Preparation method of interface polarization enhanced TiO2/RGO wave-absorbing material

A technology of interface polarization and wave-absorbing materials, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of weak dielectric loss capability, easy agglomeration, narrow absorption frequency band, etc., and achieve enhanced dielectric loss performance , Controllable dielectric loss performance, conductivity and conductance loss ability improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

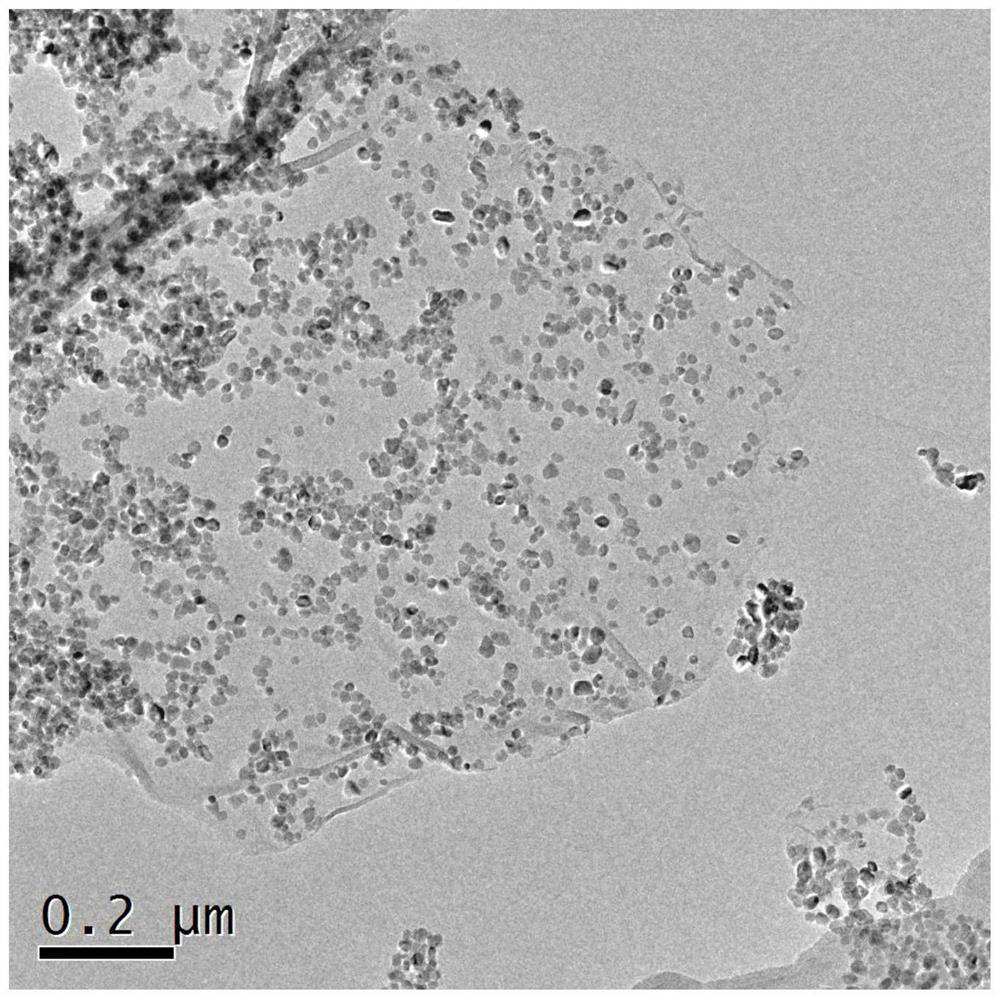

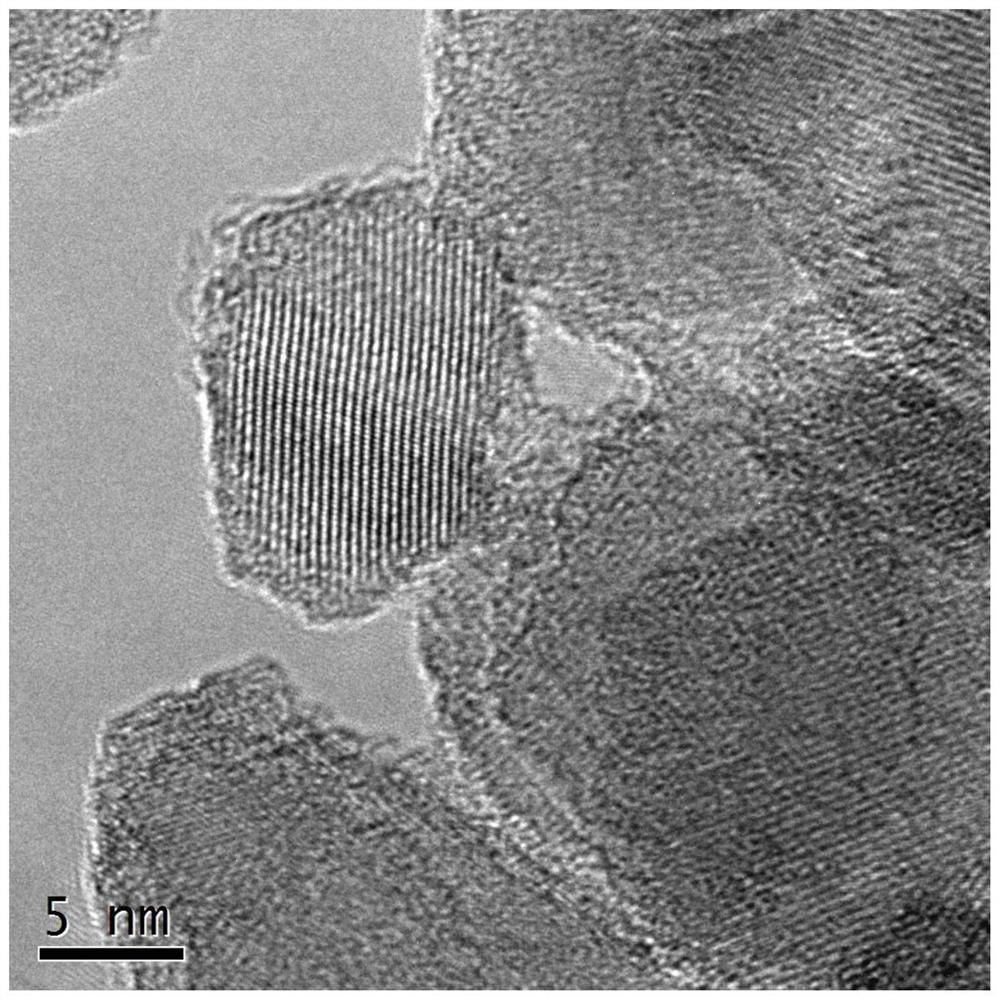

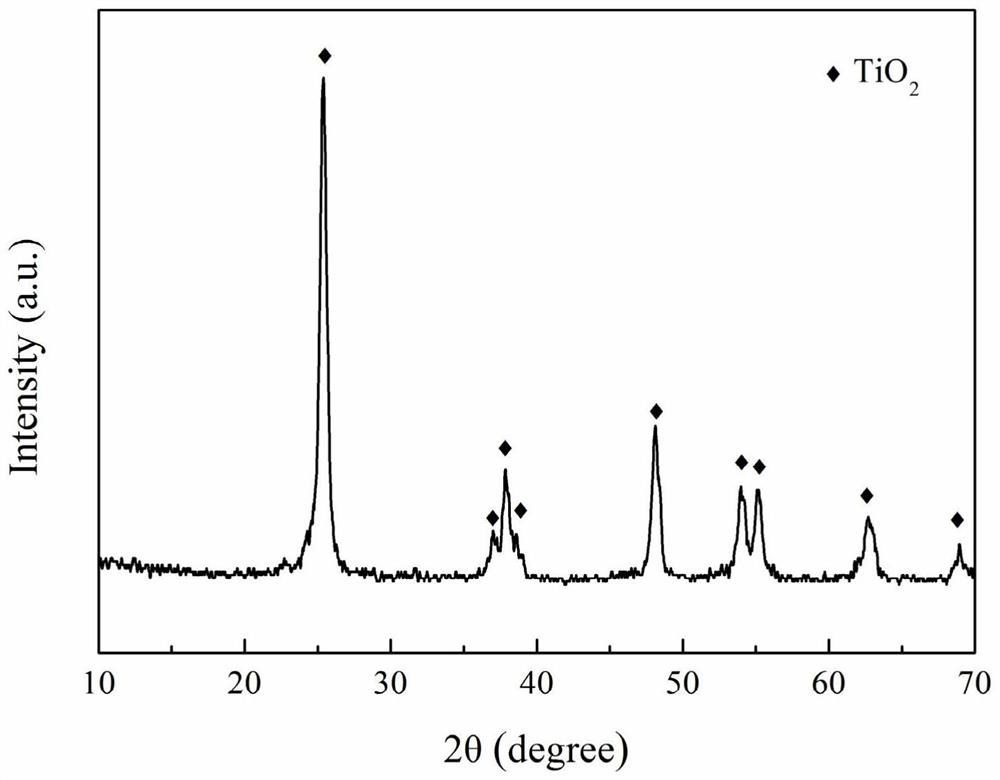

[0040] Interface Polarization Enhanced TiO 2 The preparation method of / RGO absorbing material is implemented according to the following steps:

[0041] Step 1. Disperse GO in the mixed solution of ethanol and water by ultrasonic treatment to obtain a GO suspension, then add the mixed solution of tetrabutyl titanate and ethanol, and obtain a uniform mixed solution by magnetic stirring;

[0042] The volume ratio of ethanol and water in the mixed solution of ethanol and water is 10:1, the content of GO is 0.05 mg / mL, and the molar concentration of tetrabutyl titanate in the uniform mixed solution is 0.1 mol / L.

