Photocuring PET coating and preparation method thereof, and preparation method and application of PET base material

A light-curing and coating technology, which is applied in the direction of coatings, film/sheet adhesives, adhesives, etc., can solve the problems of mold restrictions, poor durability, and high thermoplasticity, so as to improve compactness and strength. The effect of strong scraping and low resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

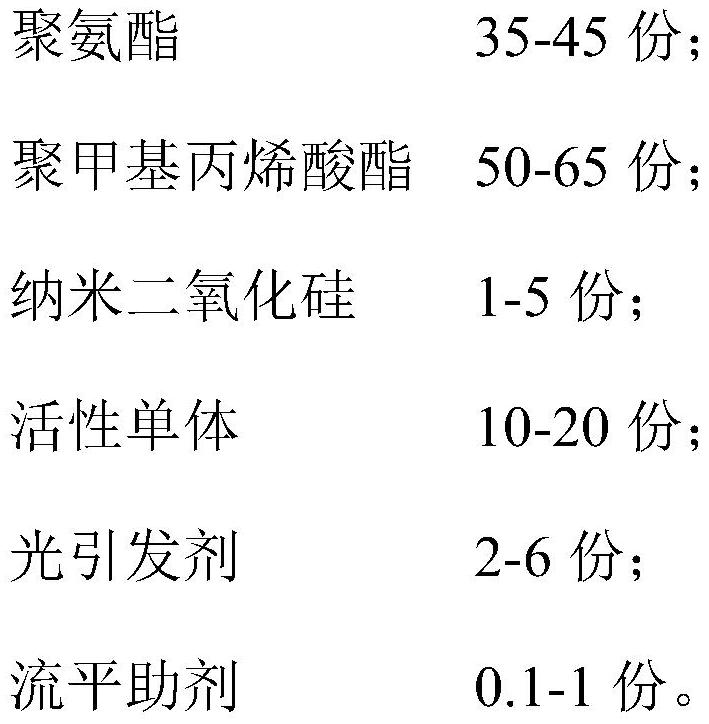

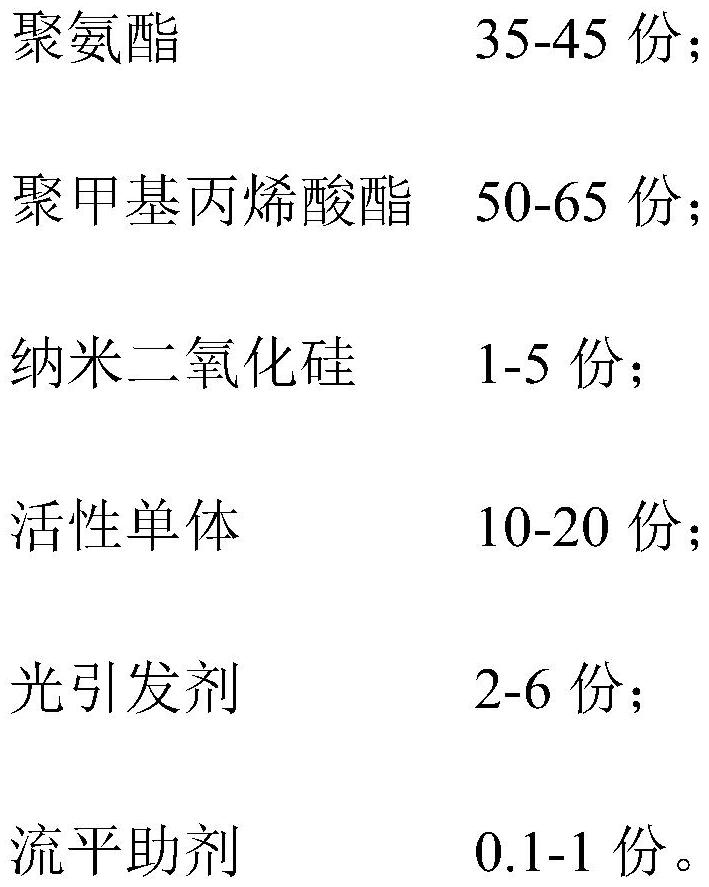

[0050] A light-cured PET coating, comprising the following components in parts by mass:

[0051]

[0052] As a further embodiment, the active monomer is isobornyl acrylate;

[0053] The polymethacrylate is methyl methacrylate;

[0054] The particle diameter of described nano silicon dioxide is 5nm;

[0055] The photoinitiator is preferably a photoinitiator IRGACURE184 from BASF, Germany.

