A Conveying Device Based on Magnetic Constraint to Hold the Ring-shaped Opening of Socks

A conveying device and magnetic restraint technology, which is applied in the direction of conveyors, transportation and packaging, etc., can solve the problems of difficult opening of socks and low production efficiency of socks, and achieve the effect of improving production efficiency, reducing labor intensity and reducing operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

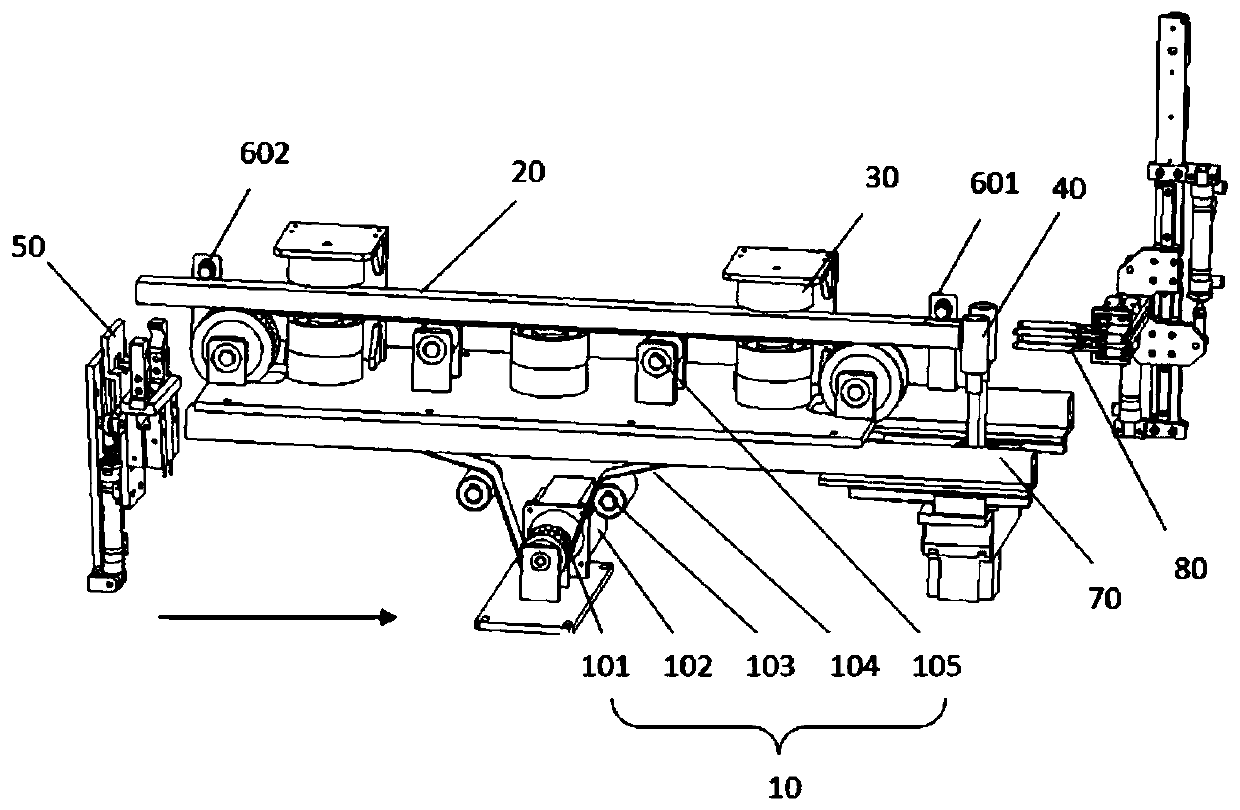

[0038] Such as figure 1 As shown, a conveying device based on magnetic constraints to maintain the annular opening of the sock tube according to the embodiment of the present invention: includes a sock feeding mechanism 10, a sock tube assembly 20, an electromagnet 30, a limit mechanism 40, a sock tube clamping mechanism 50, Detect the sensor 60 and the bracket 70; the sock feeding mechanism 10 is fixed on the bracket 70.

[0039] The sock feeding mechanism 10 includes: a first motor 102 , a conveyor belt 104 , a pulley 101 , a tension pulley 103 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com