Rapid bending forming method for magnesium alloy pipe under assistance of pulse current

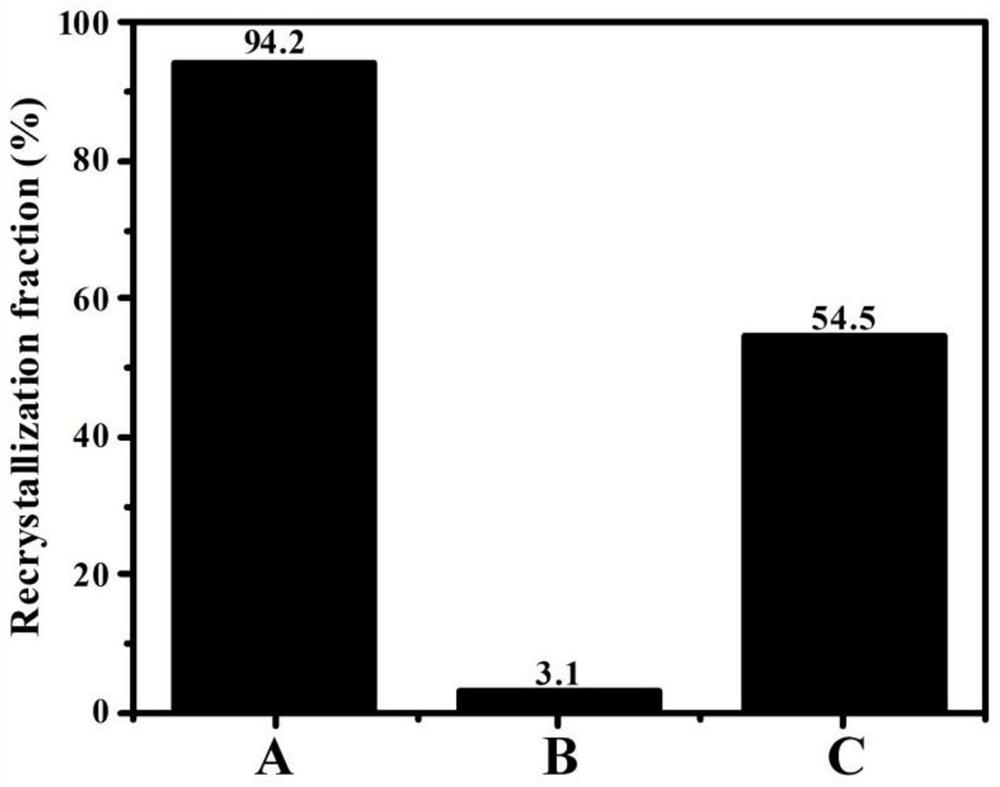

A pulse current and bending forming technology, which is applied in furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as low dimensional accuracy and obvious rebound phenomenon, so as to improve work efficiency, reduce costs and energy, and refine grains Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

