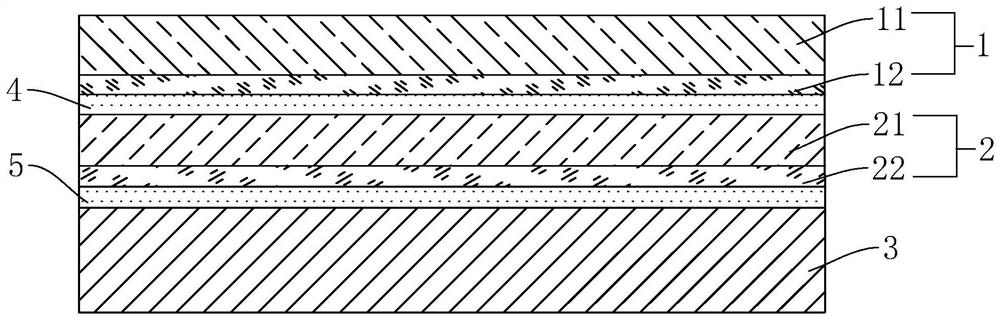

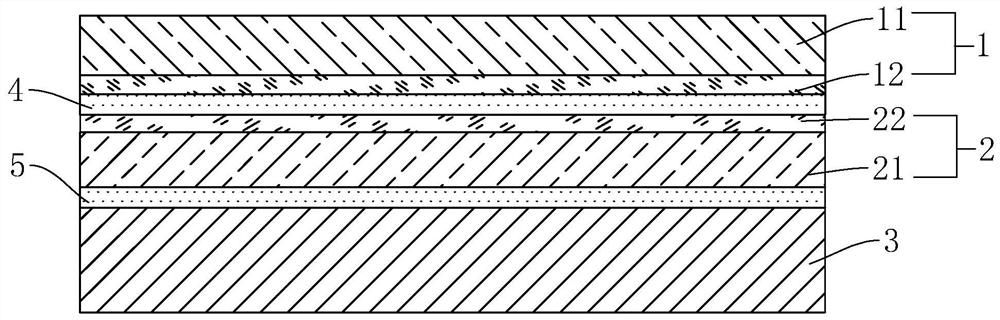

High-barrier aluminized composite film and preparation method thereof

An aluminized composite film and high-barrier technology, applied in the field of packaging materials, can solve problems such as exacerbating the transfer of aluminized layers, and achieve the effects of improving interlayer peel strength, good heat sealing performance and mechanical strength, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1- preparation example 7

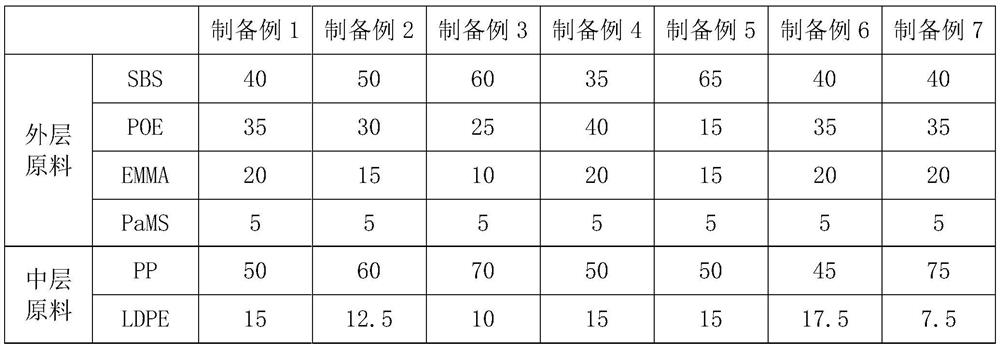

[0047] The difference between Preparation Examples 1-7 lies in the difference in raw materials, and the raw materials are shown in Table 1, and Preparation Example 1 is taken as an example below for illustration.

[0048] The preparation method of the PE film that preparation example 1 provides comprises the steps:

[0049] Mixing: After blending the outer layer raw materials, middle layer raw materials and inner layer raw materials respectively, put them into the three-layer co-extrusion casting machine;

[0050] Melting: heat the three-layer co-extrusion casting machine in sections, the temperature of the first stage is 165°C, the temperature of the second stage is 190°C, the temperature of the third stage is 220°C, and the temperature of the die head is 225°C; After the heads meet, they are extruded through the die lip;

[0051] Casting: Set the temperature of the casting roll to 25°C, and under the condition of a vacuum pressure of 0.8mbar, the extruded material is quench...

preparation example 8

[0056] The difference between this preparation example and preparation example 1 is that the thickness ratio of the outer layer, middle layer and inner layer of the PE film is 2:6:2.

preparation example 9

[0058] The difference between this preparation example and preparation example 1 is that the thickness ratio of the outer layer, middle layer and inner layer of the PE film is 1:6:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com