Aggregate particle size and particle shape automatic detection device and system thereof

An automatic detection device and particle shape technology, applied in the field of aggregates, can solve the problems of unreasonable control of feeding amount, inaccurate data of particle quantity, particle size, particle shape, gradation and fineness modulus, etc. , to achieve the effect of guaranteeing data accuracy, guaranteeing simplicity and guaranteeing the dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

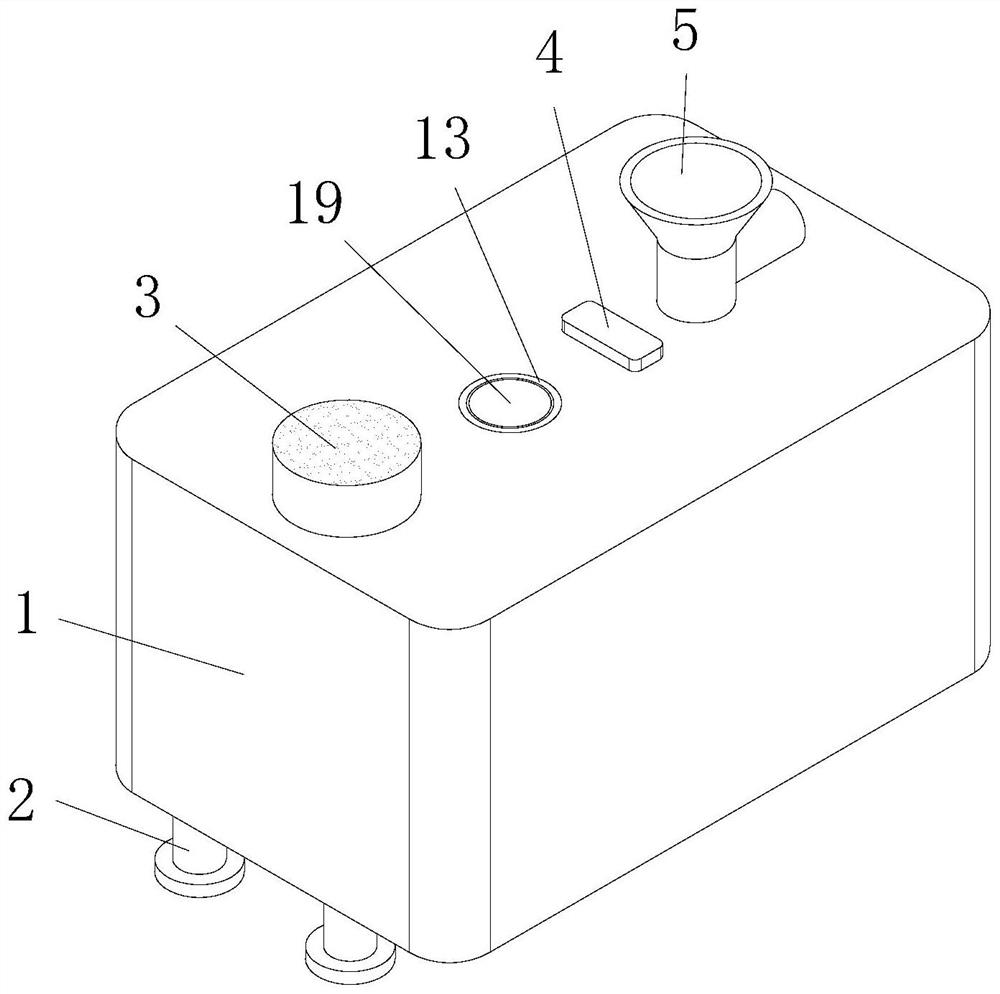

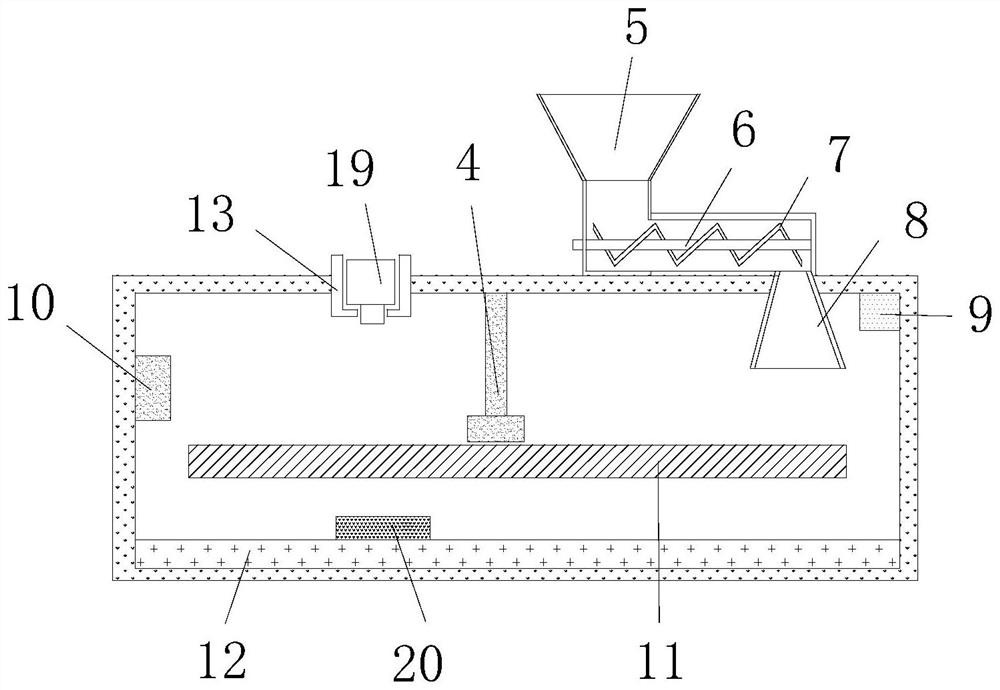

[0039] see Figure 1-3, the present invention provides a technical solution: an automatic detection device for aggregate particle size and shape, comprising a chassis 1, the lower side of the chassis 1 is threadedly connected with an adjustment foot 2, the upper side of the chassis 1 is fixedly connected with a level 3, and the chassis 1 The inside of the cabinet 1 is fixedly connected with a cleaning air hole plate 4, the upper side of the cabinet 1 is fixedly connected with a hopper 5, the inside of the hopper 5 is rotatably connected with a rotating shaft 6, the surface of the rotating shaft 6 is fixedly connected with a feeding shaft 7, and the surface of the feeding shaft 7 The shape is spiral, and the inside of the cabinet 1 