Method for increasing value of carbon dioxide photocatalytic reduction process

A photocatalysis and catalyst technology, applied in the field of solar energy utilization, can solve the problems of low industrial value and low efficiency, and achieve the effect of improving the conversion rate of CO2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

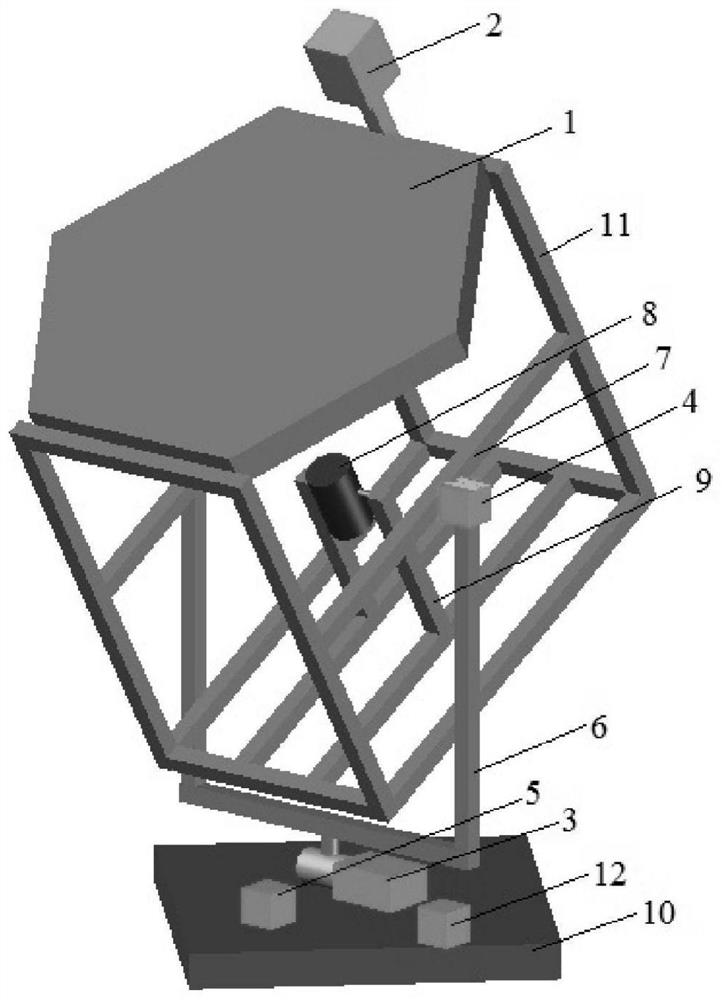

Image

Examples

Embodiment 1

[0029] Preparation of Example 1 Supported Copper Cluster Catalyst

[0030] (1) Preparation of TiO 2 Nanotube array, comprising the steps of:

[0031] Electrolyte preparation: 0.3g NH 4 F, 2ml H 2 O was dissolved in 100ml ethylene glycol and poured into a 200ml plastic beaker with a stirrer to form an electrolyte.

[0032] Electrode preparation: The metal titanium sheet was trimmed to form a disc with a diameter of 2 cm, and the surface of the titanium sheet was polished with 7000-grit sandpaper to remove the surface oxidized part. Ultrasonic clean the polished titanium sheet in 10ml of absolute ethanol for 15 minutes, continue to ultrasonically clean it in acetone for 15 minutes, after the ultrasonic wave is completed, wash it with deionized water for 3 to 5 times, and put it in ethanol for later use to avoid oxidation.

[0033] Prepare the polishing solution: the composition of the polishing solution is: 10ml H 2 O, 5ml HNO 3 , 3ml H 2 o 2 , 1ml 18% (NH 2 ) 2 CO solut...

Embodiment 2

[0041] Embodiment 2 Non-concentrating operation

[0042] The concentrating mirror on the concentrating reaction system was removed, and the performance of the copper cluster catalyst loaded under non-concentrating conditions was measured for comparison. Clean the photocatalytic reactor and dry it in an oven; insert a thermocouple into the reactor to monitor the temperature change; secondly, place the prepared supported copper cluster catalyst with a loading capacity of 10% on the catalyst tray Add 2 mL of deionized water, seal the reactor well, and use a vacuum pump to pump out the air in the reactor, and then pass in nitrogen (99%) to purge and remove impurity gases. 2 The gas is filled into the reactor (filling volume: 0.1MP), and finally the reactor is placed on the light concentration reaction system, and the switch is turned on. The solar biaxial tracking system adjusts and irradiates the sunlight on the light incident window of the reactor, and starts reaction. Samples...

Embodiment 3

[0043] The chemical chain reaction under the concentrating condition of embodiment 3 (using a kind of classic catalyst P25 as contrast)

[0044] The chemical chain reaction is realized under light-gathering conditions, first by conventional CO 2 Preparation of methane and CO by photocatalytic reduction process 2 mixed composition. That is to say, the photocatalytic reactor is cleaned and dried in an oven; a thermocouple is inserted into the reactor to monitor the temperature change; secondly, P25 (standard TiO produced by Degussa, Germany) 2 Catalyst) photocatalyst placed on the catalyst tray, add 2mL deionized water, and then CO 2 The gas is filled into the reactor (filling amount: 0.1MP), and finally the reactor is placed on the light concentrating reaction system, and the sunlight is gathered by the light concentrating system (the concentration ratio is 200, and the temperature reaches 300°C) and irradiated on the On the light incident window of the reactor, the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com