Tubular high-temperature solid oxide oxygen permeation membrane and preparation method thereof

A high-temperature solid and oxygen-permeable film technology, applied in the direction of oxygen preparation, oxygen/ozone/oxide/hydroxide, chemical instruments and methods, etc., can solve complex problems, achieve low power consumption, good safety, reduce Effect of Connector Cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

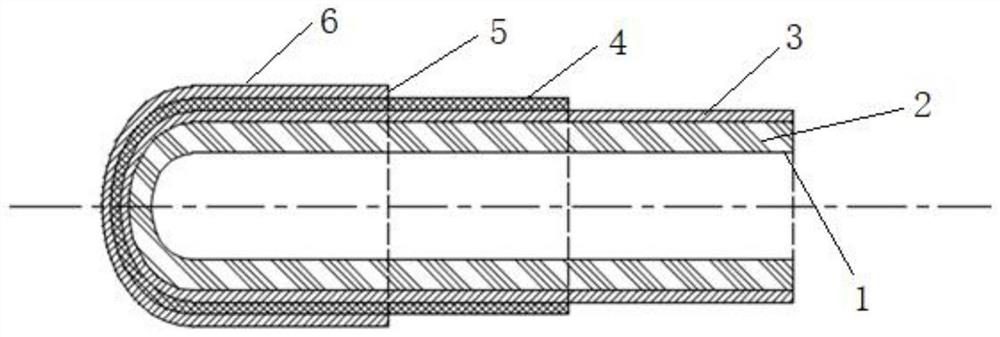

[0048] The preparation method of the solid oxide high-temperature oxygen-permeable membrane of the present invention comprises:

[0049] 1) Mix the porous support layer component powder, pore-forming agent, organic solvent, dispersant, polymer binder, and plasticizer by ball milling and then vacuumize to obtain the porous support layer slurry; the porous oxygen-permeable film layer Component powder, pore forming agent, organic solvent, dispersant, polymer binder, and plasticizer are ball-milled and mixed evenly, and then vacuumized to obtain a porous oxygen-permeable membrane layer slurry. The dense oxygen-permeable film layer component powder, pore-forming agent, organic solvent, dispersant, polymer binder, and plasticizer are ball-milled and mixed evenly, and then vacuumized to obtain a dense oxygen-permeable film layer slurry;

[0050] 2) The porous support layer slurry is prepared on a paraffin-coated glass tube by dipping-pulling process, and the support body reaches the ...

Embodiment 1

[0062] The large-area tubular high-temperature solid oxide oxygen permeable membrane is prepared by dipping-pulling method. The preparation process includes:

[0063] (1) Add pore-forming agent, organic solvent, dispersant, binder and plasticizer to the material powder of each functional layer, and fully mix by ball milling. Among them, the viscous porous support layer 2 slurry was ball milled for 3.5 hours under the condition of 400r / min, and the ball-to-material ratio was 1:2. The other functional layer slurries were ball milled for 48 hours at 100r / min, with a ball-to-material ratio of 1:1, so that the components could be fully dispersed. After the slurry is ball milled, filter it with an 80-mesh screen to remove the incompletely dissolved binder slag, and then vacuumize it under the condition of -0.1MPa to extract the air bubbles mixed in the slurry;

[0064] (2) The environment for the impregnation-lifting process requires indoor relative humidity <50%, and a temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com