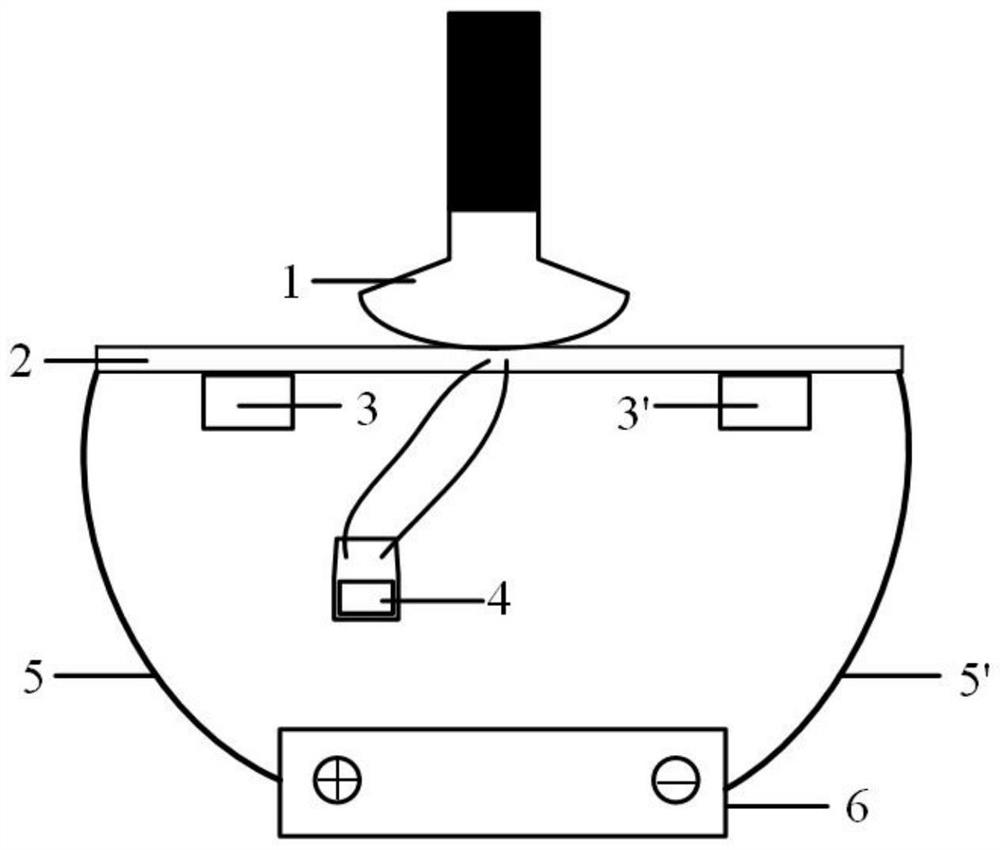

Method used

Image

Examples

Embodiment 1

[0029] A kind of pulse electric current assisted AZ61 magnesium alloy tube rapid bending forming method, comprises the steps:

[0030] (1) Homogenize the AZ61 magnesium alloy pipe, including: heat preservation at 400°C for 1 hour, and then quench with water at 30-40°C to obtain the homogenized magnesium alloy pipe;

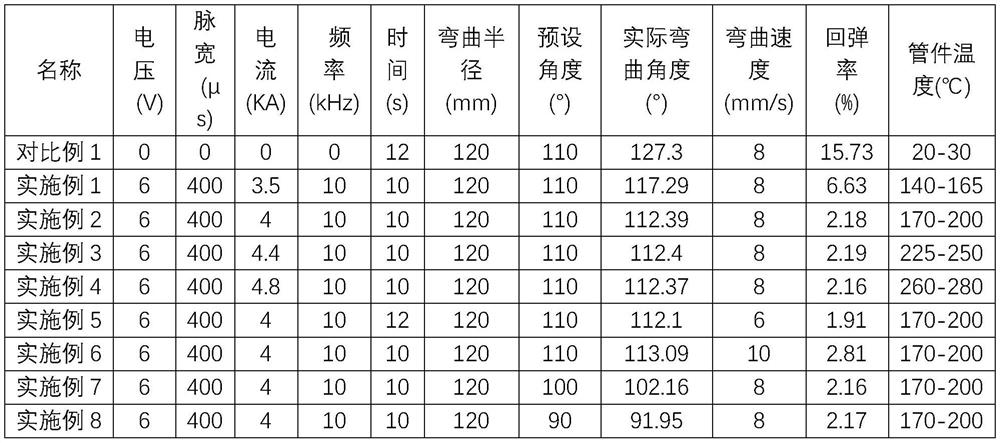

[0031](2) Fix the AZ61 magnesium alloy pipe material obtained in step (1) between the back-up roll and the bending die of the hydraulic pipe bender, connect the positive and negative poles of the pulse power supply at the symmetrical positions of the two ends of the pipe material, and feed in the current. Run the bending machine after the indication is stable. The bending radius is 120mm, the movement speed of the bending die is 8mm / s; the preset bending angle is 110.0°. The voltage is 6.0V, the current intensity is 3.5KA, the pulse width is 400μs, the frequency is 10.0kHz, the temperature of the deformation area is 140-165℃, and the time required for the process...

Embodiment 2

[0033] A kind of pulse electric current assisted AZ61 magnesium alloy tube rapid bending forming method, comprises the steps:

[0034] (1) Homogenize the magnesium alloy pipe, including: heat preservation at 400°C for 1 hour, and then quench with water at 30-40°C to obtain the homogenized magnesium alloy pipe;

[0035] (2) Fix the AZ61 magnesium alloy pipe material obtained in step (1) between the back-up roll and the bending die of the hydraulic pipe bender, connect the positive and negative poles of the pulse power supply at the symmetrical positions of the two ends of the pipe material, and feed in the current. Run the bending machine after the indication is stable. The bending radius is 120mm, the movement speed of the bending die is 8mm / s; the preset bending angle is 110.0°. The voltage is 6.0V, the current intensity is 4.0KA, the pulse width is 400μs, the frequency is 10.0kHz, the temperature of the deformation area is 170-200℃, and the time required for the process is ...

Embodiment 3

[0037] A kind of pulse electric current assisted AZ61 magnesium alloy tube rapid bending forming method, comprises the steps:

[0038] (1) Homogenize the magnesium alloy pipe, including: heat preservation at 400°C for 1 hour, and then quench with water at 30-40°C to obtain the homogenized magnesium alloy pipe;

[0039] (2) Fix the AZ61 magnesium alloy pipe material obtained in step (1) between the back-up roll and the bending die of the hydraulic pipe bender, connect the positive and negative poles of the pulse power supply at the symmetrical positions of the two ends of the pipe material, and feed in the current. Run the bending machine after the indication is stable. The bending radius is 120mm, the movement speed of the bending die is 8mm / s; the preset bending angle is 110.0°. The voltage is 6.0V, the current intensity is 4.4KA, the pulse width is 400μs, the frequency is 10.0kHz, the temperature of the deformation area is 225-250℃, and the time required for the process is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

| Bending angle | aaaaa | aaaaa |

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com