[0043] Step 2, placing the homogeneously mixed solution of the step 1 in a polytetrafluoroethylene-lined autoclave, and obtaining a solid phase product at a high temperature;

[0044] The reaction temperature of the homogeneously mixed solution in a polytetrafluoroethylene-lined autoclave is 140° C., and the reaction time is 4 hours.

[0045] Step 3, collect the solid ...

Embodiment 2

[0050] Interface Polarization Enhanced TiO 2 The preparation method of / RGO absorbing material is implemented according to the following steps:

[0051] Step 1. Disperse GO in the mixed solution of ethanol and water by ultrasonic treatment to obtain a GO suspension, then add the mixed solution of tetrabutyl titanate and ethanol, and obtain a uniform mixed solution by magnetic stirring;

[0052] The volume ratio of ethanol and water in the mixed solution of ethanol and water is 10:1, the content of GO is 0.1 mg / mL, and the molar concentration of tetrabutyl titanate in the uniform mixed solution is 0.2 mol / L.

[0053] Step 2, placing the homogeneously mixed solution of the step 1 in a polytetrafluoroethylene-lined autoclave, and obtaining a solid phase product at a high temperature;

[0054] The reaction temperature of the homogeneously mixed solution in a polytetrafluoroethylene-lined autoclave is 150° C., and the reaction time is 6 h.

[0055] Step 3, collect the solid phase...

Embodiment 3

[0060] Interface Polarization Enhanced TiO 2 The preparation method of / RGO absorbing material is implemented according to the following steps:

[0061] Step 1. Disperse GO in the mixed solution of ethanol and water by ultrasonic treatment to obtain a GO suspension, then add the mixed solution of tetrabutyl titanate and ethanol, and obtain a uniform mixed solution by magnetic stirring;

[0062] The volume ratio of ethanol and water in the mixed solution of ethanol and water is 10:1, the content of GO is 0.15 mg / mL, and the molar concentration of tetrabutyl titanate in the uniform mixed solution is 0.25 mol / L.

[0063] Step 2, placing the homogeneously mixed solution of the step 1 in a polytetrafluoroethylene-lined autoclave, and obtaining a solid phase product at a high temperature;

[0064] The reaction temperature of the homogeneously mixed solution in a polytetrafluoroethylene-lined autoclave is 160° C., and the reaction time is 8 hours.

[0065] Step 3, collect the solid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com