Fault modeling method for electro-hydraulic actuator of gas turbine

An electro-hydraulic actuator, fault modeling technology, applied in mechanical equipment, servo meter circuit, design optimization/simulation, etc., can solve the problem of gas turbine control system fault diagnosis theory research and engineering application, hydraulic control system, simulation has not been applied Problems such as insufficient curve description, to achieve the effect of intuitive fault diagnosis, high practical value, and high degree of compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The present invention will be further described in detail below in conjunction with the accompanying drawings.

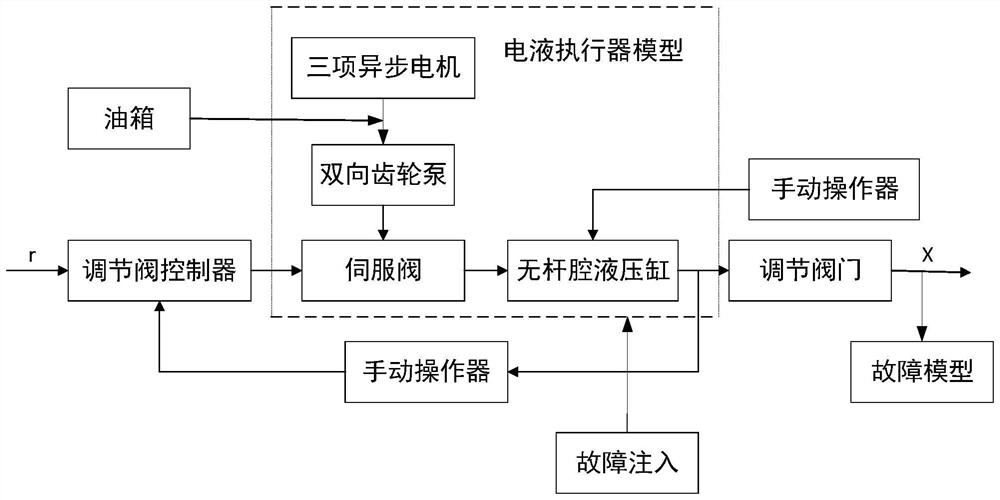

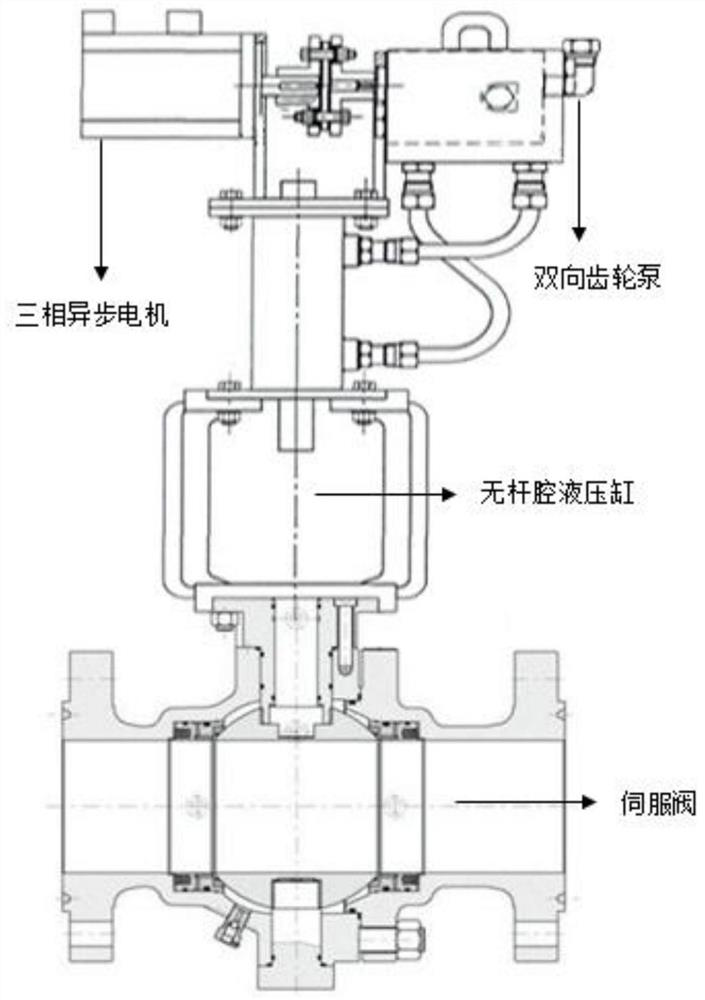

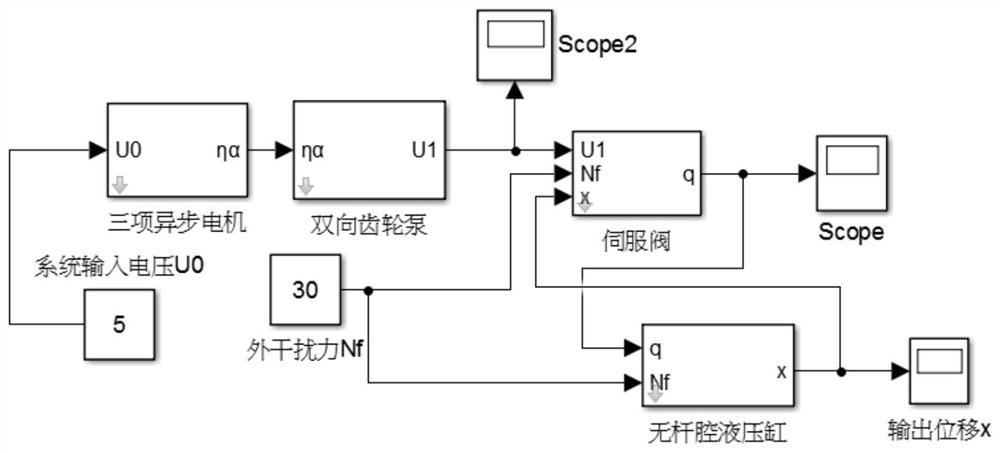

[0068] Such as figure 1 The shown embodiment of the present invention establishes the normal mechanism model and fault model of the gas turbine electro-hydraulic actuator through the working principle and method of the electro-hydraulic actuator, and performs fault injection simulation under the semi-physical experiment platform; wherein the electro-hydraulic actuator model Including three-phase asynchronous motor, bidirectional gear pump, rodless chamber hydraulic cylinder, servo valve; complete the construction of the overall model, and realize the simulation of typical faults by setting and changing parameters.

[0069] The fault modeling method of this embodiment specifically includes the following steps:

[0070] Step 1. Determine the initial state of the electro-hydraulic actuator and the electromagnetic torque signal η output by the three-phase asynch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com