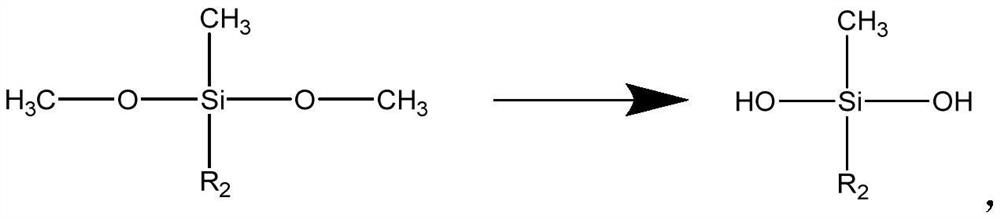

[0045] (1) N- (β-aminoethylene) -γ-aminopropanyl dimethoxysilane is hydrolyzed by hydrolyzing the first hydrolyzate, gamma-dicene troryopropyl methoxysilane The second hydrolyzate is obtained by hydrolysis.

[0046] (2) 1 mol of the first hydrolyzate and 1 mol second hydrolyzate were put into the reactor, reacted under catalyst and alkaline conditions, the temperature was 80 ° C, the time was 4 h, and the first intermediate is obtained.

[0047] (3) 1.5% of the first intermediate and linear body react under alkaline conditions, the temperature is 90 ° C, the time is 5 h, and the viscosity is 40000 cp to obtain a compound of formula 1.

[0048] ...

Embodiment 2

[0051]A hydraulic lane with a softening agent, a mass of 40 parts of the compound, and 5 parts of the alcoholic carboxylate, 10 parts of the isomeric alkali, and 20 parts of the compound, and 20 parts of the compound. Part of the octoine surfactant and 40 parts of water.

[0052] The preparation method of the compound shown in the formula 1 of the present embodiment is the same as that of Example 1, and the difference is that the percentage of the first intermediate is added to 6%, and the viscosity of the compound according to the control structure formula 1 is 100,000 cp.

[0053] The preparation method of the erythrite yarn of the present embodiment is the same as that of Example 1, which is not described in detail herein.

Embodiment 3

[0055] A hydrocarbon yarn with a soft sucking agent, a mass of 20 parts, including 20 parts of the compound, 20 parts of the alcoholic carboxylate, and 20 parts of isomeric alcohol ether, 10 Part of the antineine surfactant and 60 parts of water.

[0056] The preparation method of the compound shown in the formula 1 of the present embodiment is the same as that of the first embodiment, and the different viscosity of the compound according to the third embodiment is 80000 cp.

[0057] The preparation method of the erythrite yarn of the present embodiment is the same as that of Example 1, which is not described in detail herein.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com