Core-shell catalyst for removing organic sulfur as well as preparation method and application of core-shell catalyst

A core-shell catalyst, organic sulfur technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., to achieve the effects of clean products, high specific surface area, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

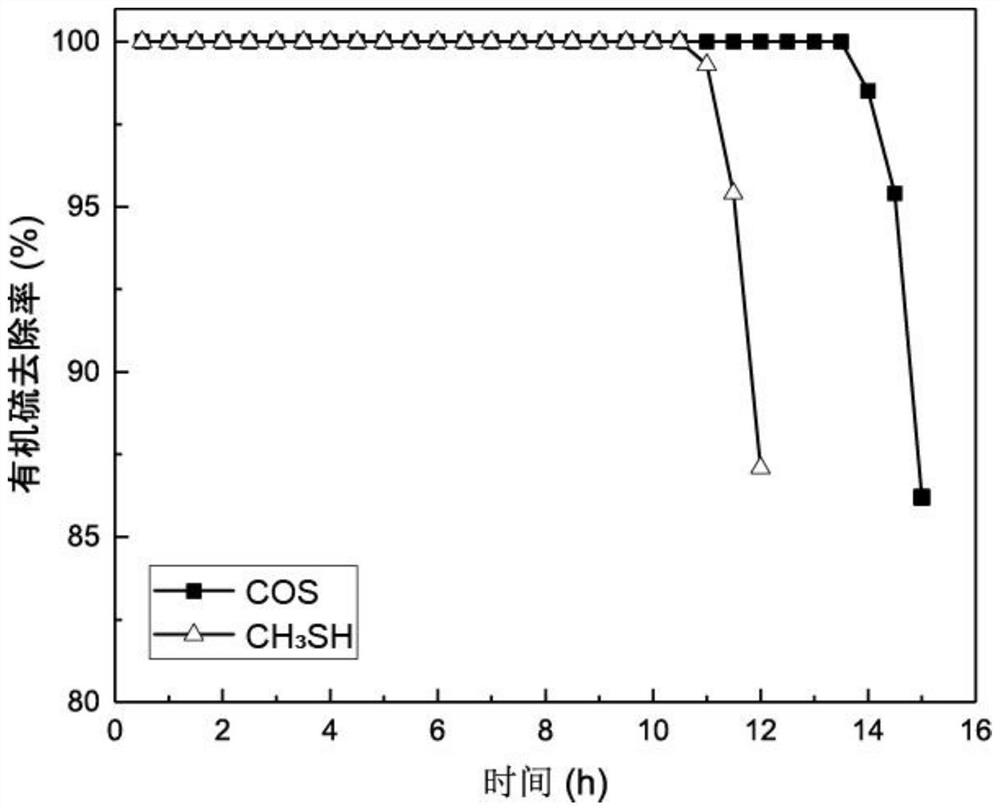

Examples

preparation example Construction

[0026] The invention provides a method for preparing a core-shell catalyst for removing organic sulfur, comprising the following steps:

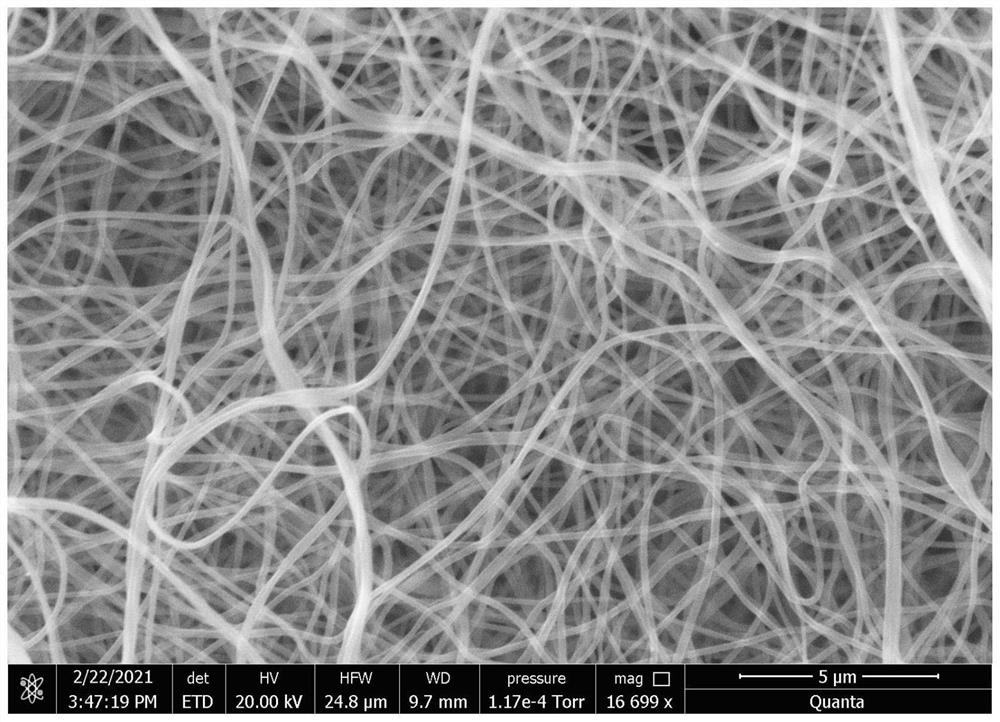

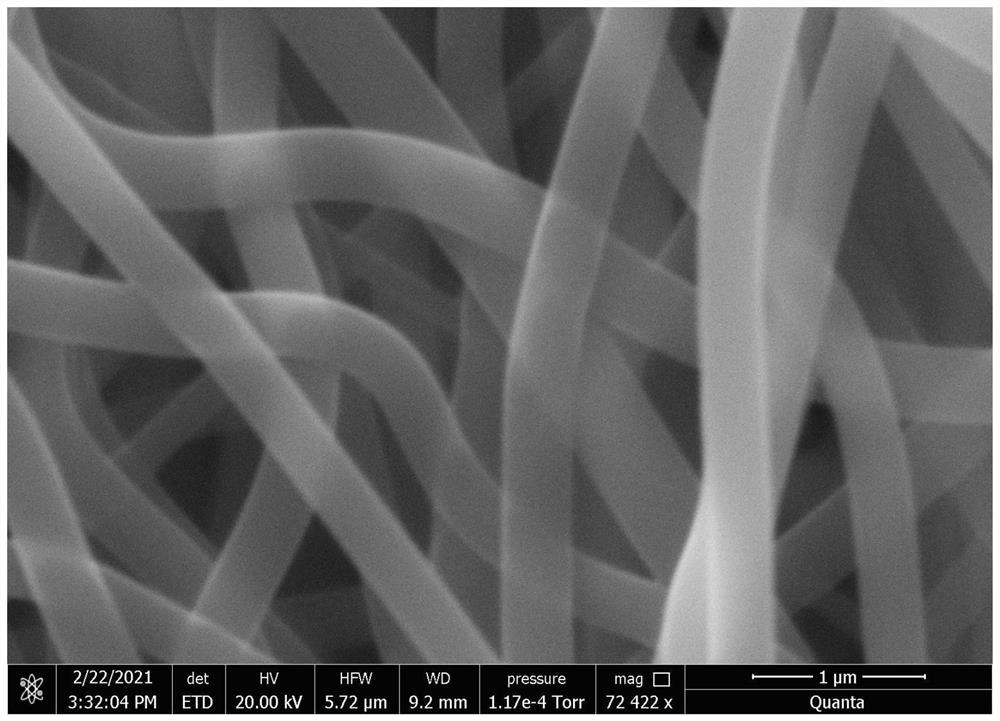

[0027] performing the first mixing of the covalent organic framework material, the first co-solvent and the first solvent, and performing electrospinning of the resulting spinning solution to obtain a fiber membrane;

[0028] The metal-organic framework material, the second co-solvent and the second solvent are mixed for the second time, and the obtained mixed solution is supported on the fiber membrane, and calcined to obtain the catalyst.

[0029] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in the art.

[0030] In the invention, the covalent organic framework material, the first co-solvent and the first solvent are first mixed, and the resulting spinning solution is electrostatically spun to obtain a fiber membrane. In the present ...

Embodiment 1

[0058] Stir and dissolve PAN (molecular weight 80000) and BF-COF-1 in DMF so that the mass concentration of PAN is 15%, the mass concentration of BF-COF-1 is 8%, the stirring speed is 200r / min, and the stirring temperature is 60°C , the stirring time was 3h, and the spinning solution was obtained;

[0059] Put the spinning liquid into the electrospinning equipment for electrospinning, the electrospinning take-up device adopts a detachable mesh drum take-up device, the voltage of the electrospinning process is 6kV, and the obtained spinning product is placed Dry in a vacuum drying oven for 3 hours under the condition of a vacuum of 0.1 MPa to obtain a fiber film;

[0060] PAN (molecular weight is 100000) and MIL-100 are stirred and dissolved in DMF, make the mass concentration of PAN be 10%, the mass concentration of MIL-100 is 15%, stirring speed is 400r / min, and stirring temperature is 80 ℃, stirring time For 5h, the mixed solution was obtained;

[0061] With the volume rat...

Embodiment 2

[0063] Stir and dissolve PAN (molecular weight: 120000) and COF-LZU1 in DMF so that the mass concentration of PAN is 10%, the mass concentration of COF-LZU1 is 10%, the stirring speed is 400r / min, the stirring temperature is 70°C, and the stirring time For 4h, obtain spinning solution;

[0064] Put the spinning liquid into the electrospinning equipment for electrospinning, the electrospinning take-up adopts a detachable mesh drum take-up, the voltage of the electrospinning process is 10kV, and the obtained spinning product is placed Dry in a vacuum drying oven for 3 hours under the condition of a vacuum degree of 0.05MPa to obtain a fiber film;

[0065] Stir and dissolve PAN (molecular weight is 80000) and MOF-5 in DMF so that the mass concentration of PAN is 12%, the mass concentration of MOF-5 is 11%, the stirring speed is 300r / min, the stirring temperature is 60°C, and the stirring time For 6h, the mixed solution was obtained;

[0066] With the volume ratio of the spinnin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com