Working surface profile line of a U-forming machine mold and its generation method

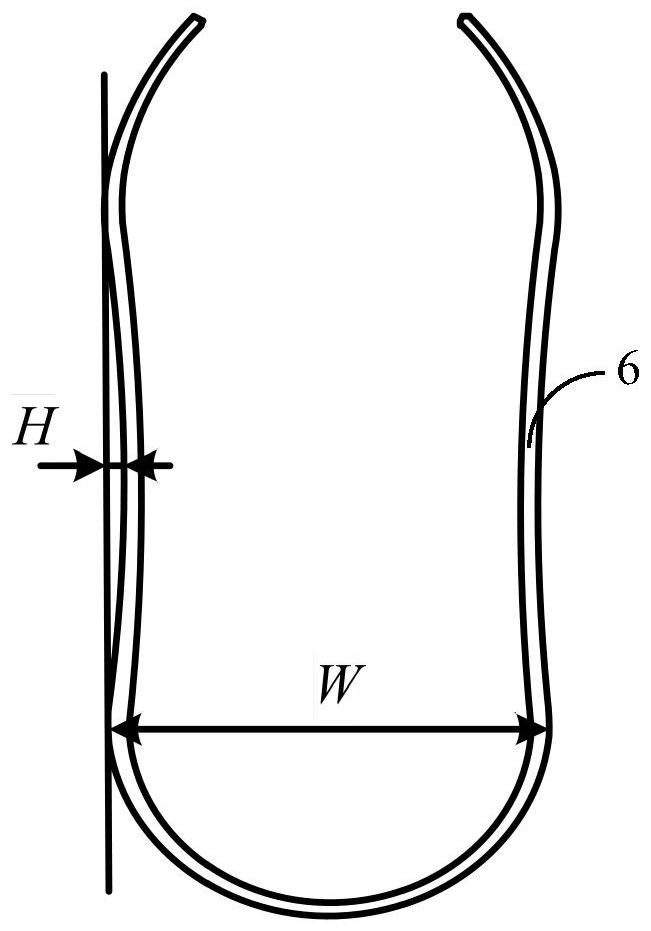

A forming machine and working surface technology, applied in the field of steel pipe manufacturing, can solve problems such as out-of-roundness exceeding the standard, indentation on the surface of the steel plate, and the side wall depression H of the U-shaped cylinder 6 exceeding the standard, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below, the structure and working principle of the present invention will be further described in conjunction with the accompanying drawings.

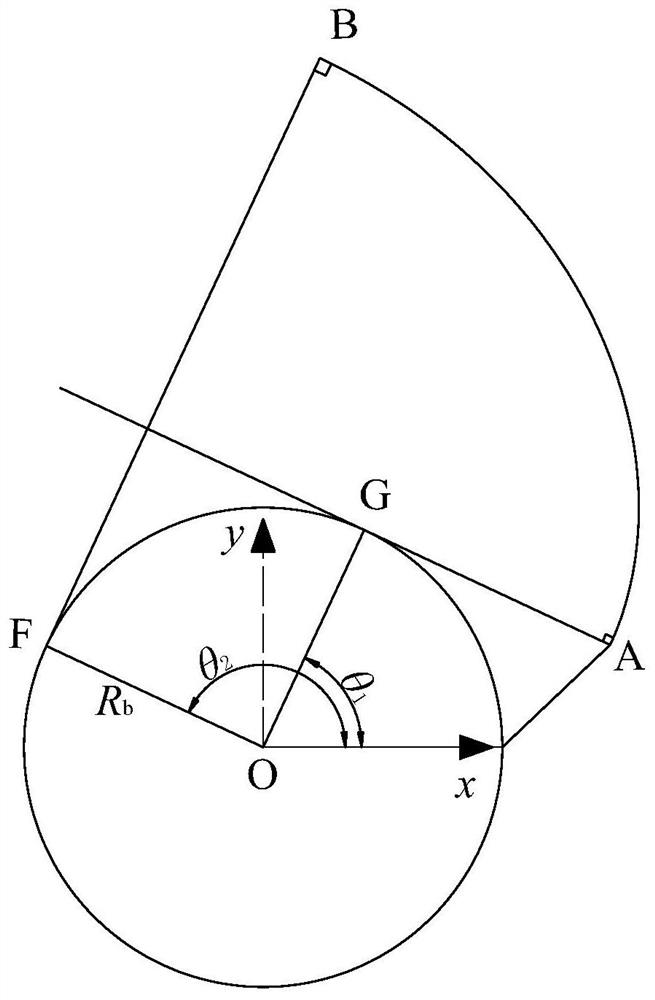

[0026] see figure 2 , the profile line of the working surface of the mold of the U forming machine of the present invention is symmetrical about the center line BF, and the profile line on one side of the center line BF includes an involute segment BA and an arc segment AC, and the involute segment BA and the arc segment AC are smoothly connected , that is, the radius of curvature at the junction point A of the two is the same; correspondingly, the profile line on the other side of the center line BF includes the involute segment BD and the arc segment DE, and the involute segment BD and the arc segment DE are smoothly connected, that is The radius of curvature at the junction point D of the two is the same.

[0027] see image 3 , establish a Cartesian coordinate system with the center O of the base circle as the origin, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com