Gas diffusion layer structure of electrochemical oxygen generator membrane electrode and preparation method

A gas diffusion layer and oxygen generator technology, which is applied to electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of reduced anode water electrolysis reaction rate, insufficient water molecules, shortened service life of electrochemical oxygen generators, etc. Gas diffusion performance and water management performance, optimization of water vapor distribution performance, effect of reducing proton conduction resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

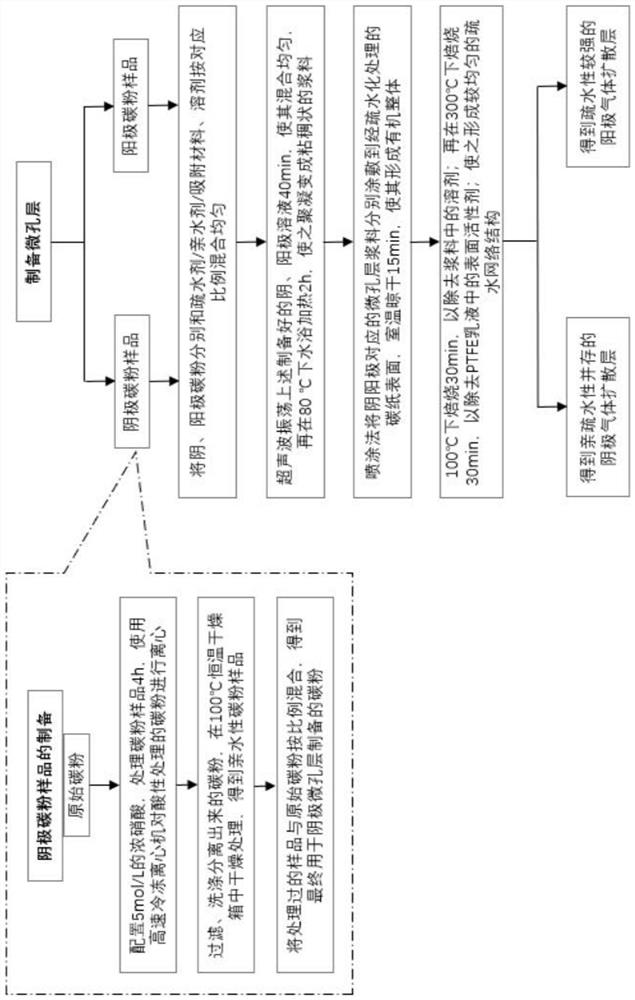

[0026] The invention also relates to a method for preparing a gas diffusion layer structure of an electrochemical oxygen generator membrane electrode, combining figure 1 and figure 2 As shown, it includes the following steps:

[0027] Step S1, using carbon powder, PTFE hydrophobic agent and solvent to prepare anode microporous layer carbon powder slurry, using carbon powder, PTFE hydrophobic agent, hydrophilic agent, solvent and adsorption material to prepare cathode microporous layer carbon powder slurry, said The solvent is deionized water, glycerin or a mixture of the two;

[0028] Step S2, uniformly apply the carbon powder slurry of the anode microporous layer and the carbon powder slurry of the cathode microporous layer to the surface of the base layer after hydrophobization treatment, and dry at room temperature for 5 minutes to 15 minutes, and then dry it at 80 to 120 Heat treatment at ℃ for 10min~30min, and then at 300~400℃ for 20min~60min.

[0029]Further, in the ...

Embodiment 1

[0040] This example provides a method for preparing a cathode and anode with different hydrophilic and hydrophobic microporous layer structures, wherein the different hydrophilic and hydrophobic microporous layer structures are to meet the oxygen production performance of the electrochemical oxygen generator, and carbon fiber paper is used as the conductive porous base layer. Microporous layers with different hydrophilicity and hydrophobicity are prepared on the surface, and the hydrophilicity and hydrophobicity are mainly reflected in the preparation method of carbon powder and the mass ratio of carbon powder and hydrophobic agent.

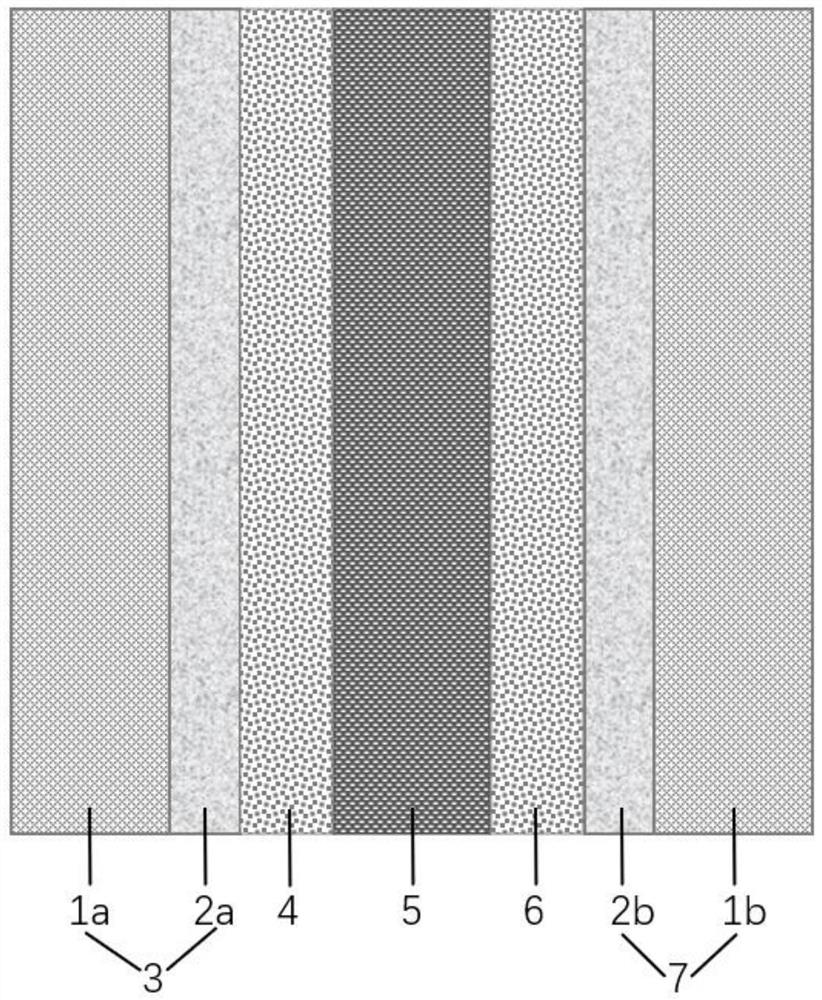

[0041] See figure 1 , figure 1 It is a structural diagram of the membrane electrode assembly of a proton exchange membrane electrochemical oxygen generator, which includes a cathode gas diffusion layer 3 , a cathode catalytic layer 4 , a proton exchange membrane 5 , an anode catalytic layer 6 , and an anode gas diffusion layer 7 . The cathode ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com