Strip-shaped steel shape corrector

A straightener and steel technology, which is applied in the field of strip steel shape straighteners, can solve problems such as inaccurate straightening, and achieve the effect of avoiding the increase of errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

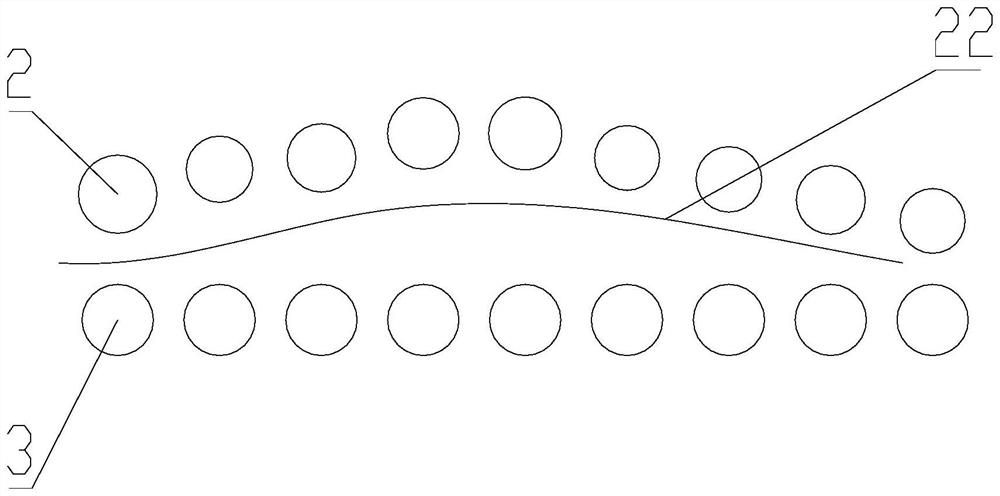

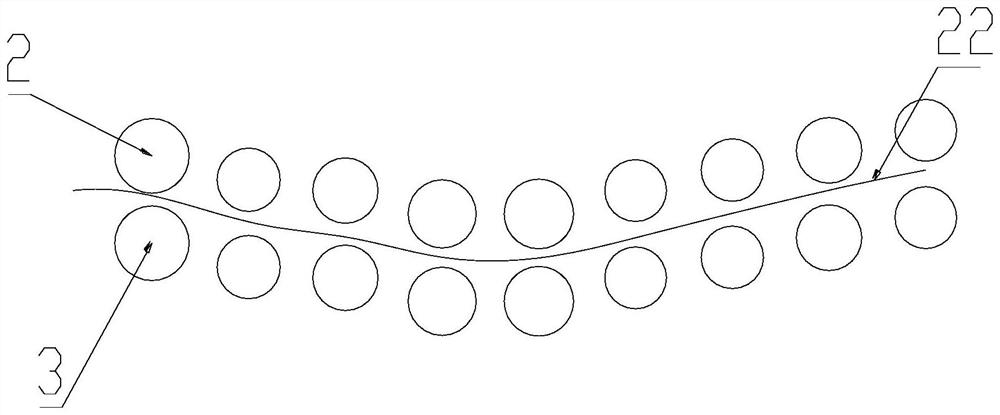

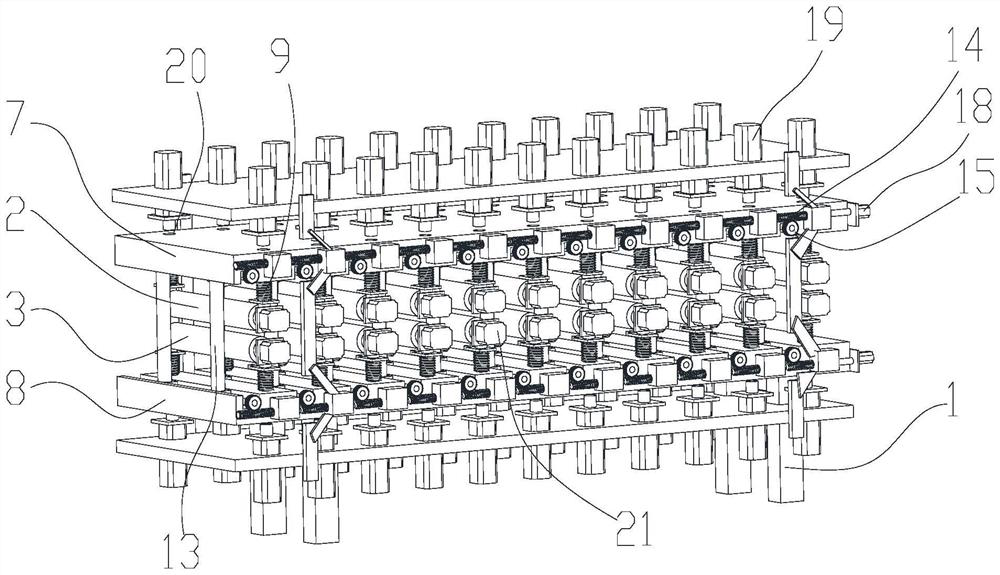

[0022] see Figure 1-5 , a strip-shaped steel shape corrector, comprising a frame 1, the frame 1 is provided with several upper rollers 2, several lower rollers 3, several extruding mechanisms, several laser rangefinders 4, and a single-chip microcomputer 5, the The upper roll 2 is located directly above the lower roll 3, the upper roll 2 and the lower roll 3 are parallel to each other, and the roll holders 10 of the upper roll 2 and the lower roll 3 are connected to the frame 1 through the slide bar 6 respectively. The top plate 7 and the bottom plate 8 are slidingly connected, the slide bar 6 is sleeved with a spring 9, the roller seat 10 of the upper roller 2 is provided with a laser rangefinder 4 on the side facing the top plate 7, and the lower roller 3 A laser range finder 4 is arranged on the side of the roller base 10 facing the bottom plate 8, and the side of the top plate 7 facing away from the roll base 10 and the side of the bottom plate 8 facing away from the roll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com