Low-viscosity and high-strength transparent dealcoholized organosilicon sealant and production method thereof

A high-strength, low-viscosity technology, applied in adhesives, polymer adhesive additives, adhesive additives, etc., can solve problems such as poor mechanical properties, poor reinforcement, inability to meet stress offset, sealing and shock absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

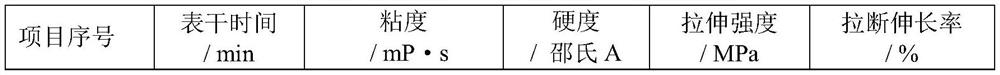

Examples

Embodiment 1

[0036] A low-viscosity, high-strength transparent dealcoholized silicone sealant, characterized in that: by weight, it includes the following components:

[0037] Alkoxy-terminated polydimethylsiloxane 100; Methoxy-modified silicone resin 10;

[0038] Methyl MQ silicone resin 10; Crosslinker 5;

[0039] Coupling agent 1; Composite catalyst 1;

[0040] The preparation method of methoxy-modified silicone resin in a low-viscosity, high-strength transparent dealcoholized silicone sealant component is as follows: add 100 parts of vinyl MQ silicone resin (the vinyl The vinyl content of MQ silicone resin is 1.32%), add toluene to dissolve, and slowly drop 5 parts of trimethoxysilane under rapid stirring at room temperature. Stir until evenly dispersed, vacuumize and inflate with nitrogen three times each, then add 0.05 parts of platinum catalyst dropwise, raise the temperature to 75°C and stir for 6 hours under the protection of nitrogen; transfer the obtained product to a round bo...

Embodiment 2

[0044] A low-viscosity, high-strength transparent dealcoholized silicone sealant, characterized in that: by weight, it includes the following components:

[0045] Alkoxy-terminated polydimethylsiloxane 100; Methoxy-modified silicone resin 15;

[0046] Methyl MQ silicone resin 20; Crosslinker 8;

[0047] Coupling agent 1.5; Compound catalyst 1.2;

[0048] The preparation method of methoxy-modified silicone resin in a low-viscosity, high-strength transparent dealcoholized silicone sealant component is as follows: add 100 parts of vinyl MQ silicone resin (the vinyl The vinyl content of MQ silicone resin is 1.82%), add toluene to dissolve, and slowly drop 7 parts of trimethoxysilane under rapid stirring at room temperature. Stir until evenly dispersed, vacuumize and inflate with nitrogen three times, then add 0.08 parts of platinum catalyst dropwise, raise the temperature to 70°C under nitrogen protection and stir for 4 hours; transfer the obtained product to a round bottom flas...

Embodiment 3

[0052] A low-viscosity, high-strength transparent dealcoholized silicone sealant, characterized in that: by weight, it includes the following components:

[0053] Alkoxy-terminated polydimethylsiloxane 100; Methoxy-modified silicone resin 25;

[0054] Methyl MQ silicone resin 25; Crosslinker 6;

[0055] Coupling agent 1.5; Compound catalyst 0.8;

[0056] The preparation method of methoxy-modified silicone resin in a low-viscosity, high-strength transparent dealcoholized silicone sealant component is as follows: add 100 parts of vinyl MQ silicone resin (the vinyl The MQ silicone resin has a vinyl content of 1.82%), was dissolved by adding toluene, and slowly dropped into 6 parts of trimethoxysilane under the state of rapid stirring at room temperature. Stir until evenly dispersed, vacuumize and inflate with nitrogen three times, then add 0.06 parts of platinum catalyst dropwise, raise the temperature to 55°C and stir for 8 hours under the protection of nitrogen; return to roo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com