System and method for predicting alkalinity of silicon-manganese alloy smelting slag

A technology of slag basicity and silicomanganese alloy, which is applied in prediction, character and pattern recognition, instruments, etc., can solve the problems of untimely feedback, prediction of slag basicity change trend and range, etc., so as to avoid large fluctuations and optimize smelting The effect of high process and calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

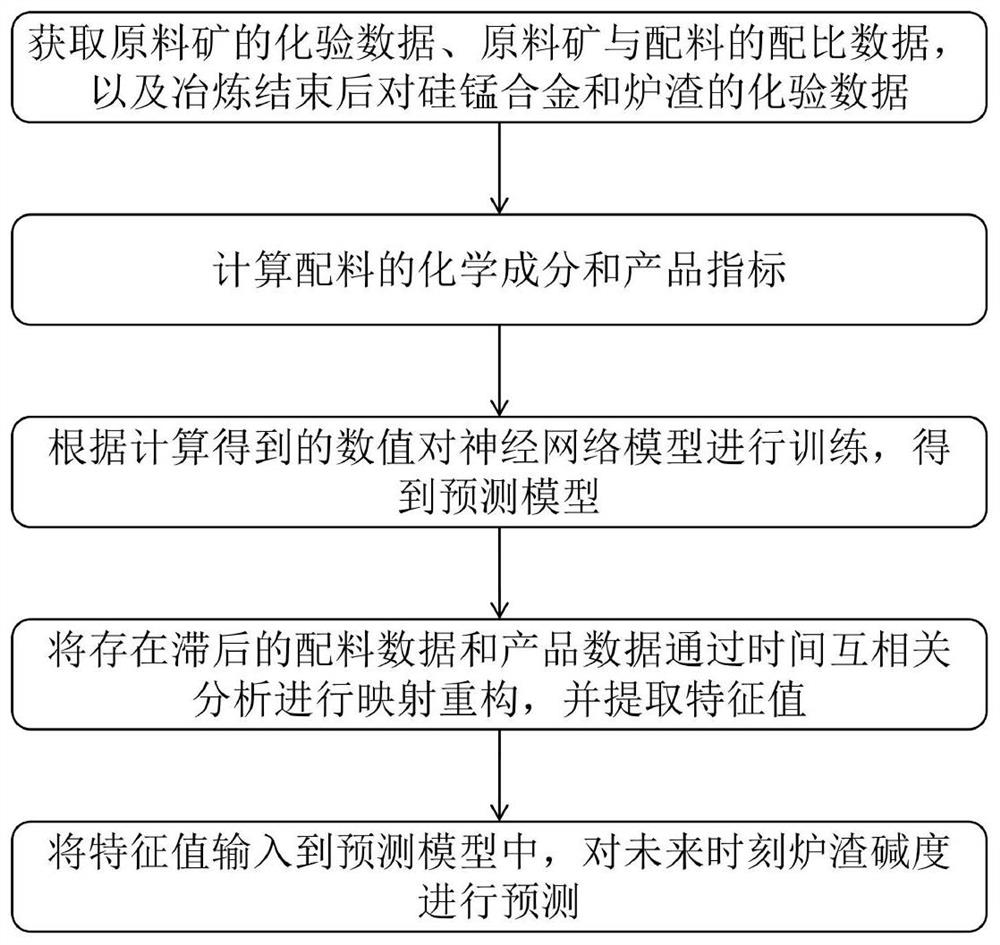

[0052] Such as figure 1 , the invention provides a method for establishing a predictive model for slag alkalinity in silicon-manganese alloy smelting, comprising the following steps:

[0053] Step 1, collect the ratio of various raw materials ore and auxiliary materials for each batching, and calculate the comprehensive moisture, manganese content, iron content, silicon content, calcium content, magnesium content, aluminum content, manganese-ferro ratio, silicon-manganese ratio, Carbon-manganese ratio, aluminum-manganese ratio, and the theoretical alkalinity of raw materials entering the furnace;

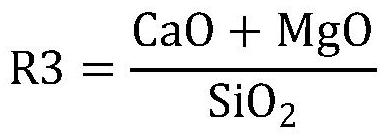

[0054] Step 2, collect the furnace data of each silicon-manganese alloy smelting, including the start time and end time of smelting, the output of the silicon-manganese alloy, the amount of slag, the manganese content in the silicon-manganese alloy, the silicon content, the manganese content in the slag, the carbon dioxide Silicon content, magnesium oxide content, calcium oxide con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com