Preparation method of ceramic tile with ultra-matte effect

A light effect, ceramic tile technology, applied in the field of preparation of super matt effect ceramic tiles, can solve the problems of low gloss, complex process, unfavorable large-scale mass production, etc. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

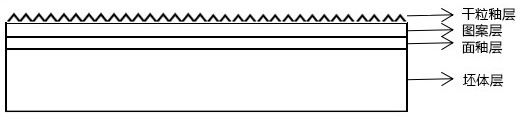

Image

Examples

preparation example Construction

[0026] A method for preparing ceramic tiles with a super-matte effect. The ceramic body can be prepared from known ceramic raw materials according to a conventional method, or can be made from the powder of the ceramic body defined in the application. For ceramic raw materials or ceramic bodies The powder of the body is subjected to steps such as ball milling, powder spraying and granulation, and compaction drying to prepare a ceramic green body; specifically, the ceramic raw materials used in the ceramic green body in the following examples include the following chemical components by weight percentage: Si0 2 : 67%, A1 2 o 3 : 21.5%, K 2 0: 3.5%, Na 2 0: 2%, MgO: 0.5%, CaO: 0.3%, Fe 2 o 3 IL: 0.5%, IL: 4.7%; the remaining 0.6% to 0.8% of the powder made of full-throwing brick body is passed through a 250-mesh sieve.

[0027]A method for preparing ceramic tiles with a super-matte effect. The coating method of the top glaze can be a bell jar or a glaze spray cabinet, or a...

Embodiment 1

[0034] A kind of preparation method of ultra-matt effect ceramic tile, the steps are as follows:

[0035] (1) Pressing of ordinary ceramic bodies.

[0036] (2) Kiln drying, the drying time is 50min, the temperature is 130-150℃, and the moisture content of the dried green body is within 0.3%.

[0037] (3) Apply surface glaze to the glaze spray cabinet, the specific gravity of the surface glaze is 1.45, and the amount of glaze is 450g / m2. The chemical composition of the surface glaze is: by mass, loss on ignition: 1.82%, SiO 2 : 53.14%, Al 2 o 3 : 32.04%, Fe 2 o 3 : 0.25%, TiO 2 : 0.13%, CaO: 0.42%, MgO: 0.35%, K 2 O: 2.29%, Na 2 O: 4.32%, ZrO 2 : 5.24%.

[0038] (4) Inkjet printing pattern. Print black designs with an average grayscale of 45%.

[0039] (5) Kiln drying, the drying temperature is 130-150°C, and the drying time is 60s.

[0040] (6) Spray dry granular glaze, specific gravity of dry granular glaze: 1.32, glaze amount: 250 g / m2, spray glaze cabinet, nozz...

Embodiment 2

[0049] A kind of preparation method of ultra-matt effect ceramic tile, the steps are as follows:

[0050] (1) Pressing of ordinary ceramic bodies.

[0051] (2) Kiln drying, the drying time is 50min, the temperature is 130-150℃, and the moisture content of the dried green body is within 0.3%.

[0052] (3) Apply surface glaze to the glaze spray cabinet, the specific gravity of the surface glaze is 1.45, and the amount of glaze is 450g / m2. The chemical composition of the surface glaze is: by mass, loss on ignition: 1.82%, SiO 2 : 53.14%, Al 2 o 3 : 32.04%, Fe 2 o 3 : 0.25%, TiO 2 : 0.13%, CaO: 0.42%, MgO: 0.35%, K 2 O: 2.29%, Na 2 O: 4.32%, ZrO 2 : 5.24%.

[0053] (4) Inkjet printing pattern. Print black designs with an average grayscale of 45%.

[0054] (5) Kiln drying, the drying temperature is 130-150°C, and the drying time is 60s.

[0055] (6) Spray dry granular glaze, specific gravity of dry granular glaze: 1.32, glaze amount: 200 g / m2, spray glaze cabinet, nozz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com