Application of organosilicon material in 3D printing

A 3D printing and 3D printer technology, which is applied in the application field of silicone materials in 3D printing, can solve the problems of poor tensile strength and elongation at break of silicone rubber, and achieve high thermal curing elongation at break and high strength , the effect of improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

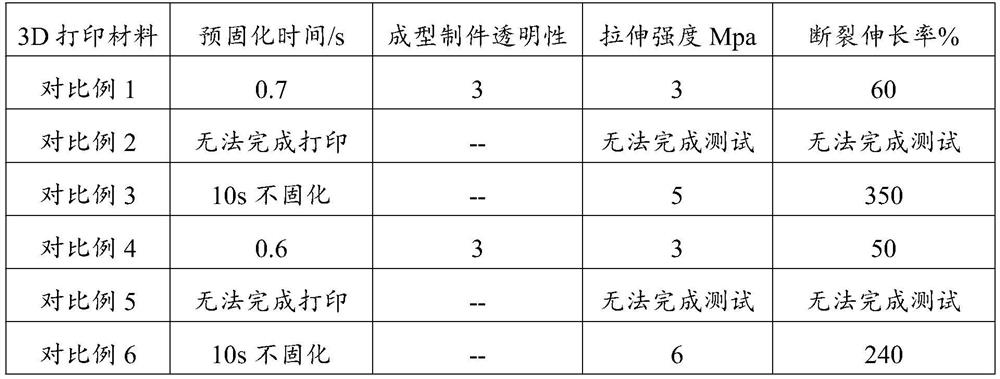

Examples

Embodiment 1

[0033] An application of an organosilicon material in 3D printing, wherein the organosilicon material is composed of the following components: 100g of dimethylvinylsiloxy-terminated dimethylpolysiloxane with a viscosity of 20000cps, 10g of Trimethylsiloxy terminated methyl hydrogen polysiloxane, 10g Jiangxi Xinjiayi XJY-8206N, 0.01g Lumogen (TM) IR788, 0.2 g 3-methyl-1-butyn-3-ol, 10 ppm chloroplatinic acid isopropanol solution (calculated as Pt metal, based on the mass of the total silicone material), 5 g fumed silica.

[0034] The preparation process of the above-mentioned organosilicon material is: (1) mixing and stirring the above-mentioned materials except for the isopropanol solution of chloroplatinic acid; (2) adding the alcohol solution of chloroplatinic acid to the mixture obtained in (1), stirring and mixing Uniform, you can get a transparent light-cured 3D printing material.

[0035] The preservation method of the organosilicon material prepared by the present inve...

Embodiment 2

[0037] An application of an organosilicon material in 3D printing, wherein the organosilicon material is composed of the following components: 50g dimethylvinylsiloxy-terminated dimethylpolysiloxane, 50g dimethylvinyl Siloxy-terminated dimethylsiloxane and methylphenylsiloxane copolymer, 20g methyl hydrogen-containing polysiloxane, 20g Shandong Dayi DY-VMQ102, 0.01g (methylcyclopentadiene ) manganese tricarbonyl, 0.2g 1-ethynyl cyclohexanol, 10ppm Shanghai Sibao ACS-Pt-30 (calculated as Pt metal, based on the total gel mass), 30g calcium carbonate.

[0038] The preparation process of the above-mentioned organosilicon material is the same as that in Example 1.

Embodiment 3

[0040] An application of an organosilicon material in 3D printing, wherein the organosilicon material is composed of the following components: 100g of dimethylvinylsiloxy-terminated dimethylsiloxane and methylvinylsiloxane Copolymer, 10g methylphenylhydrogenpolysiloxane, 5g methylhydrogenpolysiloxane, 5g Jiangxi Xinjiayi XJY-8206N, 5g Shandong Dayi DY-VMQ102, 0.01g Lumogen (TM) IR788, 0.2g 1-ethynyl cyclohexanol, 10ppm chloroplatinic acid isopropanol solution (calculated as Pt metal, based on the total colloid mass), 5g precipitated silica, 5g fumed silica.

[0041] The preparation process of the above-mentioned organosilicon material is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com