is fixedly connected with a dispersing mechanism 8 that communicates with the inside of the hopper 5. When the rotating shaft 6 on the inner wall of the hopper 5 is controlled to rotate by using an external control mechanism, when the rotating speed o...

Embodiment 2

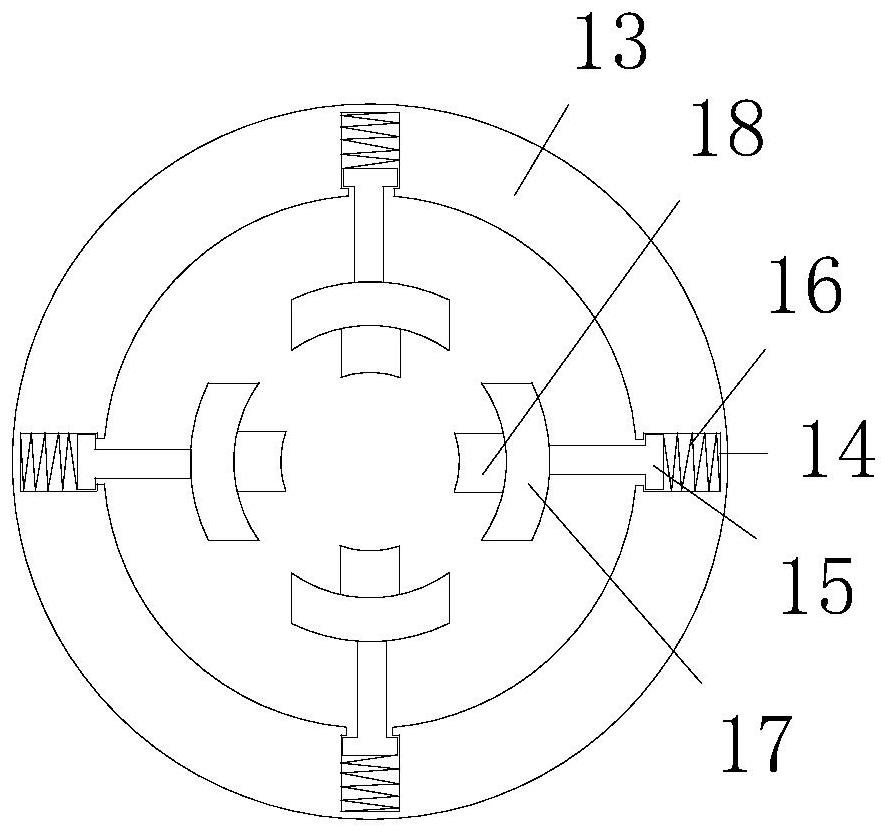

[0042] see Figure 1-3 , On the basis of Embodiment 1, a fixing device is provided inside the cabinet 1, the fixing device includes a fixed outer plate 13, the surface of the fixed outer plate 13 is fixedly connected to the inside of the cabinet 1, and a camera 19 is arranged inside the fixed outer plate 13, The camera 19 is located directly above the supplementary light 20, and the supplementary light 20 is located directly below the camera 19 to ensure that the transparent circular turntable 11 is illuminated more clearly. The inner side of the fixed outer plate 13 is provided with a chute 14, and the inner wall of the chute 14 Slidingly connected with slide plate 15, the right side of slide plate 15 is fixedly connected with fixed spring 16, and the right end of fixed spring 16 is fixedly connected with the inner wall of chute 14, and the left side of slide plate 15 is fixedly connected with fixed inner plate 17, and the fixed inner plate 17 The left side is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com