[0056] The leveling aid is preferably YK-UV 3500 from BYK, Germany.

[0057] The preparation method of described light-cured PET paint, comprises the following steps:

[0058] S1: After mixing urethane and methacrylate according to the formula, heat and stir, the temperature is 115°C, the pressure is 1.1MPa, and nitrogen is poured into it for protection for 1.2h, then the pressure is released to be consistent with the indoor air pressure, and the temperature is lowered to 40 After ℃, obtain the first mixture, standby;

[0059] S2: Mix and stir silicon dioxide and an appropriate amoun...

Embodiment 2

[0063] A preparation method for light-cured PET substrate, comprising the following steps:

[0064] 1) Coating the photocurable PET coating of Example 1 on the bottom film to obtain a photocurable PET coating; the coating adopts the method of straight scraping coating, the angle of the scraper is 58°, and the thickness is 100 μm;

[0065] 2) drying the photocured PET coating, and then irradiating it with UV light, the wavelength of the UV light is 365nm, and the irradiation energy is 15MJ / cm 2 , to obtain a light-cured PET base material, and protect the roll material with an opaque aluminum foil to avoid storage and contact with ultraviolet rays; The drying temperature is 95°C, the drying temperature of the third stage is 125°C, the drying temperature of the fourth stage is 95°C, the drying temperature of the fifth stage is 85°C, and the drying time of each stage is 2 minutes.

[0066] Apply the above-mentioned light-cured PET substrate to the protective film of the curved sc...

Embodiment 3

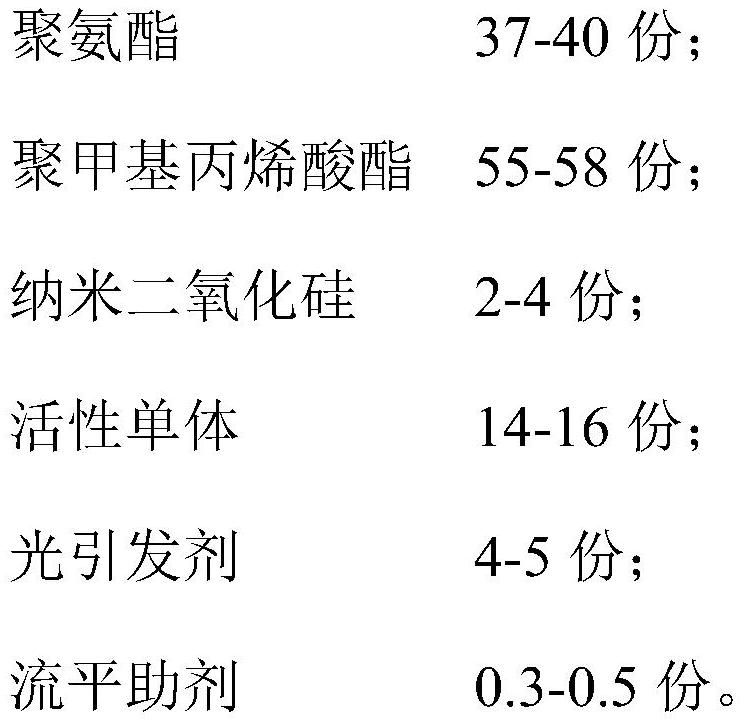

[0080] A light-cured PET coating, comprising the following components in parts by mass:

[0081]

[0082] Further, the active monomer is isobornyl acrylate;

[0083] The polymethacrylate is ethyl methacrylate;

[0084] The particle diameter of described nano silicon dioxide is 5nm;

[0085] The photoinitiator is preferably the photoinitiator Esacure KIP 150 from IGM Company.

[0086] The leveling aid is preferably a general-purpose wetting and dispersing agent TEGO Dispers 655 from German Tego Company.

[0087] The preparation method of described light-cured PET paint, comprises the following steps:

[0088] S1: After mixing urethane and methacrylate according to the formula, heat and stir at a temperature of 110°C and a pressure of 1.1MPa, and pour nitrogen into it for protection for 1.6h, then release the pressure until it is consistent with the indoor air pressure, and cool down to 40 After ℃, obtain the first mixture, standby;

[0089] S2: Mix and stir silicon diox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com