Cable stripping device and stripping method

A cable and cable technology, applied in the field of cable stripping devices, can solve the problems of easy scratching, high labor intensity, low automation and precision, and achieve improved stripping efficiency and precision, improved versatility, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

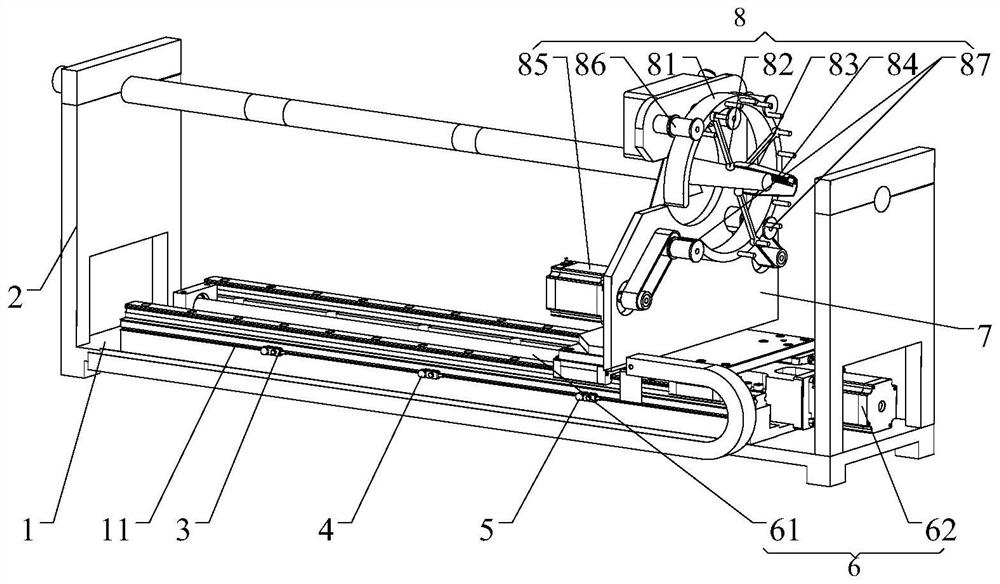

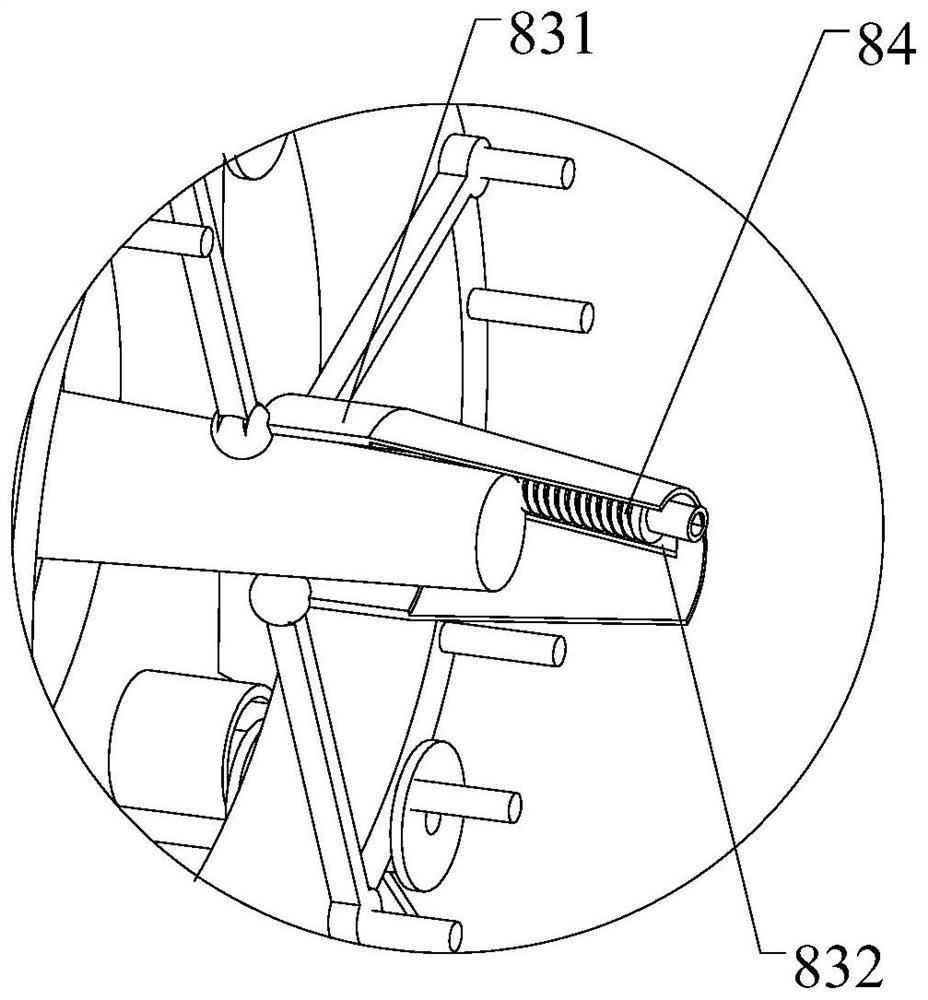

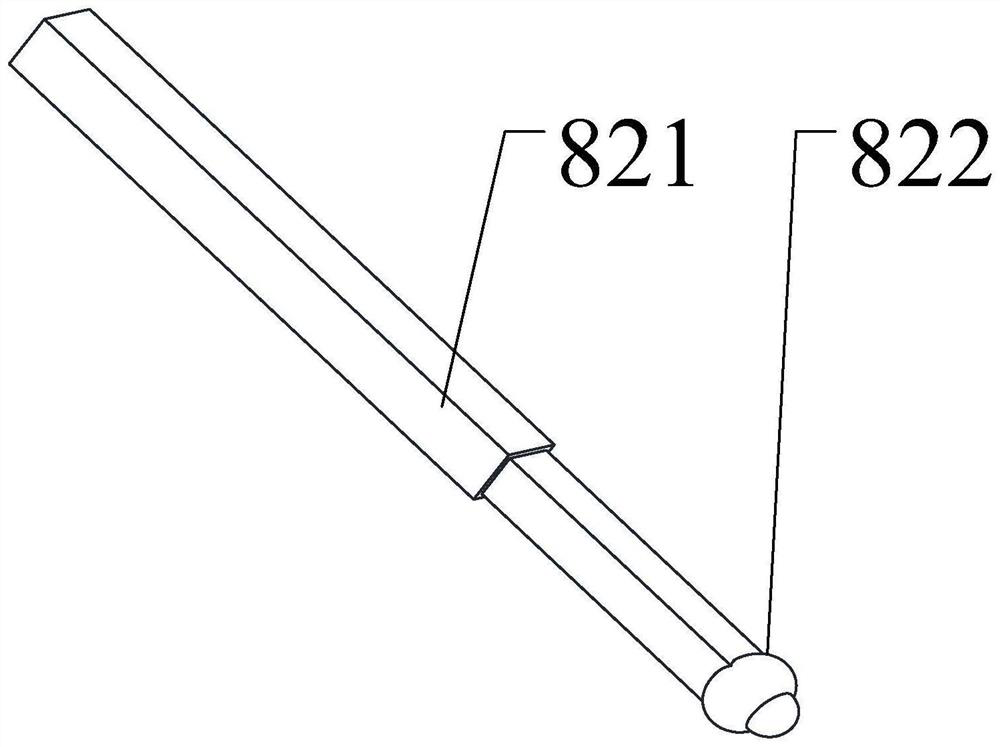

[0032] figure 1 It is a schematic structural diagram of a cable stripping device of the present invention, figure 2 It is a schematic diagram of the structure of the tool holder of the present invention, image 3 It is a schematic diagram of the structure of the telescopic spring rod of the present invention, Figure 4 It is a schematic diagram of the installation structure of the hob spring in the present invention. As shown in the figure, a cable stripping device includes a base 1 , a supporting mechanism for supporting the cable, a moving mechanism 6 , a rotating mechanism 8 and a hob bracket 7 .

[0033] The support mechanism includes two support plates 2 , which are respectively fixed to two ends of the base 1 , and the support plates 2 are provided with through holes for cables to pass through, so as to realize the basic fixation of the cables.

[0034] The moving mechanism 6 is fixed on the base 1 and includes a moving drive motor 62 and a ball screw 61. The ball scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com