Embossing and cutting device for aluminum-foil paper material processing

A material processing and aluminum foil paper technology, applied in the field of aluminum foil paper processing equipment, can solve the problems of poor cooling effect and complex cooling mechanism structure, and achieve the effect of good embossing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments.

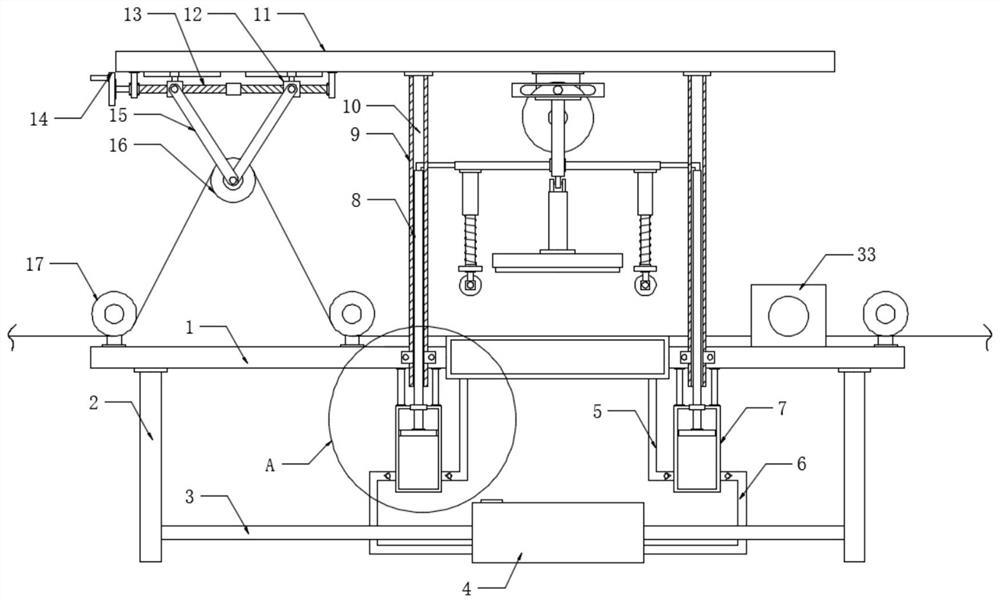

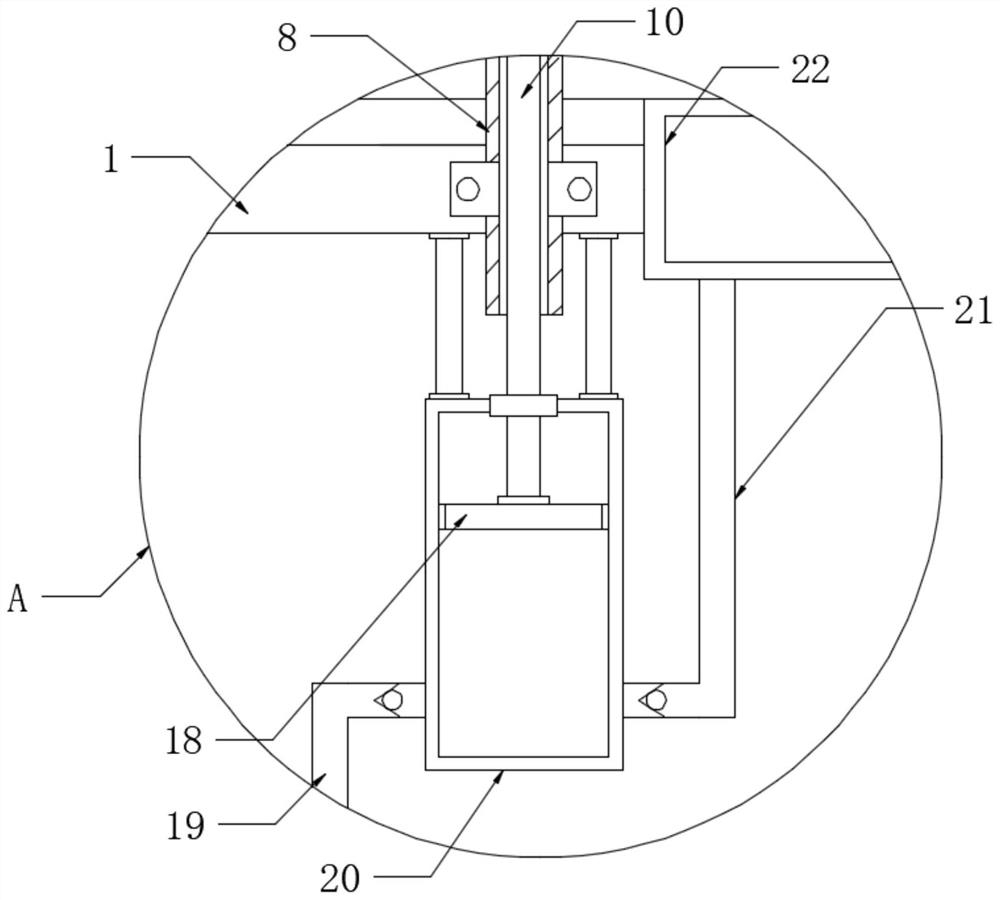

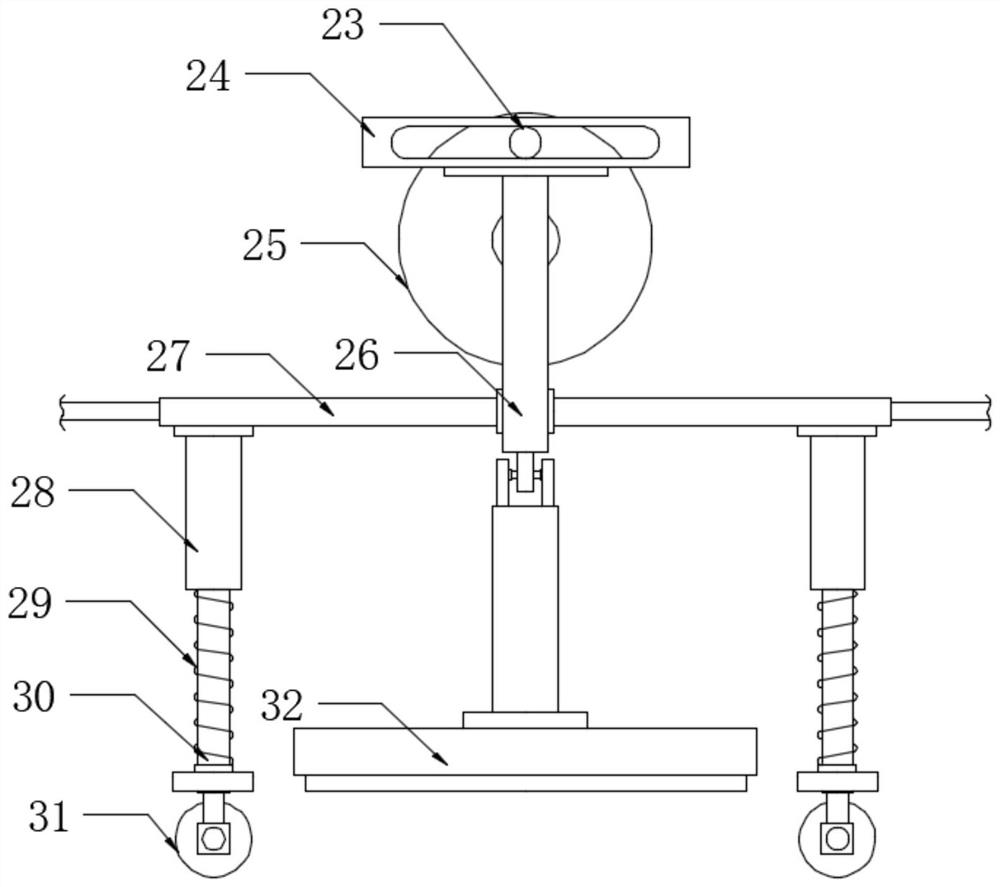

[0025] see Figure 1-3 , an embossing and cutting device for aluminum foil paper material processing, including a support base 1, a conveying assembly, an embossing assembly, and a cooling assembly, the conveying assembly includes multiple sets of conveying rollers 17 and tension rollers 16 arranged on the surface of the supporting base 1 , the conveying roller 17 and the tensioning roller 16 are used to convey the aluminum foil paper wound on the surface, the embossing assembly includes an embossing plate 32 and a lifting part, and the lifting part is fixedly connected with the embossing plate. The embossing plate 32 is driven back and forth toward and away from the aluminum foil paper to emboss the aluminum foil paper. The cooling assembly includes a cooling box 22 arranged between the support bases 1. The cooling box 22 passes through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com